In 2025, Q235 hot-dip galvanized pipe prices are broadly lower in Chinese domestic FOB markets (roughly USD 400–750 / tonne depending on size, zinc weight and quantity) while western markets (US / EU) trade at materially higher levels — roughly USD 900–1,200 / tonne for comparable hot-dip galvanized (HDG) pipe products after local processing, shipping and tariffs. Buyers should expect regional spread driven by raw-material indices (HRC/coil), zinc costs, logistics, and trade measures; for large, repeat projects the most cost-effective route remains buying directly from China manufacturers such as Luokaiwei.

We monitor coil and finished pipe markets weekly. In the first half of 2025 the global hot-dip galvanized coil and pipe complex showed a mixed picture: domestic Chinese HRC/coil prices stayed far below western levels, which keeps Chinese finished-pipe FOB offers competitive for export; meanwhile zinc and regional trade measures (tariffs / anti-dumping) pushed landed prices higher in some importing markets. For buyers this means the headline “Q235 galvanized pipe price” can validly be USD ~400–1,200 / tonne depending on the supply route and specification — a wide, but realistic, spread.

What is Q235 steel

Q235 is a Chinese carbon structural steel grade defined in GB/T 700 (Q235A/B/C/D variants). It is widely used for structural sections, tubes and general fabrication because of its balance of strength, weldability and cost. Internationally the closest equivalents are ASTM A36 (USA) and S235JR (EN/Europe), which is important when matching specifications for international projects. Typical yield strength is in the ~235 MPa class (hence the ‘235’). When we supply Q235 pipe we confirm the GB/T certificate and mechanical test report (MTR) with chemical analysis.

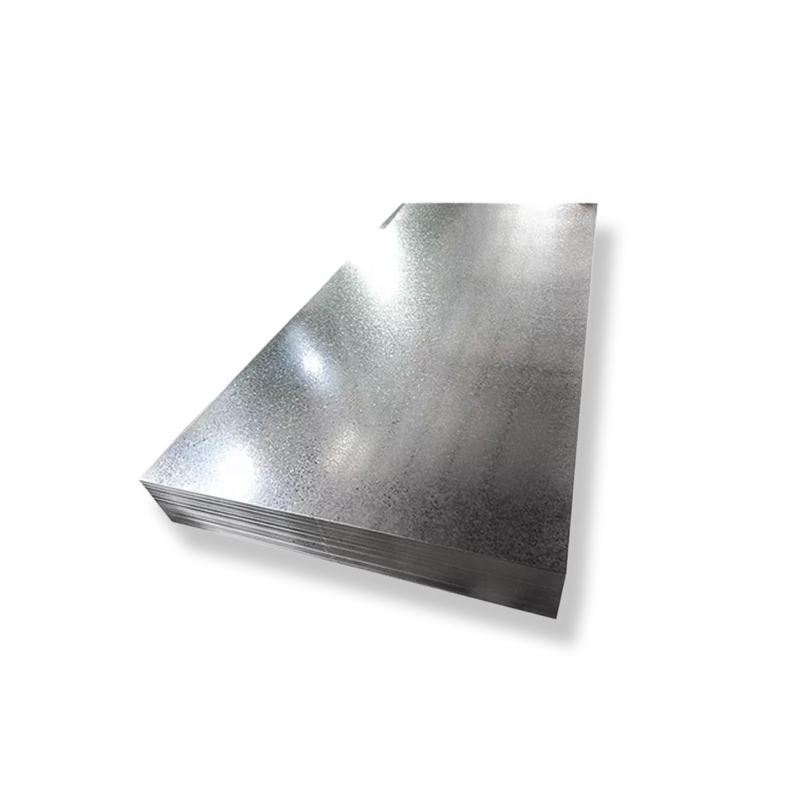

Why galvanize Q235 pipe?

Galvanizing (normally hot-dip galvanizing for pipes) metallurgically bonds zinc to steel and gives sacrificial corrosion protection. For external and buried water / drainage / fencing / structural pipe uses, galvanized Q235 delivers a low-maintenance lifetime far longer than bare carbon steel in most environments. The galvanizing step adds a modest manufacturing cost but reduces painting, maintenance and replacement costs over a pipeline or structure lifecycle — a strong value proposition for infrastructure buyers. For engineered projects we always evaluate expected environment (rural, marine, industrial) to specify zinc weight or duplex systems when needed.

Primary galvanizing methods & standards you should demand

-

Hot-dip galvanizing (HDG) is the dominant method for pipes — the article on HDG gives the basic process and pros/cons.

