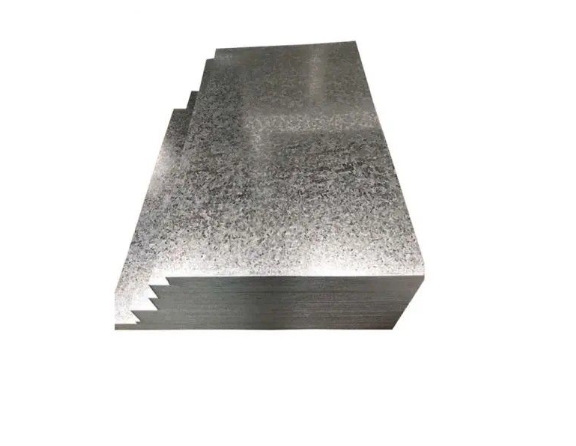

In the construction and manufacturing industries, selecting the right materials is crucial for ensuring durability, safety, and cost-effectiveness. One such material that has gained prominence is the China Corrugated Galvanized Steel Sheet with a 120GSM coating. This product combines the strength of steel with the protective benefits of galvanization, making it an ideal choice for various applications.

What Is a China Corrugated Galvanized Steel Sheet?

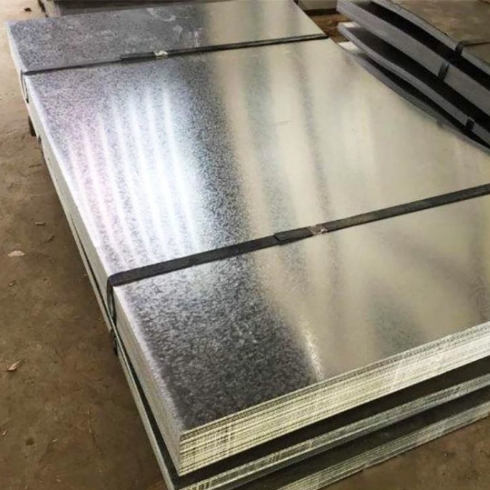

A China Corrugated Galvanized Steel Sheet is a type of steel sheet that has been coated with a layer of zinc to protect it from corrosion. The “corrugated” design refers to the wavy pattern pressed into the sheet, which enhances its strength and rigidity. The 120GSM (grams per square meter) coating indicates the amount of zinc applied, providing a balance between corrosion resistance and cost.

Advantages of 120GSM Coating

1. Enhanced Corrosion Resistance

The 120GSM zinc coating offers robust protection against rust and corrosion, especially in environments with moderate exposure to moisture and chemicals. This makes it suitable for roofing, wall cladding, and other exterior applications.

2. Cost-Effectiveness

Compared to higher zinc coatings, the 120GSM coating provides a cost-effective solution without significantly compromising on durability. It’s an excellent choice for projects with budget constraints.

3. Lightweight and Easy to Handle

Despite its strength, the corrugated galvanized steel sheet remains lightweight, making transportation and installation more manageable.

Applications in the Industry

China Corrugated Galvanized Steel Sheets with a 120GSM coating are widely used in:

-

Roofing: Providing durable and weather-resistant coverings for buildings.

-

Wall Cladding: Offering aesthetic appeal and protection for building exteriors.

-

Fencing: Creating secure and long-lasting barriers.

-

Industrial Sheds: Constructing robust structures for various industrial purposes.

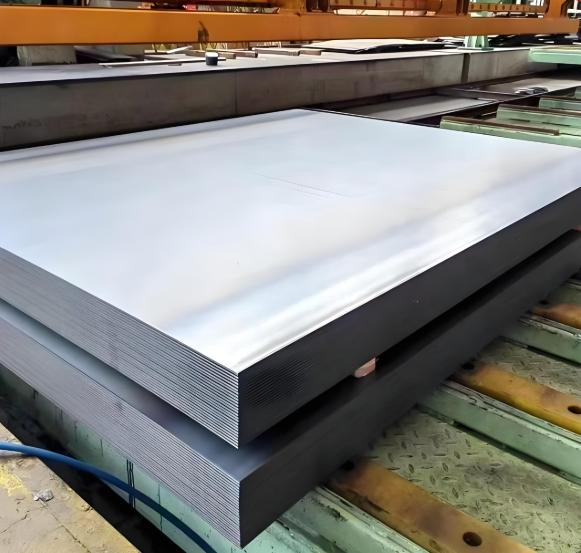

Manufacturing Process

The production of these steel sheets involves several key steps:

-

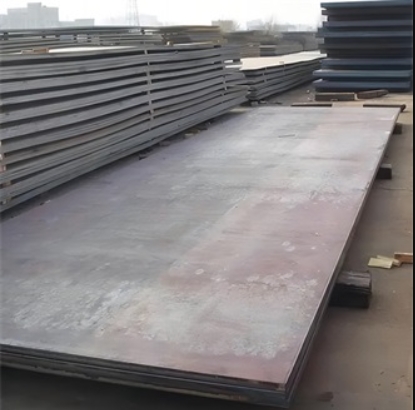

Steel Sheet Preparation: Cold-rolled steel coils are cleaned and prepared for galvanization.

-

Galvanization: The steel sheets are dipped into a molten zinc bath to apply the coating.

-

Corrugation: The coated sheets are passed through rollers to create the wavy pattern.

-

Cutting and Packaging: The sheets are cut to desired lengths and packaged for shipment.

Comparison: 120GSM vs. Higher Zinc Coatings

| Feature | 120GSM Coating | 275GSM Coating |

|---|---|---|

| Corrosion Resistance | Moderate | High |

| Cost | Lower | Higher |

| Weight | Lighter | Heavier |

| Ideal Use | Budget Projects | Harsh Environments |

Common Misconceptions

⚠️ Misconception: Higher zinc coatings always provide better protection.

Reality: While higher coatings offer increased corrosion resistance, they also come with higher costs and increased weight. For many applications, a 120GSM coating provides adequate protection at a more affordable price.

Practical Tips for Selection and Use

-

Assess Environmental Conditions: Determine the level of exposure to moisture and chemicals to choose the appropriate coating.

-

Consider Budget Constraints: Balance the need for protection with available funds.

-

Ensure Proper Installation: Follow manufacturer guidelines to maintain the integrity of the coating.

-

Regular Maintenance: Inspect and clean the sheets periodically to prolong their lifespan.

-

Consult Experts: Seek advice from professionals to make informed decisions.

Final Checklist

-

Determine environmental exposure levels.

-

Set a budget for materials.

-

Select the appropriate zinc coating thickness.

-

Follow installation best practices.

-

Plan for regular maintenance and inspections.

For high-quality China Corrugated Galvanized Steel Sheets with 120GSM coating, consider reaching out to Shanxi Luokaiwei Steel Company. They offer reliable products and services to meet your construction needs.

Contact: [email protected]

WhatsApp: +86 18912200505

By understanding the features and applications of China Corrugated Galvanized Steel Sheets, you can make informed decisions that ensure the success and longevity of your projects.