For general piping, structural and industrial use where a balance of strength, availability and cost is required, 3-inch Schedule 40 carbon steel pipe is the most common and practical choice — it offers a 3.500″ outside diameter, nominal 0.216″ wall thickness and an internal bore ≈ 3.068″, is produced to ASME/ANSI dimensional standards and to common material specifications such as ASTM A53/A106; for buyers seeking competitive factory pricing and fast custom service, our Luokaiwei factory in China often delivers superior cost and lead-time compared with many distributors.

Nominal dimensions, weight and quick reference

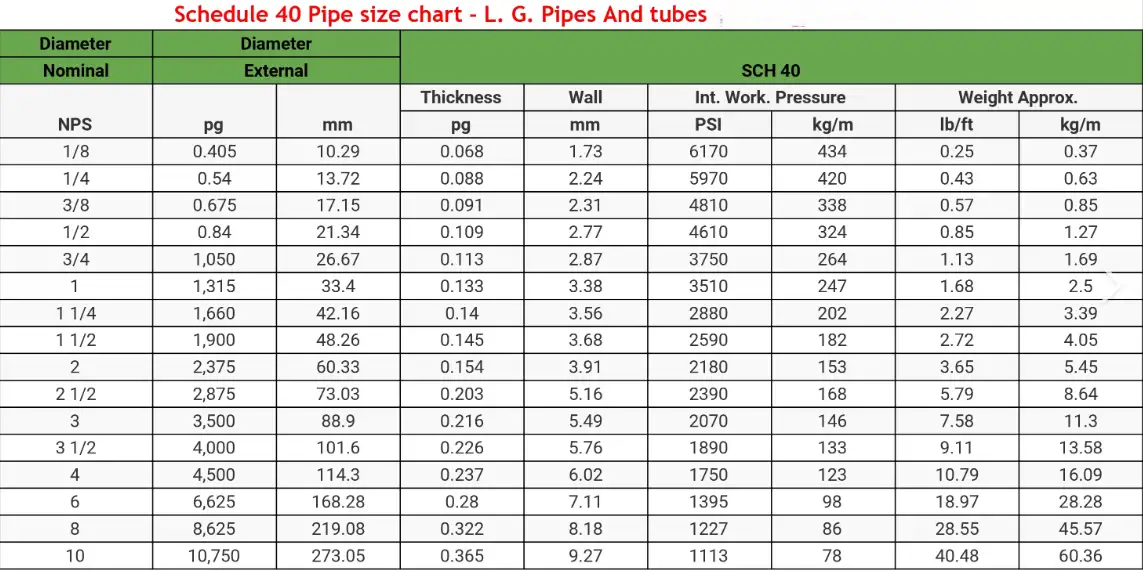

When someone says “3 inch Schedule 40 steel pipe” they are using NPS (nominal pipe size) terminology. The outside diameter (OD) is standardized and does not change with schedule for NPS sizes. For 3″ NPS Schedule 40:

-

Outside diameter (OD): 3.500 in (88.90 mm).

-

Wall thickness (Sch 40): 0.216 in (≈5.49 mm).

-

Approximate internal diameter (ID): 3.068 in (≈77.89 mm) (OD − 2×wall).

-

Typical weight per foot: roughly 7.5–8.0 lb/ft for carbon steel Sch 40 (depends on exact alloy/finish).

Those dimensional numbers come from ASME/ANSI B36.10 (the standard listing OD, schedule and wall thickness) and are the baseline table that manufacturers and purchasers use.

Standards and material grades

Common specifications you will encounter:

-

ASME B36.10 / ANSI B36.10M — dimensional standard for welded and seamless wrought steel pipes (gives OD, wall thickness by schedule). Use this to confirm the OD/wall numbers.

-

ASTM A53 / A53M — “Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless” — commonly used for general purpose mechanical and pressure pipe. Grade A and Grade B are common.

-

ASTM A106 — higher-temperature seamless carbon steel pipe (often specified for higher temperature service).

-

API 5L — if you are buying line pipe for oil/gas transmission, you may see API grades (X42, X52, etc.).

-

ASTM A500 / A53 — sometimes used for structural tubulars (A500) vs pressure pipe (A53). Make sure you request the correct spec for the application.

When requesting a quote, specify: NPS 3, Sch 40, material standard (e.g., ASTM A53 Gr B or A106 Gr B), end finish (plain/ bevel / threaded), length, testing (hydrostatic, UT/RT if required), and coating (black/galvanized/paint/epoxy). Totten/Wheatland catalogues and mill submittal sheets are useful vendor references for the A53 family and testing requirements.

Manufacturing methods and implications

You will see three general routes:

-

Seamless (SMLS) — drawn from a solid billet and considered better for high-temperature or high-pressure applications. Typical for A106 seamless pipe.

-

ERW / Electric-Resistance-Welded — widely used for lower-cost Sch 40 pipe; good dimensional control, economical for long lengths.

-

Furnace butt-welded / continuous welded — another welded route specified under ASTM A53 Type F/E.

