The Role of Hot Dipped 10 Gauge Galvanized Steel Sheets

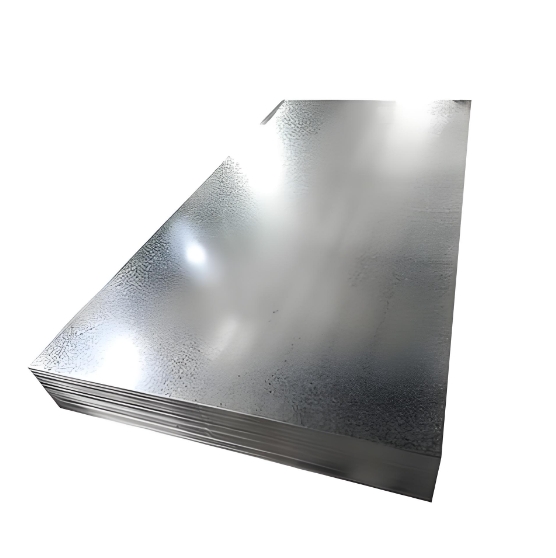

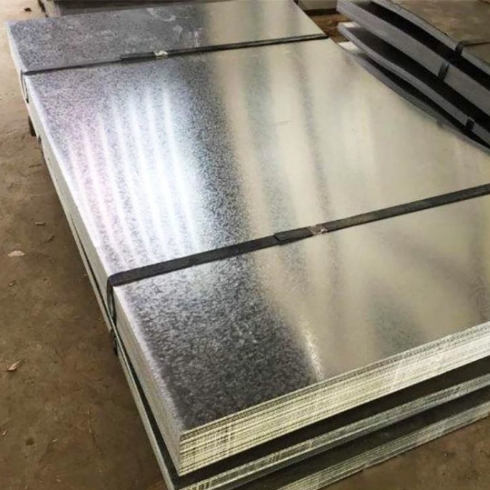

In construction, automotive, and various industrial sectors, the demand for durable, long-lasting materials is critical. One such material that stands out for its superior performance is the 10 gauge galvanized steel sheet, particularly those with a 55% Al-Zn coating. Known for its enhanced corrosion resistance and strength, this steel sheet has become an industry standard for applications exposed to harsh environmental conditions.

This article will delve into the benefits, applications, and technical details of hot dipped 10 gauge galvanized steel sheets with a 55% Al-Zn coating, providing insights into why this material is an excellent choice for a wide range of projects.

What is a 10 Gauge Galvanized Steel Sheet?

Definition and Specifications

A 10 gauge galvanized steel sheet is a steel sheet that is 0.1345 inches (3.43 mm) thick, offering a robust solution for construction, automotive, and industrial applications. The steel sheet is coated using a hot-dip galvanizing process, in which the steel is dipped into molten zinc, providing excellent corrosion resistance.

In the case of the 55% Al-Zn coating, a mixture of 55% aluminum and 45% zinc is used, which significantly improves the material’s resistance to oxidation and corrosion. This coating makes the steel highly durable, especially in high-temperature environments, and extends the material’s lifespan, making it an ideal choice for many outdoor applications.

Benefits of 55% Al-Zn Coating

1. Superior Corrosion Resistance

The 55% Al-Zn coating offers superior protection compared to traditional galvanized coatings. The combination of aluminum and zinc provides a double layer of protection, significantly enhancing resistance to corrosion. This is particularly beneficial in harsh environments like coastal areas or industrial sites, where exposure to moisture, salts, and chemicals is common.

-

Zinc: Primarily responsible for galvanic protection, sacrificing itself to protect the steel underneath.

-

Aluminum: Provides a barrier that prevents oxygen and water from reaching the steel surface, offering additional protection and heat resistance.

2. Longer Service Life

The 55% Al-Zn coating significantly extends the life of 10 gauge galvanized steel sheets compared to traditional galvanized coatings. According to a study by American Galvanizers Association, the lifespan of steel with an Al-Zn coating can be up to 4-6 times longer than that of conventional galvanized steel in outdoor environments.

Applications of 10 Gauge Galvanized Steel Sheets

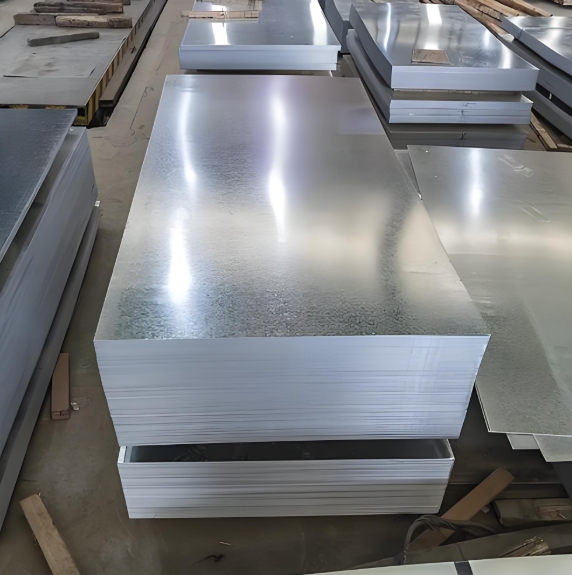

1. Roofing and Cladding

The 10 gauge galvanized steel sheet with a 55% Al-Zn coating is widely used in the roofing and cladding of buildings. The corrosion resistance offered by the coating ensures that the material can withstand the elements for many years without deteriorating.

