Introduction: Why Corrosion is a Major Concern for Steel Deck Sheets

In the world of construction and industrial applications, galvanized steel deck sheets are a popular choice due to their durability, strength, and affordability. These sheets are coated with zinc to provide an extra layer of protection against environmental factors. However, despite the corrosion-resistant properties of galvanized steel, it is not immune to rust and deterioration over time.

In this article, we will explore why corrosion prevention is vital for galvanized steel deck sheets, and share five expert tips to help you maintain their integrity and prolong their lifespan.

What Are Galvanized Steel Deck Sheets?

Understanding Galvanized Steel

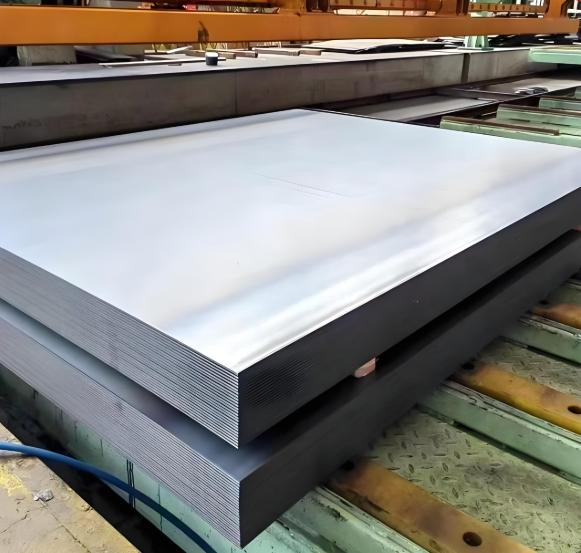

Galvanized steel deck sheets are made from steel that has been coated with a thin layer of zinc. This process, known as galvanization, helps protect the steel from corrosion, especially in harsh environments like outdoor construction sites or industrial applications where exposure to moisture is common.

The process involves immersing the steel in molten zinc, which forms a bond that offers resistance against rust, weathering, and chemical exposure. The galvanized coating is highly effective in extending the lifespan of steel deck sheets, making them a preferred option for decking, roofing, and structural applications.

Common Causes of Corrosion in Galvanized Steel Deck Sheets

Identifying the Sources of Corrosion

While galvanized steel deck sheets are designed to be resistant to corrosion, certain factors can still contribute to their deterioration over time. Some of the main causes of corrosion include:

-

Exposure to moisture: Prolonged contact with water, especially in coastal or high-humidity areas, can break down the zinc coating.

-

Chemical exposure: Acidic or alkaline substances can damage the protective layer, causing it to weaken.

-

Mechanical damage: Scratches, dents, or other physical damage to the galvanized layer can expose the steel underneath, leading to rust formation.

Tip #1: Use Protective Coatings to Enhance Corrosion Resistance

Adding a Layer of Protection

One of the best ways to prevent corrosion in galvanized steel deck sheets is by applying additional protective coatings. While galvanization provides a decent level of protection, coatings like epoxy, polyurethane, or silicone can further enhance resistance to corrosion.

-

Epoxy Coatings: Epoxy coatings create a strong, durable layer that shields galvanized steel from water, chemicals, and mechanical damage.

-

Polyurethane Coatings: These coatings are especially effective for outdoor applications as they offer resistance to UV rays, weathering, and physical wear.

-

Silicone Coatings: Known for their flexibility, silicone coatings can provide protection in environments with significant temperature fluctuations.

Tip #2: Regular Inspection and Maintenance

Catching Issues Early

Routine inspections are essential for identifying early signs of corrosion on galvanized steel deck sheets. Regular maintenance can catch problems before they escalate into serious damage. Here are a few steps to incorporate into your inspection process:

-

Look for Signs of Wear: Check for visible signs of scratches, dents, or peeling of the galvanized coating.

-

Inspect for Rust: Although the steel is coated, rust can still develop in areas where the zinc coating is compromised.

-

Check for Moisture Accumulation: Ensure that water isn’t trapped in any area of the deck sheet, as this can accelerate the corrosion process.

By performing regular checks, you can extend the lifespan of your galvanized steel deck sheets and prevent costly repairs.