Implications: seamless pipes often command a premium, and have different elongation/yield values. For most water, compressed air, structural risers and common plant piping Sch40 ERW or A53 welded is fully acceptable and widely used; for critical high-temperature or sour/pressure service ask for seamless A106 or API 5L with appropriate NDT and certification.

Mechanical properties (typical ranges)

Mechanical numbers depend on the standard and grade:

-

ASTM A53 Grade B (typical): minimum tensile ≈ 60 ksi (≈415 MPa), yield ≈ 35 ksi (≈240 MPa) (consult spec for exact numbers and acceptance tests).

-

A106 Grade B seamless will show similar or slightly higher mechanicals plus better high-temperature performance.

We always recommend requesting the mill test certificate (MTC / EN 10204 3.1) to confirm chemical composition and mechanical test results for each batch.

Corrosion protection and finishes

Common finishes and why they matter:

-

Black (plain) steel — common for structural and many plant applications; economical but rusts if exposed.

-

Hot-dip galvanised (zinc coating) — widely specified for outdoor, potable water mains and where abrasive or wet environments exist. ASTM A53 can be supplied with hot-dip galvanizing.

-

Epoxy/Polyurethane coatings — for buried or marine applications.

-

Threaded and coupled with protective coating — for plumbing and gas where fittings are joined.

Ask for coating thicknesses, adhesion test results and whether surface prep (e.g., sandblast) was performed before coating.

Common applications

We typically see 3″ Sch 40 used for:

-

Plant process piping (water, steam lines at moderate temp/pressure when specified).

-

Structural columns and handrail — where standard pipe sizes are convenient.

-

Hydraulic conveyance in construction, irrigation mains, compressed air headers.

-

Commercial plumbing and small industrial headers.

If you need pressure/vacuum performance at extreme temperatures or service in corrosive environments, specify the correct pipe grade and additional testing (RT/UT, hardness, impact tests).

Pressure ratings and how to think about allowable stress

Schedules are not direct pressure ratings — they give wall thickness which affects allowable stress. For any pressure application you must:

-

Use the appropriate material allowable stress (depending on grade and temperature),

-

Apply hoop stress formula (thin-wall approximate): σ_h = p·D / (2·t) and solve for p = 2·t·σ_allow / D,

-

Apply safety factors and code rules (ASME B31.3, ASME B31.1, or other piping codes) for allowable working pressure (AWP).

We can provide worked examples for a specific grade and temperature if you give us the design temperature and fluid — we avoid guesswork here because allowable stress drops markedly with temperature and depends on material grade.

Joining, fittings and threads

Standard fitting practices:

-

Butt welding for permanent, full-penetration connections.

-

Socket welds for smaller diameters and high-integrity joints (less common at 3″).

-

Threaded (NPT) — frequently used for black pipe in plumbing and gas; remember that schedule walls must leave enough thread engagement. For Sch 40, threads are commonly used but avoid for high-pressure critical piping.

-

Flanged connections — use matching pressure class flanges (ANSI/ASME B16.5 or B16.47) and confirm bore/face type.

When you buy pipe for threading, specify whether you want plain-end, beveled end, or thread-prepared end.

Inspection, testing and marking

Minimum tests we insist on as buyers for pressure or safety-sensitive work:

-

Visual and dimensional inspection against ASME B36.10.

-

Hydrostatic testing (ASTM A53 minimums reference pressure/time for small sizes — see spec).

-

NDT (RT/UT) — required on welded seams for many critical services.

-

MTC / chemical and mechanical test certificates (EN 10204 3.1 or equivalent).

-

Marking: mill name, standard (e.g., ASTM A53), size/schedule, heat or batch number.

Always require traceability back to the heat number for projects that demand certificated materials.

Global price snapshot and purchasing notes

Prices fluctuate with steel raw material markets, transport, and order quantity. Below we summarize indicative retail and mill prices from representative vendor pages (these were sampled from commercial vendor listings and should be treated as guides; please request actual quotes for firm pricing). Sources for the sample prices are cited alongside each region.

| Region | Indicative price (retail, per foot / per meter) | Notes & source |

|---|---|---|

| USA (retail/cut lengths) | USD $20 – $90 / ft (typical structural or ERW: ≈ $20–$35/ft; tested seamless/A106 or cut-to-length specialty: up to $80–$100/ft). | Examples: OnlineMetals US pricing (3″ Sched 40 structural ~ $26/ft) and DMSteel listing showing multi-length pack prices. |

| China (mill export / FOB) | USD $500 – $800 / ton → approx USD $0.8 – $1.8 / ft (bulk/ton pricing; per-piece retail will be higher after cutting, coating, and shipping). | Chinese factory listings and Alibaba (mill/ton quotes). Prices vary by order quantity & coating. |

| India (domestic mill) | INR ~ 1,800 – 3,200 / m (approx USD $8 – $14 / ft) depending on grade and seamless vs welded. | Indian mill price lists and local distributors show Schedule 40 ranges for 3″ sizes. |

| Europe (distributor) | EUR €25 – €80 / ft (retail/distributor dependent; seamless and tested pipe at high end). | European distributors and steel service centers price by grade and certificate requirements. (Representative distributor pricing). |

| Middle East / Brazil | Prices follow regional mill cost + import duty; expect similar to India/China + logistics. | Local distributor quotes vary widely — request local bids. |

Important buying tips we follow:

-

Small single pieces: distributors & cut-to-length suppliers charge a premium per piece; expect higher $/ft. (See DMSteel and OnlineMetals examples).

