The Role of GI Sheet Galvanized Steel Coils in Modern Industry

In the world of construction, automotive manufacturing, and home appliances, GI sheet galvanized steel coils are invaluable materials. Known for their excellent strength, durability, and resistance to corrosion, these coils are used in a variety of applications. However, while they offer numerous benefits, the cost of purchasing these materials can be significant. This article reveals five expert cost-saving secrets for sourcing and using GI sheet galvanized steel coils effectively without compromising quality.

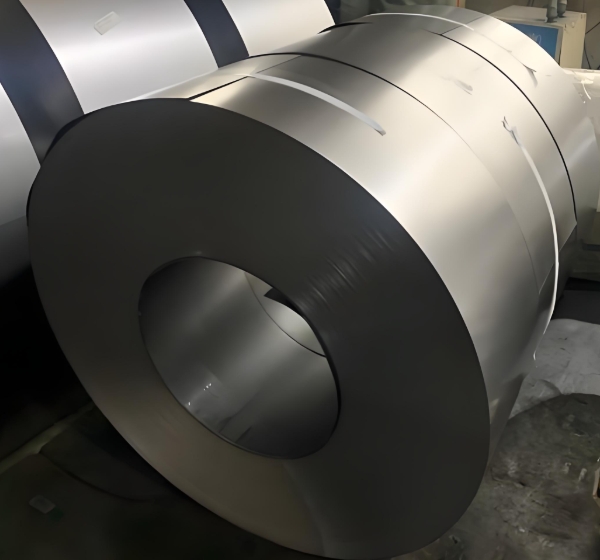

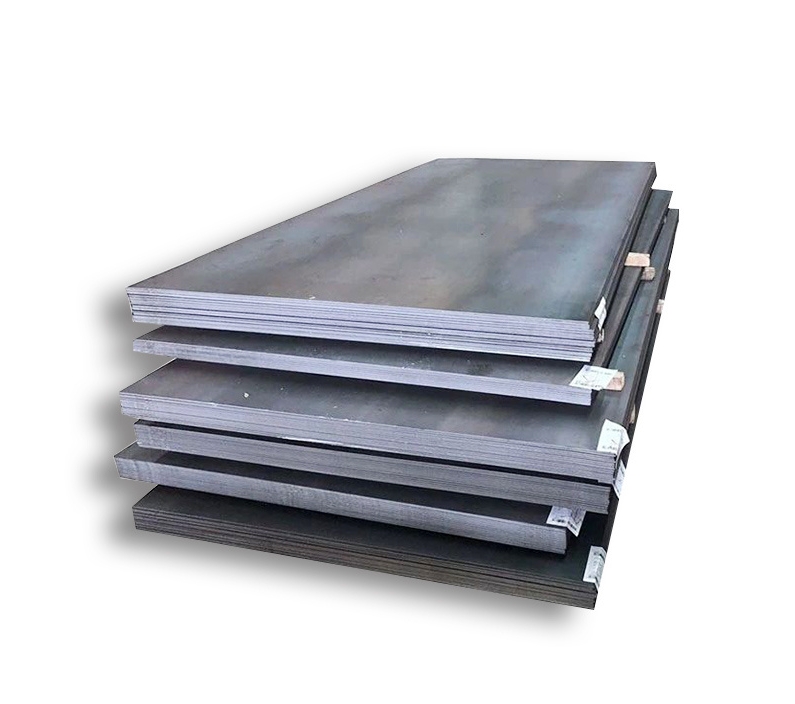

What is a GI Sheet Galvanized Steel Coil?

Definition and Key Features

GI sheet galvanized steel coil refers to steel coils that are coated with a layer of zinc through a process known as galvanization. This coating provides excellent resistance to rust, corrosion, and environmental damage, making the coils ideal for use in outdoor and industrial applications. The thickness of the galvanized coating can vary, but the most common type is the hot-dipped variety.

The GI sheet galvanized steel coil is available in various gauges, with thicknesses ranging from light to heavy-duty options. These coils are widely used in industries that require both strength and protection from corrosion, such as construction, roofing, and automotive manufacturing.

Why Understanding the Costs of GI Sheet Galvanized Steel Coils is Important

The Challenge of High Material Costs

As with any industrial material, the cost of GI sheet galvanized steel coils can be a significant factor in overall project expenses. Factors such as market prices for raw materials, the cost of galvanization, and transportation all contribute to the final price.

To optimize costs, it’s important to consider not just the base price of the coils but also factors like durability, long-term performance, and the potential for reduced maintenance costs over time. By making informed decisions, companies can balance initial investments with long-term savings.

Secret 1: Purchase in Bulk to Save Big

Why Bulk Purchases Can Lower Costs

One of the most effective ways to save money on GI sheet galvanized steel coils is by purchasing in bulk. When you order large quantities, suppliers often offer significant discounts. This is especially beneficial for companies that require a steady supply of steel for ongoing projects.