Tip #3: Control the Environment to Minimize Exposure

Managing Environmental Factors

Environmental factors such as humidity, temperature, and exposure to chemicals can accelerate corrosion. By controlling these elements, you can significantly reduce the risk of corrosion.

-

Humidity Control: Install proper ventilation to reduce humidity and prevent moisture buildup on the surface of the galvanized steel.

-

UV Protection: Use UV-resistant coatings or install barriers to shield the steel from excessive sunlight.

-

Chemical Exposure: If your galvanized steel deck sheets are in an area prone to chemical exposure, consider additional protective layers to guard against corrosive substances.

Tip #4: Repair Damage Promptly to Prevent Further Deterioration

Acting Quickly to Avoid Rust Spreading

Any damage to the galvanized steel deck sheets, such as scratches or chips in the coating, should be addressed immediately. Exposed steel can rust quickly when exposed to moisture, so prompt repairs are crucial. Here’s how to handle minor repairs:

-

Clean the Area: Before applying any protective coating or repair material, clean the damaged area thoroughly.

-

Apply Zinc-Rich Paint: For small chips or scratches, use a zinc-rich paint to restore the protective coating.

-

Patch Larger Areas: For more significant damage, consider applying a new layer of galvanized coating or using a high-quality anti-corrosion spray.

Tip #5: Use the Right Materials for Construction

Choosing Complementary Materials

When using galvanized steel deck sheets in construction, it’s important to choose materials that won’t contribute to accelerated corrosion. Some materials can react with galvanized steel, causing faster deterioration. For example, using untreated aluminum or copper in direct contact with galvanized steel can lead to galvanic corrosion.

-

Stainless Steel Fasteners: Use stainless steel fasteners or screws to avoid contact corrosion with the galvanized steel.

-

Plastic or Rubber Gaskets: Consider using plastic or rubber gaskets to create a barrier between dissimilar materials and prevent corrosion from electrochemical reactions.

Case Study: Successful Corrosion Prevention in Real-World Applications

In a recent project, I worked with galvanized steel deck sheets for a roofing installation. Although the galvanized sheets were expected to resist corrosion, we applied an additional polyurethane coating as an extra safeguard. A year later, the roof remained in excellent condition, even in a high-humidity environment, thanks to the preventive steps we took.

This example highlights the importance of combining multiple methods, such as coatings and regular inspections, to ensure the longevity of galvanized steel deck sheets.

Comparing Corrosion Resistance in Different Coatings: A Detailed Analysis

Here’s a comparison of how different coatings perform in protecting galvanized steel deck sheets from corrosion:

| Coating Type | Strength against Corrosion | UV Resistance | Durability | Cost |

|---|---|---|---|---|

| Epoxy | High | Moderate | Very High | $$ |

| Polyurethane | Moderate | High | High | $$$ |

| Silicone | Moderate | Very High | Moderate | $$ |

As you can see, polyurethane coatings offer the best protection against UV rays and weathering, while epoxy provides a strong, durable shield against corrosion.

Common Mistakes to Avoid When Protecting Galvanized Steel Deck Sheets

⚠️ Mistake #1: “Only applying one coat of protection.”

Fact: In many cases, a single layer of protective coating may not be enough. Layering different coatings can offer superior protection.

⚠️ Mistake #2: “Ignoring small scratches and chips.”

Fact: Minor damage to the galvanized coating should be repaired immediately. Small issues can quickly turn into larger problems if not addressed.

Conclusion: Keeping Your Galvanized Steel Deck Sheets in Top Condition

In conclusion, corrosion prevention is critical for maintaining the integrity and longevity of galvanized steel deck sheets. By following the tips outlined in this article—such as using protective coatings, inspecting regularly, and controlling environmental factors—you can ensure that your galvanized steel sheets remain strong and reliable for years to come.

Practical Checklist for Corrosion Prevention

-

Inspect galvanized steel sheets regularly for signs of damage or corrosion.

-

Apply protective coatings like epoxy or polyurethane to enhance corrosion resistance.

-

Repair any damage promptly to prevent rust formation.

-

Control environmental factors like humidity and UV exposure.

-

Choose compatible materials to prevent galvanic corrosion.

For high-quality galvanized steel deck sheets and expert corrosion prevention, contact Shanxi Luokaiwei Steel Company:

-

Email: [email protected]

-

WhatsApp: +86 18912200505