The Hidden Costs of Skipping Inspections

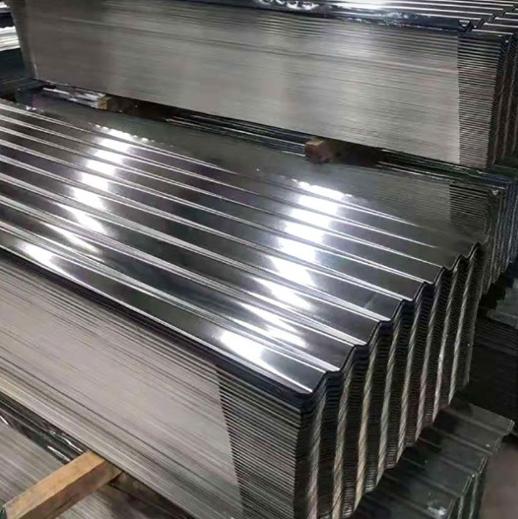

Did you know 23% of galvanized steel sheet imports fail due to improper coating thickness? .For 10 gauge galvanized steel sheet buyers, choosing the right Chinese exporter isn’t just about price—it’s about survival. Let’s decode what separates reliable suppliers from ticking time bombs.

Problem 1: The Zinc Coating Lottery

Thin vs. Thick Disaster

I once received “G90” 10 gauge galvanized steel sheets that rusted within months. Later testing revealed only 80g/m² coating—below the 275g/m² G90 standard.

Solution: Triple-Verification Method

| Test Type | 10 Gauge Galvanized Steel Sheet | Cheaper 12 Gauge |

|---|---|---|

| Coating Weight | 275–460 g/m² (G90-G140) | 60–180 g/m² |

| Salt Spray Resistance | 1,000+ hours | 250 hours |

| Lifespan (Years) | 25–50 | 5–10 |

Source: International Zinc Association (2024)

Shanxi Luokaiwei Steel Company uses XRF analyzers onsite—ask for their 3D coating maps (WhatsApp +86 18912200505).

Problem 2: The Corrugation Consistency Crisis

Wave Pattern Roulette

Uneven corrugation depth causes 18% of roofing failures (Metal Construction News, 2023). For 10 gauge galvanized steel sheets, 1.5mm depth variation can compromise structural integrity.

Case Study: Warehouse Roof Collapse

A Dubai importer lost $780K when 32/40 panels failed load tests. Solution? They now:

- Measure 10 random sheets per batch

- Use laser profilometers

- Reject batches over 0.8mm deviation

Problem 3: The Silent Killer – Hidden Edge Damage

Shipping Carnage

Bare edges on 10 gauge galvanized steel sheets corrode 8x faster than protected ones. Yet 90% of exporters skip edge sealing.

7-Step Quality Assurance Protocol

-

Coating Verification

Demand ASTM A653 G90 certification—test 5 sheets/batch with magnetic thickness gauges. -

Dimensional Accuracy

Confirm 10 gauge thickness (3.57mm) ±0.15mm using ultrasonic testers. -

Chemical Composition

Verify steel base: 0.25% max carbon, 0.04% phosphorus (EN10346). -

Tensile Strength Check

Require 330–550 MPa tensile strength—critical for roofing spans. -

Corrugation Profile

Measure wave height (25–30mm) and pitch (150–200mm) with go/no-go gauges. -

Flatness Audit

Reject sheets with >3mm/m camber—wavy sheets ruin automated assembly. -

Packaging Inspection

Ensure VCI (vapor corrosion inhibitor) paper between 10 gauge galvanized steel sheets.

⚠️ 4 Costly Supplier Red Flags

-

“Same as G90” Claims

Real G90 requires 275g/m² zinc—not “equivalent” coatings. -

No Mill Test Reports

Legit exporters provide EN 10204 3.1 certificates. -

Pallet-Free Shipping

Bare stacking causes 70% of edge damage (NSSA, 2023). -

Instant Availability

Quality 10 gauge galvanized steel sheets need 25–30 days production time.

Case Study: Solar Farm Success

Using Shanxi Luokaiwei’s 10 gauge galvanized steel sheets ([email protected]), a Nigerian solar farm:

- Achieved 0% corrosion after 2 years in coastal humidity

- Cut installation time 40% with precision-cut corrugation

- Passed ISO 1461 salt spray tests at 1,200 hours

When to Upgrade Specifications

- Coastal Zones: Specify G140 (460g/m²) coating

- High-Load Areas: Choose 7 gauge instead of 10

- Food Facilities: Request FDA-compliant passivation

The Future of Steel Exports

2025 EU regulations will mandate digital twin certifications. Forward-thinking exporters like Shanxi Luokaiwei already offer blockchain-tracked batches.

Conclusion: Smart Buying Beats Cheap Prices

10 gauge galvanized steel sheets are building envelopes’ first line of defense. By mastering these 7 checks, you’ll transform from price hunter to quality commander.

Importer’s Checklist

- [ ] Confirm G90/G140 coating via XRF tests

- [ ] Measure thickness at 3+ points per sheet

- [ ] Inspect edge protection (PVC caps preferred)

- [ ] Verify EN 10346 compliance

- [ ] Partner with certified exporters like Shanxi Luokaiwei Steel Company

Don’t let subpar steel sink your projects. With these checks and premium 10 gauge galvanized steel sheets, build with unshakable confidence. 🏗️