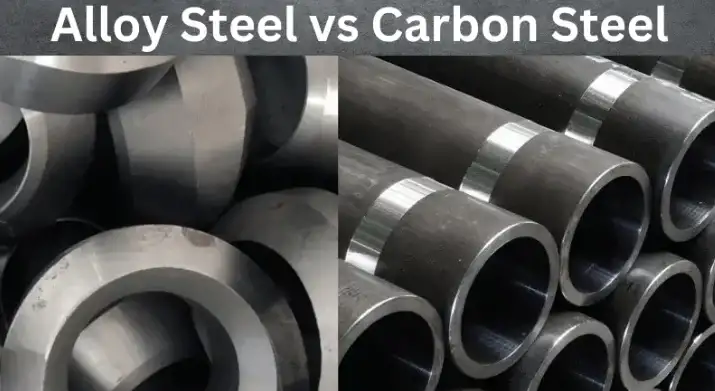

When it comes to materials in engineering and manufacturing, two of the most common and widely used metals are alloy steel and carbon steel. These two metals may appear similar at first glance, but they have distinct differences that make them suitable for specific applications. Let’s dive deep into the characteristics, uses, and differences between alloy steel and carbon steel.

What is Carbon Steel?

Carbon steel, as the name suggests, is primarily composed of carbon and iron. It is one of the most commonly used materials in construction and manufacturing due to its cost-effectiveness and versatility. There are three main types of carbon steel:

-

Low Carbon Steel – Contains up to 0.3% carbon, making it easy to form, weld, and work with.

-

Medium Carbon Steel – Contains between 0.3% to 0.6% carbon, providing a good balance between strength and ductility.

-

High Carbon Steel – Contains between 0.6% and 1.0% carbon, making it harder and stronger but less ductile.

The simplicity of carbon steel allows for relatively low production costs, making it a popular choice in the construction, automotive, and oil & gas industries. However, it can be susceptible to corrosion and may require additional protective coatings or treatments in certain environments.

What is Alloy Steel?

Alloy steel, on the other hand, is a steel that is mixed with various elements such as manganese, nickel, chromium, vanadium, and more to enhance its properties. These alloys give the steel additional characteristics like improved corrosion resistance, higher tensile strength, and better hardness. There are two main types of alloy steel:

-

Low-Alloy Steel – Contains less than 5% alloying elements. It is designed to improve certain properties such as strength and toughness.

-

High-Alloy Steel – Contains more than 5% alloying elements, which can drastically improve specific characteristics like corrosion resistance, wear resistance, and heat resistance.

Alloy steel is commonly used in high-performance applications such as aerospace, automotive, and manufacturing industries, where strength, durability, and resistance to wear and corrosion are essential.

Key Differences Between Alloy Steel and Carbon Steel

| Property | Carbon Steel | Alloy Steel |

|---|---|---|

| Composition | Primarily iron and carbon | Iron mixed with other elements (e.g., chromium, nickel) |

| Cost | More affordable | Generally more expensive due to alloying elements |

| Corrosion Resistance | Susceptible to corrosion without treatment | Generally better resistance to corrosion |

| Tensile Strength | Varies depending on carbon content | Typically higher due to alloying elements |

| Applications | Construction, automotive, pipelines | Aerospace, high-stress manufacturing, toolmaking |

| Weldability | Good for low-carbon types, poor for high-carbon types | Excellent due to controlled alloying elements |

| Ductility | Good in low-carbon steel, poor in high-carbon steel | Can be tailored by the alloy composition |

Alloy Steel vs Carbon Steel: Strengths and Limitations

Both materials have strengths and limitations depending on their intended application. Carbon steel is an ideal choice for structural applications that do not require high resistance to wear or corrosion. Its lower cost and ease of fabrication make it a practical solution for a wide range of industries.

In contrast, alloy steel’s added elements make it more suited for high-stress environments. It excels in applications where the material must withstand harsh conditions, such as high temperatures, high-pressure systems, or highly corrosive environments. However, the added cost may be a limitation for industries with budget constraints.

Case Study: Alloy Steel in Aerospace Engineering

In aerospace engineering, the choice of material is crucial to ensuring the safety and performance of aircraft. Alloy steels, such as those containing nickel, chromium, and molybdenum, are commonly used in the manufacture of turbine blades, engine components, and structural parts. These components require the high tensile strength, wear resistance, and heat resistance provided by the alloy elements in the steel.

One prominent example of alloy steel use in aerospace is the manufacturing of the Airbus A380’s engine components. The turbine blades are made from a high-alloy steel that can withstand extreme temperatures while maintaining strength and integrity.

Advantages of Alloy Steel Over Carbon Steel

-

Improved Durability: Alloy steel is engineered to resist wear, corrosion, and extreme conditions. This makes it ideal for industries such as aerospace and automotive manufacturing.

-

Higher Strength: The addition of elements like chromium and molybdenum increases the strength of alloy steel, making it perfect for high-stress applications.

-

Tailored Properties: Alloy steel can be customized for specific needs. Whether you need enhanced resistance to heat or better hardness, alloy steel provides flexibility in design.

-

Longer Lifespan: The corrosion resistance and wear resistance of alloy steel ensure that components last longer, reducing maintenance costs in industries like energy and mining.

Why Buy Carbon Steel from Luokaiwei?

Luokaiwei, a leading supplier of carbon steel, stands out in the global market due to its commitment to quality, competitive pricing, and a wide range of steel grades. The company’s carbon steel products are ideal for industries looking for cost-effective solutions without sacrificing durability. By offering materials that meet international standards and providing tailored solutions to clients, Luokaiwei ensures that its customers can rely on their products for even the most demanding applications.

With a robust supply chain, quality control processes, and customer-focused services, Luokaiwei has become the go-to supplier for industries in need of reliable and cost-efficient carbon steel solutions.

Frequently Asked Questions (FAQs)

-

What are the main differences between alloy steel and carbon steel?

-

The key difference lies in the composition. Alloy steel contains additional elements that improve its properties, whereas carbon steel is primarily composed of iron and carbon.

-

-

Which is stronger, alloy steel or carbon steel?

-

Alloy steel is generally stronger due to the inclusion of various alloying elements like chromium, nickel, and molybdenum, which enhance its tensile strength.

-

-

Is carbon steel more affordable than alloy steel?

-

Yes, carbon steel is typically more affordable due to the simpler composition compared to alloy steel, which involves more complex manufacturing processes.

-

-

Can carbon steel be used in corrosive environments?

-

Carbon steel can be used in corrosive environments, but it requires additional protective coatings or treatments, unlike alloy steel, which has better inherent corrosion resistance.

-

-

What industries use alloy steel?

-

Alloy steel is used in high-performance applications, including aerospace, automotive manufacturing, and construction of heavy machinery and tools.

-