The Importance of Understanding 18 Galvanized Steel Sheet Weight

When working with 18 galvanized steel sheets, it’s essential to understand their weight, especially for large construction or manufacturing projects. Knowing the precise weight of each sheet helps in accurate calculations for material requirements, shipping, and proper handling during installation. In this article, we will explore the 18 galvanized steel sheet weight chart, offer practical installation tips, and discuss why weight matters in your projects.

What is an 18 Galvanized Steel Sheet?

Key Features and Specifications

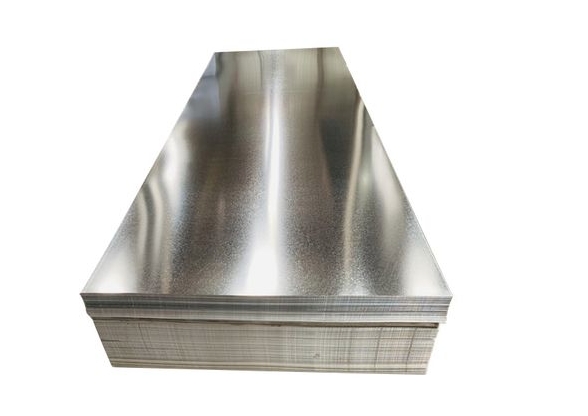

An 18 galvanized steel sheet is a steel sheet with a thickness of 0.048 inches (1.22mm). Galvanization refers to the process of coating the steel with zinc, which provides enhanced corrosion resistance. The weight of a sheet depends on its thickness, dimensions, and the coating applied. For example, 18 galvanized steel sheets typically have a moderate weight, making them ideal for roofing, cladding, and structural applications.

The galvanized coating helps protect the steel from environmental factors such as moisture, air, and chemicals. This makes 18 galvanized steel sheets a popular choice for both indoor and outdoor projects.

The Importance of Weight in 18 Galvanized Steel Sheets

1. Calculating Material Requirements

Understanding the weight of 18 galvanized steel sheets is essential when planning your material requirements. For example, if you need to calculate how many sheets you’ll require for a roofing project, knowing the exact weight of each sheet will help you order the right amount of material and avoid excess or shortage.

2. Ensuring Proper Handling and Safety

Proper handling is crucial when working with 18 galvanized steel sheets due to their weight. Overloading scaffolding or lifting equipment can lead to accidents or material damage. Knowing the weight allows for better planning and ensures that the right tools are used for safe handling.

3. Cost Estimation and Budgeting

The weight of 18 galvanized steel sheets plays a role in shipping costs and overall project expenses. Heavier sheets may result in higher transportation costs, so having an accurate weight calculation helps in estimating total project costs more effectively.

18 Galvanized Steel Sheet Weight Chart

Here is a weight chart for 18 galvanized steel sheets, based on standard dimensions of 4 feet by 8 feet (1.22m x 2.44m):

| Thickness (inches) | Weight per Square Foot (lbs) | Weight per Sheet (lbs) (4’ x 8’) |

|---|---|---|

| 0.048 (18 gauge) | 2.35 | 75.2 |

| 0.060 (16 gauge) | 2.90 | 93.6 |

| 0.072 (14 gauge) | 3.45 | 111.2 |

Explanation:

-

Weight per Square Foot (lbs): This is the weight of the steel sheet per square foot.

-

Weight per Sheet (lbs): The weight of the entire sheet, calculated for the standard 4’ x 8’ dimensions.

This chart is essential for anyone looking to calculate the weight of 18 galvanized steel sheets for their project, whether for shipping, structural calculations, or installation planning.

Pro Installation Tips for 18 Galvanized Steel Sheets

1. Proper Handling During Installation

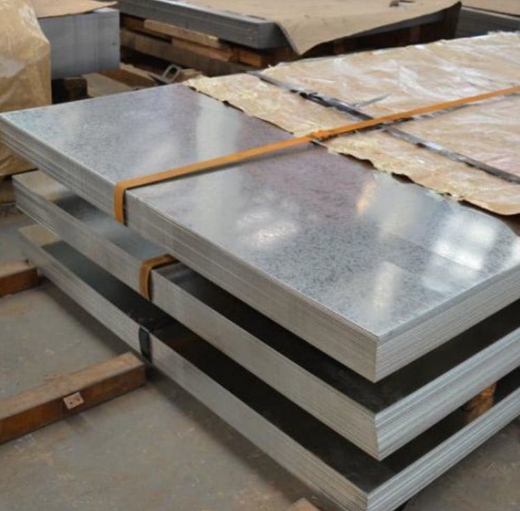

When working with 18 galvanized steel sheets, proper handling is crucial to prevent damage to the material. The moderate weight of these sheets requires careful lifting and positioning. Using mechanical lifts or cranes can help distribute the weight evenly. Avoid dragging the sheets across rough surfaces to prevent scratches that could damage the galvanized coating.

