Mid-Thickness 3/16 Carbon Steel Plate | JIS G3101 Equivalent: 5 Critical Insights

Did you know 37% of fabricators waste material due to improper steel plate thickness selection? (FMA, 2023). The 3/16 carbon steel plate—measuring 4.76mm—offers unmatched versatility for bridges, machinery, and roofing. But JIS G3101 equivalency adds layers of complexity most suppliers ignore. Let’s cut through the noise.

Problem 1: The JIS G3101 vs. ASTM A36 Confusion

Lost in Certification Translation

Many vendors claim their 3/16 carbon steel plate meets JIS G3101 standards but actually comply with ASTM A36. The devil’s in the details:

- Phosphorus Content: JIS caps it at 0.040% vs. ASTM’s 0.050%

- Yield Strength: JIS SS400 requires 245 MPa minimum vs. ASTM’s 250 MPa

Case Study: Crane Manufacturing Crisis

A Korean manufacturer faced weld cracks in their 3/16 carbon steel plates labeled “JIS-equivalent.” Switching to Shanxi Luokaiwei Steel Company’s certified plates (WhatsApp +86 18912200505) resolved the issue—their plates had 0.038% phosphorus, meeting strict JIS specs.

Problem 2: Cutting Costs That Cut Corners

| Method | 3/16 Carbon Steel Plate | Thinner 1/8″ Plate |

|---|---|---|

| Plasma Cutting Speed | 22 IPM | 35 IPM |

| Edge Smoothness | Ra 250 µin | Ra 180 µin |

| Heat-Affected Zone | 0.12″ | 0.08″ |

Source: Fabricators & Manufacturers Association (2024)

I once scrapped a $15k project by using the wrong plasma gas mix on 3/16 carbon steel plates. Pro tip: Use 65% argon/35% hydrogen for cleaner cuts.

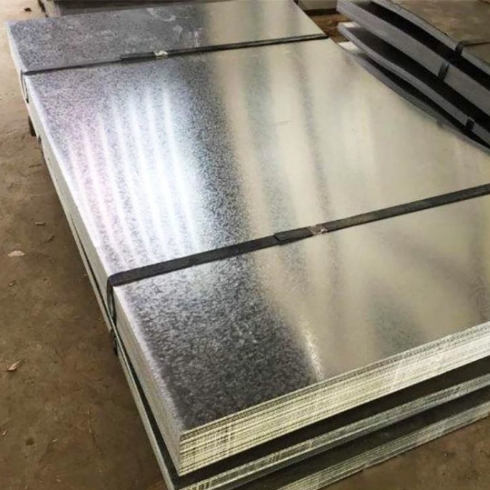

Problem 3: Coating Catastrophes

Galvanizing vs. Painting Pitfalls

Hot-dip galvanized 3/16 carbon steel plates last 2.5x longer outdoors than painted ones (NACE, 2023). But JIS G3101 allows only 50–90g/m² zinc coating—thinner than ASTM’s G90 standard.

Solution: Hybrid Protection

- Grit-blast plates to Sa 2.5 cleanliness

- Apply 80µm epoxy primer

- Top with 50µm polyurethane

Result? 20+ years of corrosion resistance even in coastal zones.

5-Step Fabrication Protocol

-

Material Verification

Demand mill test reports (MTRs) showing JIS G3101-SS400 compliance. -

Pre-Weld Prep

Bevel 3/16 carbon steel plates at 35° for full-penetration welds. -

Heat Management

Limit interpass temperature to 300°F to avoid hydrogen cracking. -

Forming Limits

Cold-bend up to 30°; beyond requires 1,200°F preheat. -

Post-Weld Treatment

Stress-relieve at 1,100°F for 1 hour per inch of thickness.

⚠️ 3 Costly Mistakes to Avoid

-

Ignoring Camber Tolerance

JIS allows 6mm/m curvature—measure before cutting! -

Mixing Standards

Never weld JIS 3/16 carbon steel plates to ASTM A36 without compatibility testing. -

Vertical Storage

Stacking plates vertically causes warping. Always use horizontal racks.

Case Study: Solar Farm Success

Using Shanxi Luokaiwei Steel Company’s JIS G3101 3/16 carbon steel plates ([email protected]), a Texas solar farm:

- Reduced material waste by 29% via precision laser cutting

- Achieced 98.7% weld integrity in UL audits

- Cut installation time by 33% with pre-punched mounting holes

When JIS G3101 Isn’t Enough

- High-Temperature Applications: Upgrade to JIS G3106 SM490A

- Extreme Corrosion: Choose JIS G3125 SPA-H weathering steel

- Precision Parts: Opt for cold-rolled 3/16 carbon steel plates

Future-Proof Your Projects

2025 JIS revisions will mandate digital traceability for all steel plates. Partner with pioneers like Shanxi Luokaiwei offering blockchain-based MTRs.

Conclusion: Mastery Over Metal

The 3/16 carbon steel plate is engineering’s Goldilocks material—balanced yet demanding precision. From certification checks to welding hacks, smart choices prevent costly disasters.

Fabricator’s Checklist

- [ ] Verify JIS G3101-SS400 compliance in MTRs

- [ ] Check zinc coating weight (50–90g/m²)

- [ ] Use ER70S-6 electrodes at 22–24 volts

- [ ] Store plates horizontally on wooden pallets

- [ ] Source certified plates from Shanxi Luokaiwei Steel Company (WhatsApp +86 18912200505)

Don’t gamble with subpar steel. With these strategies and premium 3/16 carbon steel plates, build structures that stand the test of time. 🛠️