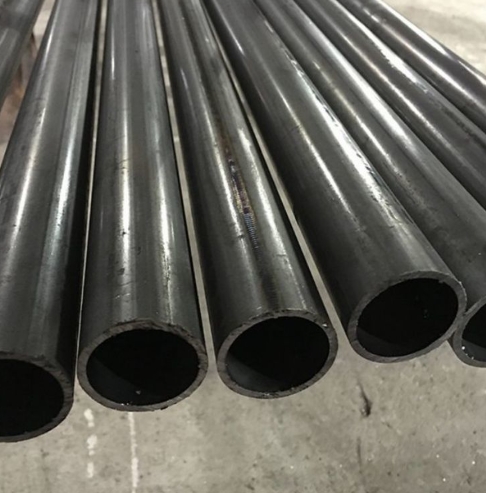

Structural Steel Pipe: High-Strength Tubing for Construction & Engineering Projects.

ASTM A500/A53 Seamless & Welded Pipes (10.3–660mm OD) for Load-Bearing Structures.

Certified to ASTM A500 (cold-formed), EN 10219 (welded), and JIS G3444, these structural pipes support industrial buildings, bridges, and transmission towers with yield strengths up to 552 MPa. Available in SCH 10–XXS wall thicknesses and PSL1/PSL2 grades, they meet ISO 1461 for galvanized corrosion resistance.

Key Features:

- OD Range: 1/8″–26″ (10.3–660mm) with ±1% tolerance.

- Wall Thickness: SCH 10 (1.24mm) to XXS (50mm).

- Certifications: CE Marking, AWS D1.1, and AISC 360.

Technical Specifications

Dimensional Tolerances

| Process | OD Tolerance | WT Tolerance |

|---|---|---|

| Hot-Rolled | ±1% (min ±0.5mm) | +15%/-12.5% |

| Cold-Drawn | ±0.2–1% | ±0.15mm (WT ≤1mm) |

Mechanical Properties (ASTM A106 Grade B)

| Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|

| ≥485 MPa | ≥275 MPa | ≥30% | ≤174 HB |

Material Composition & Grades

Chemical Analysis (ASTM A53 Grade B)

- Carbon: ≤0.30%

- Manganese: ≤1.20%

- Phosphorus: ≤0.05%

- Sulfur: ≤0.06%

Common Grades:

- ASTM A500 Gr. C: 345 MPa yield for stadium frameworks.

- EN 10210 S355J2H: 355 MPa yield for seismic-resistant buildings.

- API 5L X70: 483 MPa yield for hybrid civil-oil infrastructure.

Manufacturing & Surface Protection

- Seamless Pipes: Mandrel piercing + cold drawing (ASTM A53).

- Welded Pipes: High-frequency induction welding (HFIW) for 6–24″ OD.

- Coatings:

- Hot-Dip Galvanized: 85µm zinc layer (ISO 1461).

- Epoxy Paint: RAL 3005 red oxide primer.

Applications & Competitive Advantages

- High-Rise Buildings:

- 508mm OD, 12mm WT A500 Gr. C: Supports 50-ton floor loads.

- Bridge Piling:

- 610mm OD, 20mm WT EN 10219: 120m span river crossings.

- Transmission Towers:

- 168mm OD, 8mm WT JIS G3444: Wind load resistance up to 150 mph.

Advantages vs. Competitors:

- Weldability: Pre-cut beveled ends reduce onsite labor by 40%.

- Custom Lengths: 5.8m/12m fixed or random lengths (DRL/SRL).

Quality Assurance & Testing

- NDT Protocols:

- Ultrasonic Testing: Detects laminations ≥5% WT (ASTM E213).

- Bend Testing: 180° cold bend without cracking (ASTM A370).

- Certifications:

- Mill Test Certificates (EN 10204 3.1).

- Third-party inspection by SGS/BV.

Product Show

Supplier of various types of carbon steel

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.