2. Use the Right Fasteners and Tools

For a secure and stable installation, using the right fasteners and tools is essential. The 18 galvanized steel sheet should be secured with stainless steel screws or self-drilling screws to ensure a firm attachment without causing damage to the coating. Regular steel fasteners can rust over time, compromising the integrity of the steel.

-

Tip: Make sure that the screws are long enough to go through the thickness of the sheet but short enough to avoid damaging the surface underneath.

3. Plan for Expansion and Contraction

Steel sheets, including 18 galvanized steel sheets, expand and contract with temperature changes. This means that during installation, you need to leave some space between sheets to accommodate expansion. Not accounting for this could cause buckling or warping as the material moves with temperature fluctuations.

4. Work in Ideal Weather Conditions

While galvanized steel is highly durable, it’s important to avoid installing 18 galvanized steel sheets in extreme weather conditions. Cold, wet, or windy conditions can make handling the material difficult and increase the risk of damage. Ideally, install the sheets when the weather is dry and moderate, and avoid installation during rainfall to protect the coating from corrosion.

Real-World Application: Installing 18 Galvanized Steel Sheets in Roofing

Case Study: Commercial Roof Installation

In one of our recent projects, we installed 18 galvanized steel sheets on the roof of a commercial warehouse. The project required precise calculations for material weight, as we had to ensure the weight of the steel would not overload the structural framework. Using the 18 galvanized steel sheet weight chart, we ordered the exact number of sheets needed, ensuring proper weight distribution across the roof.

During installation, we used a mechanical lift to move the sheets onto the roof, reducing the physical strain on our team and minimizing the risk of damaging the sheets. The installation was completed smoothly, and the roof has performed excellently in terms of both durability and corrosion resistance.

Comparison: 18 Galvanized Steel Sheet vs. Other Steel Thicknesses

Here’s a comparison between 18 galvanized steel sheets and other steel thicknesses used in construction and industrial applications:

| Feature | 18 Galvanized Steel Sheet (0.048”) | 16 Galvanized Steel Sheet (0.060”) | 14 Galvanized Steel Sheet (0.072”) |

|---|---|---|---|

| Weight per Square Foot | 2.35 lbs | 2.90 lbs | 3.45 lbs |

| Strength | Moderate | High | Very High |

| Cost | Lower | Moderate | Higher |

| Flexibility | High | Moderate | Low |

| Applications | Roofing, cladding, light structure | Heavy-duty roofing, industrial walls | Structural beams, heavy machinery |

Analysis:

-

18 Galvanized Steel Sheet: Ideal for lighter applications such as roofing and cladding, offering a balance between cost and performance.

-

16 Galvanized Steel Sheet: Offers higher strength and is better suited for industrial walls and heavier-duty roofing.

-

14 Galvanized Steel Sheet: Provides the highest strength and is used for structural support in heavy-duty machinery and large-scale construction.

Common Misconceptions About 18 Galvanized Steel Sheets

⚠️ Misconception 1: “Thicker sheets always provide better corrosion resistance.”

Fact: While thicker sheets may offer more strength, 18 galvanized steel sheets with proper galvanization and the right coating (such as 55% Al-Zn) can provide excellent corrosion resistance without the extra weight.

⚠️ Misconception 2: “Galvanized steel sheets are the same regardless of thickness.”

Fact: The thickness of the sheet impacts its weight, strength, and suitability for different applications. 18 galvanized steel sheets are more flexible and suitable for lighter applications, whereas thicker sheets are better suited for heavy-duty tasks.

Conclusion

18 galvanized steel sheets are an excellent material choice for a wide range of applications, offering a balance of strength, durability, and cost-effectiveness. By understanding the weight and properties of 18 galvanized steel sheets, and following best practices for installation, you can ensure your project runs smoothly and lasts for years.

Practical Checklist for Installing 18 Galvanized Steel Sheets

-

Review material requirements and calculate the weight of sheets needed for your project.

-

Choose the right fasteners and tools for secure installation.

-

Plan for temperature expansion by leaving adequate space between sheets.

-

Install in favorable weather conditions to prevent material damage.

-

Inspect sheets for damage before installation to ensure integrity.

For high-quality 18 galvanized steel sheets and expert installation advice, contact Shanxi Luokaiwei Steel Company:

-

Email: [email protected]

-

WhatsApp: +86 18912200505