2. Automotive Industry

In the automotive industry, 10 gauge galvanized steel sheets are used in parts that require both strength and resistance to rust. The 55% Al-Zn coating ensures that components like chassis, body panels, and undercarriages can resist corrosion from road salts, moisture, and other harsh conditions.

3. Industrial and Agricultural Equipment

The combination of strength and corrosion resistance makes 10 gauge galvanized steel sheets ideal for industrial and agricultural machinery. These sheets are used in equipment exposed to extreme weather conditions, such as storage tanks, agricultural structures, and manufacturing equipment.

How to Select the Right Hot Dipped 10 Gauge Galvanized Steel Sheet

1. Consider Corrosion Resistance Needs

If your project is exposed to harsh environmental conditions, like salty or humid air, the 55% Al-Zn coating is ideal for added protection. If your application doesn’t face significant corrosion risks, a standard galvanized steel sheet might be sufficient.

2. Determine Strength Requirements

10 gauge galvanized steel sheets provide good strength, but for certain applications requiring higher tensile strength, consider upgrading to thicker sheets or different alloys like hot rolled steel plates.

3. Evaluate Cost-Effectiveness

While the 55% Al-Zn coated sheets offer superior protection, they may come at a higher price point than traditional galvanized sheets. For long-term projects, this extra cost is justified by the increased lifespan of the material.

Real-World Application: Roofing with 10 Gauge Galvanized Steel Sheets

Case Study: Industrial Roof Cladding

In a recent project where we installed a roof for an industrial facility, we opted for 10 gauge galvanized steel sheets with a 55% Al-Zn coating. The roof was exposed to constant moisture from nearby chemical plants, and we knew that using a standard galvanized sheet would lead to rusting within a few years. With the 55% Al-Zn coated sheets, the roof has maintained its integrity for over five years without any signs of corrosion, even after prolonged exposure to aggressive chemicals.

This project illustrates the importance of selecting the right material for the job, and how the 55% Al-Zn coating can significantly extend the life of the structure.

Comparison: 55% Al-Zn Coating vs. Standard Galvanized Steel

Here’s a comparison table that shows how 55% Al-Zn coated steel sheets stack up against standard galvanized steel:

| Property | 55% Al-Zn Coating | Standard Galvanized Coating |

|---|---|---|

| Corrosion Resistance | High | Moderate |

| Cost | Higher | Lower |

| Lifespan | 4-6 times longer | Shorter |

| Temperature Resistance | Higher | Lower |

| Application | Harsh environments | Mild to moderate conditions |

Analysis:

-

55% Al-Zn Coating: Provides better protection in coastal and industrial environments but comes at a higher price.

-

Standard Galvanized Coating: Suitable for mild environments but may not last as long or provide as much protection.

Common Misconceptions About 10 Gauge Galvanized Steel Sheets

⚠️ Misconception 1: “The thicker the sheet, the more corrosion resistance it provides.”

Fact: While thickness can affect strength, the coating material, such as 55% Al-Zn, plays a much more significant role in corrosion resistance.

⚠️ Misconception 2: “Galvanized steel is not suitable for harsh environments.”

Fact: 10 gauge galvanized steel sheets with a 55% Al-Zn coating offer excellent corrosion resistance, even in aggressive industrial and marine environments.

How to Order 10 Gauge Galvanized Steel Sheets

Here’s a step-by-step guide for purchasing 10 gauge galvanized steel sheets:

-

Determine the Coating Type: Choose between 55% Al-Zn coating for harsh environments or standard galvanization for milder conditions.

-

Specify the Dimensions: Provide the supplier with the exact thickness, width, and length needed for your project.

-

Check for Certification: Ensure that the sheets meet the relevant industry standards and certifications.

-

Request Samples: If possible, order samples to check the material’s suitability before placing a bulk order.

-

Confirm Delivery: Verify that the supplier can meet your delivery schedule, especially for large or custom orders.

Conclusion: Choosing the Right Steel for Long-Term Durability

10 gauge galvanized steel sheets with a 55% Al-Zn coating offer a combination of durability, strength, and excellent corrosion resistance, making them a top choice for various industrial, construction, and automotive applications. By understanding the benefits and applications of this material, you can make informed decisions that will benefit your projects in the long run.

Practical Checklist for Ordering 10 Gauge Galvanized Steel Sheets

-

Assess environmental conditions before choosing the coating type.

-

Specify dimensions and custom cutting requirements.

-

Ensure material certifications are provided.

-

Request product samples to verify suitability.

-

Confirm delivery terms to meet your project timelines.

For high-quality 10 gauge galvanized steel sheets with 55% Al-Zn coating, contact Shanxi Luokaiwei Steel Company:

-

Email: [email protected]

-

WhatsApp: +86 18912200505