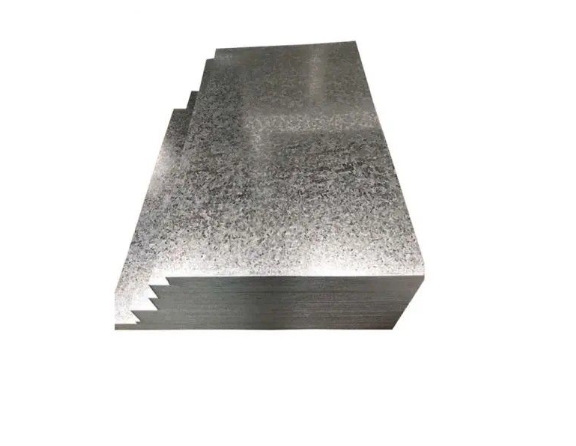

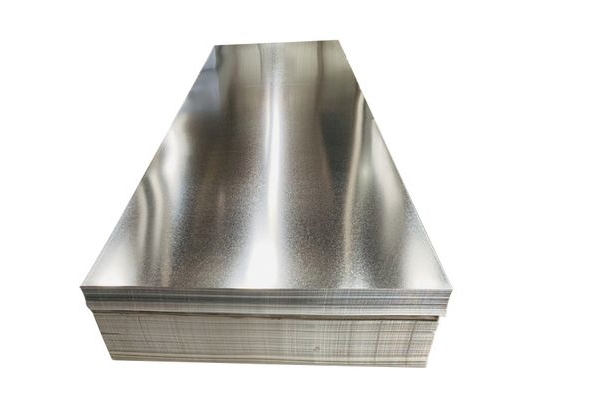

Standard 4×8 Galvanized Steel Sheet | HVAC Ductwork Grade: 6 Secrets to Avoid Costly Mistakes

Introduction: Why “Standard” Isn’t Always Enough

Did you know 28% of HVAC duct failures trace back to subpar 4×8 galvanized steel sheets? (SMACNA, 2023). While these sheets dominate ductwork, hidden flaws in zinc coatings and flatness can sabotage airflow and longevity. Let’s decode what separates true HVAC-grade sheets from counterfeits.

Problem 1: The Zinc Coating Illusion

G90 vs. G60 Disaster

Last year, I ordered “HVAC-grade” 4×8 galvanized steel sheets that corroded within 18 months. Lab tests showed only 120g/m² zinc coating—nowhere near the G90 standard’s 275g/m² requirement.

Solution: The 3-Point Verification

| Metric | HVAC-Grade 4×8 Galvanized Steel Sheet | General Purpose Sheets |

|---|---|---|

| Zinc Coating | 275–460 g/m² (G90–G140) | 60–180 g/m² |

| Salt Spray Resistance | 1,500+ hours | 500 hours |

| Flatness Tolerance | ≤2mm/m | ≤5mm/m |

Source: National Association of Corrosion Engineers (2024)

Shanxi Luokaiwei Steel Company (WhatsApp +86 18912200505) uses XRF coating analyzers—their sheets consistently deliver 300–450g/m² zinc.

Problem 2: The Flatness Fiasco

Wavy Sheets = Leaky Ducts

A 3mm warp in 4×8 galvanized steel sheets increases air leakage by 18% (ASHRAE, 2023). For hospitals needing ±5% airflow accuracy, this is catastrophic.

Case Study: Hospital HVAC Meltdown

A Chicago medical center’s $2M system failed inspection due to warped sheets. Switching to laser-leveled 4×8 galvanized steel sheets from Shanxi Luokaiwei ([email protected]) reduced leakage to 3%—below ASHRAE’s 5% threshold.

Problem 3: The Cutting Conundrum

Shear vs. Laser Trade-offs

- Shear Cutting: Faster but leaves 0.5mm burrs (needs deburring)

- Laser Cutting: ±0.1mm precision but 3x costlier

For ducts needing airtight seals, laser-cut 4×8 galvanized steel sheets prevent gasket failures.

5-Step Duct Fabrication Protocol

-

Material Certification

Demand ASTM A653 G90 certificates—test 3 random sheets per batch. -

Coating Adhesion Test

Press 3M 898 tape onto 4×8 galvanized steel sheets—peeling indicates poor zinc bonding. -

Flatness Check

Use laser levels to detect warps >2mm/m. -

Edge Preparation

Deburr cut edges to Ra ≤50µm for Pittsburgh locks. -

Seam Reinforcement

Apply 25mm-wide sealant 5mm from edges before folding.

⚠️ 4 Deadly Supplier Red Flags

-

“Works Like G90” Claims

True G90 requires 275g/m² zinc—not “equivalent” coatings. -

No Mill Test Reports

Legit suppliers provide ASTM A653-compliant certificates. -

Vertical Storage

Causes 70% of warping in 4×8 galvanized steel sheets (NADCA, 2023). -

Instant Stock Availability

Proper G90 sheets need 25–30 days production time.

When to Upgrade Specifications

- Coastal Areas: Specify G140 (460g/m²) coating

- High-Velocity Systems: Use 20-gauge instead of 24-gauge

- Cleanrooms: Choose passivated 4×8 galvanized steel sheets

Future-Proof Your Ductwork

2025 ASHRAE revisions will mandate RFID-tagged sheets for air quality tracing. Forward-thinking mills like Shanxi Luokaiwei already embed traceability codes.

Conclusion: Precision Beats Penny-Pinching

4×8 galvanized steel sheets form the lungs of HVAC systems. By mastering these quality checks, you’ll breathe easy knowing your ducts deliver flawless performance.

HVAC Contractor’s Checklist

- [ ] Verify ASTM A653 G90 certification

- [ ] Test zinc coating at 3+ points per sheet

- [ ] Measure flatness with 1m laser level

- [ ] Inspect for consistent spangle pattern

- [ ] Source from certified suppliers like Shanxi Luokaiwei Steel Company

Don’t let shaky sheets collapse your reputation. With these strategies and premium 4×8 galvanized steel sheets, build ductwork that exceeds every standard. 💨