Is Carbon Fiber Stronger Than Steel? Carbon fiber and steel are both widely recognized for their strength, but their properties differ in key ways. While steel has long been revered for its strength and durability, carbon fiber has risen to prominence due to its impressive strength-to-weight ratio. So, is carbon fiber stronger than steel? The answer is nuanced. Carbon fiber is generally stronger than steel when considering its weight, but steel outperforms carbon fiber in other areas like tensile strength and cost-effectiveness.

1. Introduction to Carbon Fiber and Steel

Both carbon fiber and steel have their own distinct advantages. Steel has been used for centuries, forming the backbone of construction, manufacturing, and transportation. It is known for its reliability, tensile strength, and versatility in various environments.

Carbon fiber, on the other hand, is a relatively newer material, developed in the mid-20th century, which has since revolutionized industries requiring lightweight yet durable materials. Its unique properties make it ideal for high-performance applications such as aerospace, sports equipment, and automotive industries.

2. Strength: A Comparative Analysis

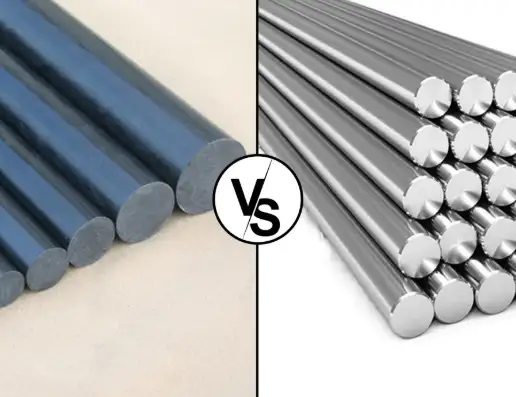

Tensile Strength

Tensile strength refers to the amount of force a material can withstand when being pulled before it breaks. Steel is traditionally stronger in terms of tensile strength, especially in its high-grade forms, such as carbon steel or alloy steel. Steel can typically withstand 250-500 MPa (megapascals) of tensile force, depending on the grade.

On the other hand, carbon fiber can have a tensile strength of 1000-5000 MPa, depending on the specific fiber grade and matrix used. In simple terms, carbon fiber can be much stronger than steel in terms of tensile strength per unit of weight.

Strength-to-Weight Ratio

When we talk about “strength-to-weight ratio,” carbon fiber has a clear advantage. It is significantly lighter than steel and has a comparable or even superior strength when considering the material’s weight. This is why carbon fiber is often used in applications where reducing weight is critical without sacrificing strength.

For example, carbon fiber’s strength-to-weight ratio is approximately 5-7 times higher than that of steel. This makes it an ideal choice for industries like aerospace and automotive, where reducing weight translates into greater fuel efficiency and overall performance.

3. Durability: Resistance to Environmental Factors

While carbon fiber is lightweight and strong, it doesn’t have the same durability in harsh environments as steel. Steel is highly resistant to corrosion when treated with protective coatings, making it suitable for applications in highly corrosive environments like marine and industrial settings.

Carbon fiber, while resistant to corrosion, is more susceptible to damage from extreme temperatures. It can become brittle and lose its strength when exposed to high temperatures (above 200°C) over extended periods, whereas steel can withstand much higher temperatures.

4. Flexibility and Modulus of Elasticity

Another important factor is the material’s ability to bend without breaking. Steel, being a metal, is more flexible and has a higher modulus of elasticity, meaning it can bend or deform under stress without breaking.

Carbon fiber, however, is known for being stiffer and less flexible. It has a low modulus of elasticity, making it less likely to bend. While this rigidity can be an advantage in many applications, it can also make carbon fiber more prone to cracking under extreme stress or impact.

5. Cost: Affordability vs. Performance

Steel remains one of the most affordable materials on the market, which is why it is used extensively in construction, infrastructure, and manufacturing. The cost of steel typically ranges from $700 to $1200 per ton, depending on the grade and market conditions.

Carbon fiber, however, is significantly more expensive, with costs often reaching $10,000 or more per ton for high-performance grades. This higher cost makes carbon fiber impractical for certain large-scale applications where weight and performance are not as critical.

6. Case Study: Use of Carbon Fiber in Aerospace vs. Steel in Construction

In the aerospace industry, carbon fiber is the material of choice due to its low weight and high strength-to-weight ratio. A Boeing 787 Dreamliner, for example, uses 50% composite materials, predominantly carbon fiber, to reduce its weight and improve fuel efficiency. The strength of carbon fiber is critical in such applications, as it must withstand tremendous forces while keeping the overall weight as low as possible.

Conversely, steel remains the dominant material in the construction industry, where its durability, affordability, and strength make it ideal for structural applications like buildings, bridges, and heavy machinery. Steel’s resilience to impact and its ability to support large loads make it a staple in construction.

7. Key Differences in Performance and Application

| Property | Carbon Fiber | Steel |

|---|---|---|

| Tensile Strength | 1000-5000 MPa | 250-500 MPa |

| Strength-to-Weight Ratio | 5-7 times higher than steel | Lower strength-to-weight ratio |

| Durability | Susceptible to high temperatures, not ideal for harsh environments | Extremely durable, resistant to corrosion |

| Flexibility | Stiff, low modulus of elasticity | More flexible, higher modulus of elasticity |

| Cost | Expensive, $10,000+ per ton | Affordable, $700-1200 per ton |

8. FAQs

-

Is carbon fiber stronger than steel in all applications?

No, carbon fiber is stronger than steel in terms of its strength-to-weight ratio, but steel excels in tensile strength and durability in many applications. -

Why is carbon fiber so expensive?

Carbon fiber is expensive due to the complex and energy-intensive manufacturing process, as well as the raw materials required to produce it. -

Can carbon fiber replace steel?

In many applications, especially where weight is a concern, carbon fiber can replace steel. However, in environments where durability and resistance to high temperatures are needed, steel is often preferred. -

Is carbon fiber more brittle than steel?

Yes, carbon fiber is more brittle than steel and can fracture under extreme impact, whereas steel tends to bend without breaking. -

What industries benefit most from carbon fiber?

The aerospace, automotive, and sports industries benefit most from carbon fiber, where strength-to-weight ratio is crucial.

9. Conclusion

In conclusion, carbon fiber is indeed stronger than steel when considering the strength-to-weight ratio. However, steel still holds an edge in tensile strength, durability, and cost-effectiveness, making it more suitable for certain heavy-duty applications. The choice between carbon fiber and steel largely depends on the specific requirements of the application, including factors like weight, strength, flexibility, and cost.