API Spec 5L Steel Pipe Product Overview

API Spec 5L Pipes are thermomechanically controlled processed (TMCP) steel tubes engineered for onshore/offshore hydrocarbon pipelines, CO2 sequestration systems, and hydrogen transport. Available in PSL1 (basic) and PSL2 (advanced) grades like X52 (L360) and X70 (L485), these pipes achieve 290–690 MPa yield strength with ≤0.025% sulfur for sour service compliance (NACE MR0175). Certified to ISO 3183, they replace EN 10208-2 L485MB in projects requiring -30°C Charpy impact toughness and DNV-OS-F101 compliance for subsea installations.

Key Technical Specifications

1. Dimensional & Manufacturing Properties

- Size Range:

- Seamless: 10.3 mm (0.4″) – 1,219 mm (48″) OD | Wall Thickness: 2.0–100 mm

- Welded (SAWL/SAWH): 21.3 mm – 2,600 mm OD | Wall Thickness: 1.65–50 mm

- Tolerances:

- OD: ±0.75% (PSL1), ±0.5% (PSL2)

- Wall Thickness: +12.5%/-8% (PSL1), +10%/-5% (PSL2)

- Surface Coatings:

- 3LPE/3LPP: 2–3 mm anticorrosion layer (ISO 21809)

- FBE Coating: 250–500 µm epoxy (AWWA C213)

2. Mechanical & Chemical Performance

Chemical Composition (PSL2 X70 Example):

| Element | C | Mn | P | S | CEV (IIW) |

|---|---|---|---|---|---|

| Limit | ≤0.12% | ≤1.85% | ≤0.025% | ≤0.015% | ≤0.43% |

Mechanical Properties:

| Grade | Yield (MPa) | Tensile (MPa) | Yield/Tensile Ratio | Charpy Impact (-10°C) | Hardness (HV10) |

|---|---|---|---|---|---|

| X60 | 414–565 | 517–758 | ≤0.93 | ≥40J (PSL2) | ≤245 |

| X70 | 483–621 | 565–758 | ≤0.93 | ≥50J (PSL2) | ≤265 |

| X80 | 552–690 | 621–827 | ≤0.93 | ≥60J (PSL2) | ≤280 |

Pressure Capacity:

| OD (mm) | X70 Wall (mm) | SMYS (psi) | MAOP @ 38°C (bar) | Hydrotest (bar) |

|---|---|---|---|---|

| 762 | 15.9 | 70,000 | 148 | 222 |

| 1,219 | 25.4 | 70,000 | 92 | 138 |

Applications by Industry

| Industry | Use Case | Grade | Key Benefit |

|---|---|---|---|

| Offshore Oil | Deepwater flowlines (1,500m) | X65 PSL2 | DNV-OS-F101 compliance |

| Gas Transmission | Hydrogen blending pipelines (H2 30%) | X52 PSL2 | NACE MR0175 sour service |

| Carbon Capture | CO2 injection lines (100 bar) | X70 PSL2 + 3LPE | ISO 27913 qualifications |

| Refining | High-temperature crude transfer | X60 PSL1 | 758 MPa tensile @ 120°C |

Global Standard Equivalents

| API 5L | EN 10208-2 | DIN 17172 | ISO 3183 |

|---|---|---|---|

| X42 | L 290NB | StE 290.7 | ISO 3183 L290 |

| X65 | L 450NB | StE 450.7 | ISO 3183 L450 |

| X70 | L 485MB | StE 485.7 | ISO 3183 L485M |

Certifications & Compliance

- Welding: API 5L Annex H (HFW/SAW)

- Testing: Hydrostatic (API 5L 9.5), Charpy Impact (ASTM A370), SSC (NACE TM0177)

- Certifications: API Monogram, ISO 9001, PED 2014/68/EU Category II

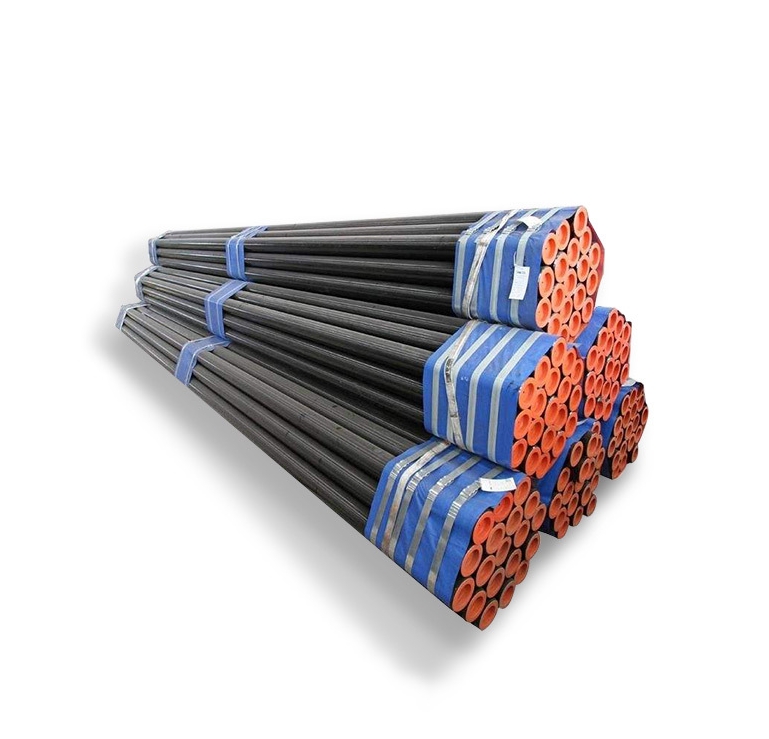

Product Show

G90 Galvanized Sheet supplier

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.