-

Bulk orders (tons): factory FOB prices from China give best $/ton; add inspection, freight, import duty and local handling.

-

Specify testing & MTC up front — that is what drives mill selection and price.

-

Check whether price is per linear foot, per meter, or per ton — sellers sometimes quote inconsistent units.

Why choose Luokaiwei for 3″ Sch 40 pipe

We are Luokaiwei, a Chinese mill/manufacturer and global supplier. Here’s how we differentiate:

-

Factory direct pricing (100% factory price) — our overhead is lower than reseller/distributor margins; for bulk orders we can quote FOB/EXW mill pricing.

-

Fast delivery for stocked items — we maintain inventory of standard NPS Sch40 lengths; cut-to-length service is available.

-

Customization — we offer beveling, threading, special coatings (galvanized, epoxy), and custom testing packages (RT/UT/hydrostatic) on request.

-

Quality control — full batch traceability, mill test certificates (EN 10204 Type 3.1 / equivalent), and inspection reports.

-

Global shipping experience — we handle export documentation, packing, and can arrange CIF/DDP to many markets.

If you need a formal quote we will ask for: quantity (pcs/tons), standard (A53/A106/API5L), length, coating, and testing required.

Buyer’s checklist

When you prepare a purchase order, make sure it contains:

-

Item description: NPS 3, Schedule 40, steel pipe, [ASTM A53 Gr B or alternative].

-

Quantity: pieces and total length or weight (meters/tons).

-

Length: standard mill length or specific cut lengths.

-

End finish: plain, beveled to ASME B16.25, or threaded.

-

Coating / finish: black, hot-dip galvanised (specify ASTM for coating).

-

Testing: hydrostatic test, UT/RT, PMI (if required), impact tests (if low-temp).

-

MTC / certificate standard: EN 10204 3.1 / 2.2 etc.

-

Packing & marking: by heat number and buyer PO number.

-

Delivery terms: EXW/FOB/CIF and expected lead time.

-

Price & payment terms: unit price (with units), currency, payment schedule.

Failing to include one of these items is commonly what delays deliveries or causes disputes on acceptance.

Environmental, handling and storage notes

-

Store steel pipe off the ground, on timber/dunnage, and under cover where possible.

-

For galvanized pipe avoid contact with concrete that can leach lime and damage coating; patch repair is available for scratched coating.

-

For potable water, verify coating & internal cleanliness; vendors often flush and cap ends for shipping.

Frequently asked questions

Q1 — What is the exact inside diameter of 3″ Schedule 40 pipe?

A: Nominally ≈ 3.068 in (77.9 mm). You compute it as OD (3.500 in) minus two times the wall (0.216 in). Confirm with vendor’s dimensional table.

Q2 — Is Schedule 40 the same as STD (standard)?

A: For many smaller NPS sizes, Schedule 40 is functionally equivalent to “STD” for historical reasons, but do not assume they are identical for every NPS — always check the ASME B36.10 table for the size you need.

Q3 — Can I use Sch 40 for steam service?

A: Possibly — but steam service needs careful attention to temperature limits, material allowable stresses and code compliance (ASME B31.1 or B31.3). For steam at elevated temperatures choose materials and schedules validated for that service and request proper testing and MTCs.

Q4 — Is seamless pipe always better than welded?

A: Not always. Seamless is preferred for high temperature or critical pressure service. For general mechanical, irrigation and structural uses wrought welded and ERW Sch 40 pipe is common and cost-effective. The correct choice depends on application, code, and cost.

Q5 — How much does 3″ Sch 40 pipe weigh?

A: Roughly 7.5–8.0 lb/ft depending on exact wall and material. Dealer cut-to-length listings show weight and price per length in their product tables.

Final recommendations

-

For commercial, structural, or general plant use: specify 3″ NPS Sch 40, ASTM A53 Gr B (or A500 for structural) with plain ends unless welding is needed.

-

For high temperature or critical piping: prefer seamless A106 and require full NDE and MTC.

-

For bulk procurement: get FOB mill quotes from Chinese producers like Luokaiwei (we can support inspection), and compare with local distributor retail pricing — often the all-in landed cost from the factory is competitive for large orders.

If you want, we will prepare: (a) a formal specification template you can paste into a PO, and (b) a firm Luokaiwei quotation based on quantity, finish and required tests. Tell us quantity, finish and destination port and we will quote.