Example: Bulk Purchase Discount

In one of my projects, we needed a large quantity of GI sheet galvanized steel coils for the construction of a commercial warehouse. By purchasing in bulk, we saved approximately 15% compared to the price per unit of smaller orders. This resulted in a considerable reduction in the overall material costs for the project.

Secret 2: Opt for Standard Specifications

Avoid Over-Specifying Materials

While it’s tempting to order GI sheet galvanized steel coils with high-end coatings or specialized dimensions, often a standard specification will suffice for most projects. Customizations or premium coatings can significantly increase the cost, but they may not provide the additional benefits you’re paying for in many applications.

By choosing standard-grade coils, you can achieve the necessary strength and durability without the extra cost of custom features.

Cost Analysis: Standard vs. Premium

| Property | Standard GI Sheet Coil | Premium GI Sheet Coil |

|---|---|---|

| Coating Thickness | 30-40 microns | 60-80 microns |

| Corrosion Resistance | Good | Excellent |

| Cost | Lower | Higher |

| Applications | General construction | Harsh environments |

As seen in the table, standard GI sheet galvanized steel coils are sufficient for general construction, offering a good balance of cost and corrosion resistance.

Secret 3: Plan for Efficient Use of Material

Minimize Wastage

Efficiently using GI sheet galvanized steel coils can save both material and labor costs. By carefully planning the cutting and shaping process, you can minimize waste. Ordering coils with the correct dimensions for your project can reduce the need for excess cutting and make your material usage more efficient.

Here are a few tips to optimize material usage:

-

Precise measurements: Ensure you know the exact dimensions needed before ordering.

-

Strategic cutting: Use optimized cutting plans to minimize scrap material.

-

Reuse scrap: Smaller scrap pieces can often be repurposed for smaller components.

Secret 4: Negotiate Better Pricing with Suppliers

The Power of Negotiation

For companies purchasing GI sheet galvanized steel coils regularly, building a good relationship with suppliers can result in more favorable pricing. Many suppliers offer discounts for loyal customers or for larger, long-term contracts.

-

Tip: Ask for price breaks for repeat business or long-term agreements to lock in lower rates for ongoing projects.

In addition, consider negotiating payment terms or delivery schedules to make the purchase even more cost-effective.

Secret 5: Choose the Right Supplier

Choosing a Reliable Supplier

The supplier you choose for GI sheet galvanized steel coils plays a major role in determining the overall cost and quality of your material. Suppliers who offer better logistical solutions, quality certifications, and reliable customer service can save you money in the long run by reducing delays and material defects.

Look for suppliers who offer:

-

Competitive pricing: Ensure you are getting a fair price for the quality of the product.

-

Quality certifications: Verify that the supplier’s products meet industry standards.

-

Timely delivery: Choose suppliers who can meet your project deadlines.

Comparing Suppliers: Cost vs. Service

Here’s a comparison between two hypothetical suppliers:

| Supplier Name | Price per Coil | Delivery Time | Customer Service | Quality Certification |

|---|---|---|---|---|

| Supplier A | $120 | 7 days | Excellent | ISO 9001 |

| Supplier B | $115 | 14 days | Good | None |

Analysis:

-

Supplier A offers slightly higher prices but faster delivery and better customer service. This could save time and money in the long run by avoiding delays.

-

Supplier B offers a lower price but longer delivery and no quality certification, which could lead to potential issues with material consistency.

Common Misconceptions About GI Sheet Galvanized Steel Coils

⚠️ Misconception 1: “Thicker galvanized sheets always provide better corrosion resistance.”

Fact: While thicker coatings offer higher corrosion resistance, the performance of GI sheet galvanized steel coils is more reliant on the quality of the galvanizing process than the thickness alone.

⚠️ Misconception 2: “Galvanized steel coils are always expensive.”

Fact: By opting for standard specifications and purchasing in bulk, you can significantly reduce costs without sacrificing performance.

Conclusion: Maximizing Savings on GI Sheet Galvanized Steel Coils

Purchasing GI sheet galvanized steel coils doesn’t have to be costly. By following these five cost-saving secrets—purchasing in bulk, opting for standard specifications, minimizing material waste, negotiating better prices, and choosing the right supplier—you can significantly reduce material costs while ensuring your projects are completed on time and to a high standard.

Practical Checklist for Sourcing GI Sheet Galvanized Steel Coils

-

Assess project needs: Determine the necessary material specifications and gauge.

-

Purchase in bulk for cost savings on larger projects.

-

Choose standard-grade materials unless premium performance is required.

-

Plan for efficient material usage to reduce waste.

-

Negotiate with suppliers for better pricing and delivery terms.

For high-quality GI sheet galvanized steel coils at competitive prices, contact Shanxi Luokaiwei Steel Company:

-

Email: [email protected]

-

WhatsApp: +86 18912200505