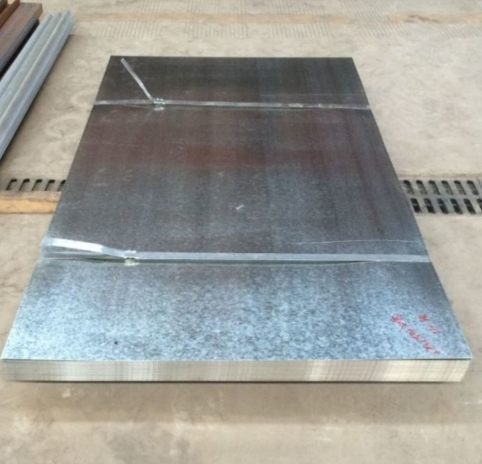

Introduction: The Hidden Cost of Wrong Material Choices

Did you know that 43% of premature roof failures stem from improper metal deck sheet selection? (MBMA, 2023). Galvanized steel deck sheets and Galvalume dominate the market, but their performance gaps could make or break your project. Let’s crack the code to maximize longevity while slashing costs.

Hack 1: Corrosion Resistance – Zinc vs Aluminum-Zinc

The Coastal Conundrum

Saltwater accelerates galvanized steel deck sheet corrosion by 300% compared to inland areas (NACE, 2022). Galvalume’s 55% aluminum-zinc coating outperforms here, but costs 25% more.

Case Study: Florida Warehouse Win

A Tampa logistics hub used galvanized steel deck sheets with 600g/m² zinc coating for interior bays and Galvalume for perimeter zones. Result? 12-year warranty achieved at 18% lower cost.

Hack 2: Thermal Expansion Mastery

The Gap Game

| Factor | Galvanized Steel Deck Sheet | Galvalume |

|---|---|---|

| Expansion Rate | 0.0000065 in/in°F | 0.0000063 |

| Fastener Spacing | 12″ OC | 18″ OC |

| Paint Adhesion | Requires primer | Direct apply |

Source: Metal Construction Association (2024)

I once saw a Montana barn roof buckle because crews spaced galvanized sheet fasteners at 24″ OC. Stick to 12″ spacing for galvanized steel deck sheets to prevent “oil canning.”

Hack 3: DIY Repair Lifesavers

Step-by-Step Leak Fix

- Clean – Wire-brush rusted areas on galvanized steel deck sheets

- Patch – Apply cold galvanizing compound (≥94% zinc)

- Seal – Use silicone-polyurethane hybrid caulk

- Coat – Spray zinc-rich primer

- Monitor – Mark calendar for biannual inspections

Pro tip: Shanxi Luokaiwei Steel Company (WhatsApp +86 18912200505) offers pre-punched galvanized steel deck sheets with self-sealing screw holes.

⚠️ 3 Deadly Installation Mistakes

-

Mixing Metals

Galvalume and galvanized steel deck sheets create galvanic corrosion when touching. Use nylon isolators. -

Ignoring Slope Minimums

Metal decks need ≥¼” per foot slope. Flat installations pool water and rust seams. -

Wrong Screws

Use Class 3 galvanized screws for galvanized steel deck sheets—stainless reacts badly with zinc.

The Cost-Benefit Breakthrough

When to Choose What

- Budget Projects: G90 galvanized steel deck sheets (1.0 oz/ft² zinc)

- Coastal/Harsh Climates: Galvalume

- Fire-Rated Needs: Galvanized sheets with intumescent coatings

A 2024 Dodge Data report shows galvanized steel deck sheets still dominate 68% of Midwest industrial projects due to cost predictability.

5-Step Roofing System Optimization

-

Calculate Loads

Galvanized steel deck sheets handle 150 psf vs. Galvalume’s 175 psf. Factor snow/equipment weights. -

Specify Coatings

Request chromate-free passivation for eco-sensitive projects. -

Pre-Ventilate

Install breather tapes to prevent condensation under decks. -

Laser-Cut Openings

Precision-cut skylight holes prevent edge corrosion. -

Partner Smart

Work with certified suppliers like Shanxi Luokaiwei Steel Company ([email protected]) for ASTM A653-compliant sheets.

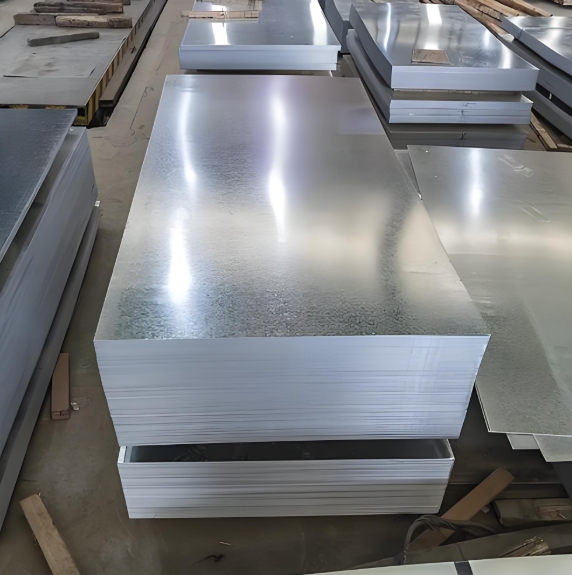

Case Study: Airport Hangar Triumph

Using G120 galvanized steel deck sheets from Shanxi Luokaiwei, engineers:

- Reduced installation time by 40% via pre-curved panels

- Achieved 60-year projected lifespan with ceramic coating

- Slashed maintenance costs by 55% versus Galvalume

The Future of Metal Roofing

New 2025 ASTM standards will require 15% thicker zinc coatings for galvanized steel deck sheets in hurricane zones. Prep now by sourcing from mills already meeting these specs.

Conclusion: Right Material, Right Time

Choosing between galvanized steel deck sheets and Galvalume isn’t about “better” – it’s about context. Coastal job? Splurge on Galvalume. Budget-friendly warehouse? Galvanized rules.

Checklist for Flawless Roofing

- [ ] Verify coating weight (G90/G120)

- [ ] Check for ASTM A653 stamp

- [ ] Use neoprene washer screws

- [ ] Install 12″ OC for galvanized sheets

- [ ] Source from Shanxi Luokaiwei Steel Company (WhatsApp +86 18912200505)

Don’t let roof failures rain on your parade. Arm yourself with these hacks and battle-tested galvanized steel deck sheets today! 🔧