-

Key standards to reference in contracts: ISO 1461 (EN ISO 1461) and ASTM A123 / A123M — these govern coating thickness, adhesion and test methods for hot-dip galvanized articles and are used worldwide. For pipe produced in China and exported to Europe/US, referencing the appropriate ISO/EN or ASTM standard in the purchase order avoids disputes.

What drives Q235 galvanized pipe price in 2025: the cost components

When we price a finished Q235 HDG pipe the key inputs are:

-

Raw steel cost (coil / billet / HRC) — primary driver; Chinese hot-rolled coil prices have historically been well below western levels (a material price differential that underpins Chinese FOB competitiveness).

-

Zinc metal cost and galvanizing flux / consumables — zinc price movements shift HDG margins but usually less violently than steel. IZA publications and galvanizer guidance explain this link.

-

Processing cost — forming, welding, testing, galvanizing line throughput — thicker walls, special fittings, or high zinc coat weights raise per-ton labor and furnace time.

-

Coating specification (g/m² or microns) — higher coating classes (heavy coatings) increase zinc consumption and time in the kettle. See ISO/ASTM specs.

-

Logistics & freight — ocean freight, container vs bulk, inland trucking. In 2025 freight is a smaller share than in pandemic years but still material for smaller orders.

-

Trade measures & tariffs — anti-dumping or import duties (notably US steel tariffs implemented in 2024–2025) can add a large percent to landed cost. Always run landed-cost math.

We always break prices down for customers so they can see where value or risk lies.

Regional price comparison (practical ranges for Q235 HDG pipe in 2025)

NOTE: the ranges below are indicative, per-ton ranges for finished hot-dip galvanized pipe (not raw coil), intended to help procurement estimates. Prices vary by size, zinc coat, order quantity and destination port. We cite regional market data sources after the table.

| Region / route | Indicative price (USD / tonne) | Notes |

|---|---|---|

| China — domestic FOB (Qingdao / Tianjin) | USD 400 – 750 / t | China factory/FOB offers for Q235 HDG pipe commonly sit here for standard sizes in bulk; small orders higher. |

| India — domestic ex-works | USD 500 – 900 / t (or local Rs/kg conversion) | India producers (Jindal, local mills) offer competitive domestic pricing but product shape/size pricing is common; see local price lists for per-meter rates. |

| Europe — ex-works / ex-warehouse (HDG coil & pipe) | USD 700 – 1,000 / t | Northern / Western Europe ex-works for HDG finished product typically higher — Fastmarkets/Kallanish price levels for HDG coil inform finished pipe costs. |

| USA — domestic finished HDG pipe | USD 900 – 1,200 / t | U.S. HDG/pipe pricing reflects HRC base levels, galvanizer margins and tariffs; spot HDG indexes in 2025 were often ~USD 980–1,100/t. |

| Middle East / MENA — CIF local ports | USD 650 – 1,000 / t | Depends on supplier (China or local), logistics and local standards acceptance; Middle East imports from China remain price-competitive despite freight. |

Citation / justification: regional ranges above are synthesized from steel index reports (SteelBenchmarker, IndustrialTube), Fastmarkets/Freemarkets commentary for Europe, and multiple supplier FOB listings from China/India (Made-in-China / Alibaba / supplier price sheets). These sources show the persistent China vs west delta and current HDG price brackets used above.

How zinc coat weight and process choices affect price and life

Two customers can buy “Q235 galvanized pipe” and receive very different products: zinc coat weight (typically expressed as g/m² or µm) and the galvanizing method determine corrosion resistance and cost.

-

Common coating classes: light, standard, heavy (e.g., 40–80 g/m² up to 275 g/m² or higher on special orders). Heavier coatings add zinc consumption cost (zinc metal priced separately) and more galvanizing time — expect ~5–15% price uplift for standard→heavy coatings depending on thickness. Standards such as ASTM A123 / ISO 1461 detail coating acceptance and testing.

-

Continuous vs batch galvanizing: continuous (strip) galvanizing is used for coil/strip; batch (kettle) galvanizing is typical for fabricated pipes and complex items — batch process flexibility can add handling costs but is necessary for many pipe sizes.

When we quote for customers we always show zinc coat weight options with expected lifecycle (e.g., typical coastal exposure vs inland) so a buyer can compare upfront price vs maintenance savings.

Typical specifications and inspection points buyers must demand

To avoid disputes we include the following in PO and test protocol:

-

Material certificate (MTR) to GB/T 700 Q235 (or equivalent ASTM A36 / EN S235JR) with chemical & mechanical results.

-

Coating spec: state ISO 1461 (or ASTM A123), required minimum g/m² or µm and test frequency.

-

Dimensional tolerance: OD, wall thickness, straightness and length tolerance.

-

Non-destructive tests: visual coating inspection, thickness measurement (magnetic gauge), adhesion checks and spot salt spray tests if specified. See galvanizer guidance on measurement and sampling.

-

Packing and marking: bundles labelled with grade, OD x WT, heat number and PO number.

-

Third-party inspection (if required): SGS / BV / ITS at mill before shipment.

We insist on these to avoid “appearance” disputes — the coating may vary visually but must meet the agreed numeric requirements.

Logistics, lead times and landed cost worked example

Simple landed cost example (very approximate, per tonne):

-

China factory FOB: USD 600 / t (Q235 HDG pipe) — example mid-range FOB.

-

Ocean freight (FOB → EU port): USD 60 – 120 / t (depends on containerization and route)

-

Insurance & inland clearance: USD 20 – 40 / t

-

Import duty / anti-dumping (if any): varies widely — the US 50% tariff announced in 2025 is an example of a major uplift. Check current trade measures.

-

Local transport to site / domestic VAT: variable.

Observation: a low FOB from China can be offset by tariffs or long supply chains; for bulk long-lead projects we recommend contracting multiple partial shipments to balance inventory vs price risk.

How to source: manufacturer vs trader

We regularly advise customers to buy factory-direct for three reasons:

-

Price transparency — you avoid trader margins; we offer 100% factory price advantage on many stock SKUs.

-

Customization — direct factory supply enables custom OD, wall thickness, zinc coat weight and fittings assembly. We support custom cutting, beveling, punching and other services.

-

Quality control — factory acceptance testing (internal QA + third-party inspection) is simpler to coordinate with a single manufacturer.

At Luokaiwei we are a Chinese manufacturer experienced in Q235 steel pipe production and hot-dip galvanizing. We operate stock lines for common sizes to shorten lead time and offer OEM services for project needs. For buyers with urgent requirements our in-stock items can be shipped quickly; for engineered projects we support project documentation, MTRs, and supply chain transparency.

Tender, contracting and price-risk management tips

-

Specify standards precisely (e.g., “Q235B per GB/T 700, HDG per ISO 1461, minimum Zn coating 275 g/m²”) to avoid ambiguity.

-

Fix freight or use CIF if you prefer the supplier to manage shipping risk.

-

Use staged deliveries and price review clauses tied to a reputable steel index if the contract runs over many months.

-

Require acceptance tests at the mill (visual + thickness + MTR).

-

Payment terms: for first orders we recommend 30% deposit, balance after inspection; for trusted repeat customers we offer more flexible terms.

FAQs

Q1 — What is the single best way to reduce per-ton cost on Q235 galvanized pipe?

Buy direct from a trusted factory with confirmed in-stock lines and order in larger bundles; negotiate zinc coat weight appropriate to environment (don’t over-specify) and lock shipping terms. We provide factory pricing and stock delivery to reduce total cost.

Q2 — How much does zinc coating add to cost?

Depends on coat weight: heavier coatings add both metal cost and process time. Expect a small percent uplift (commonly 5–15%) from standard to heavy coating classes; quantify in tender.

Q3 — Are Q235 and A36 interchangeable for galvanized pipe?

They are broadly comparable in mechanical class (Q235 ≈ A36 / S235JR) but your engineering spec should list the exact standard and mechanical limits you require; some projects require traceable MTRs to the listed standard.

Q4 — Will US tariffs make Chinese pipe always more expensive?

Tariffs can materially raise landed cost into the US — in 2025 some US measures increased effective imported steel costs. Tariffs change by policy and product, so always check current measures for the product HS code.

Q5 — How long will galvanized Q235 pipe last?

Service life depends on environment and coat weight. In mild inland conditions standard HDG (per ISO/ASTM values) can last decades; in aggressive marine environments select higher zinc coating or duplex systems (galvanize + paint). We can model expected life vs coat weight per project.

Practical procurement checklist

-

Confirm grade (Q235B etc.) and obtain MTRs

-

Specify galvanizing standard (ISO 1461 or ASTM A123) and minimum g/m²

-

Agree dimensional tolerances and acceptance sampling plan

-

Specify packaging, marking and test documentation (inspection report, mill certificate)

-

Decide incoterm (EXW/FOB/CIF) and include X-ray / third-party inspection if required

Closing recommendation

If your project needs Q235 galvanized pipe in 2025 we recommend obtaining three comparable quotes (factory FOB China, regional producer ex-works, and local supplier with inventory). For large or technical projects contact us at Luokaiwei — we supply factory-direct Q235 HDG pipe, offer customization, stock fast delivery on common sizes, and transparent factory pricing to help you reduce total procurement cost and delivery risk.