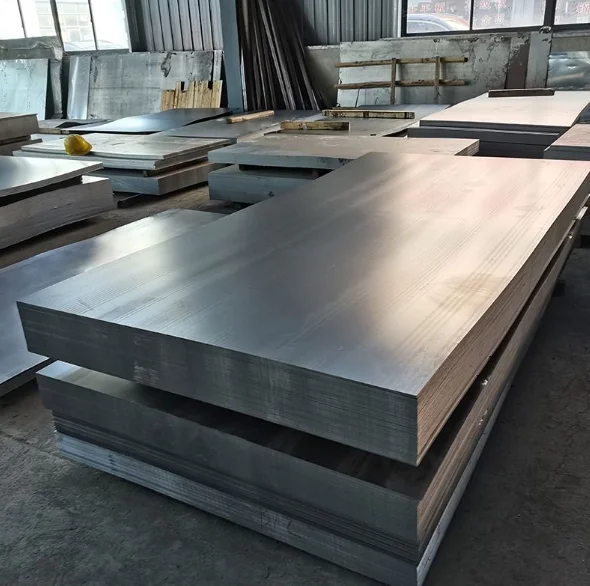

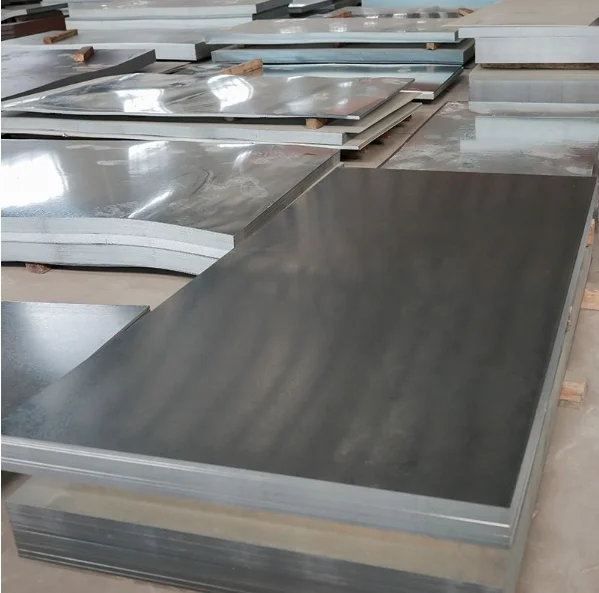

Marine steel plates are specifically designed to meet the rigorous demands of shipbuilding and marine structures. These plates are engineered to withstand the extreme stresses of the sea, offering superior strength, corrosion resistance, and durability, making them the perfect material for ship hulls, offshore platforms, and other marine applications.

Marine/Ship Steel Plates are carbon steel plates designed to provide high strength and resilience, ensuring reliable performance in marine environments. These plates comply with international standards for marine construction and are available in a variety of grades and specifications to suit different applications, such as shipbuilding, offshore structures, and marine equipment.

Key Specifications

Material Grades:

-

A32, A36, A40, AH32, AH36, AH40: Commonly used for ship hulls, decks, and marine platforms.

-

BV Grade A, D, E: For ships and offshore structures requiring higher weldability and toughness.

-

LR Grade A, B, AH36, DH36: Designed for enhanced strength and resistance to marine corrosion.

Mechanical Properties:

-

Yield Strength: 235–355 MPa, depending on grade

-

Tensile Strength: 400–520 MPa

-

Elongation: ≥20% in 200mm

-

Charpy V-notch Impact: ≥27J at -20°C

-

Brinell Hardness: ≤170 HB

Thickness Range:

-

Thickness: 6mm – 100mm

-

Width: Up to 3,000mm

-

Length: Custom lengths available

Key Features and Advantages

-

High Corrosion Resistance:

-

Special coating processes, such as galvanization or primer coating, ensure long-lasting protection against the harsh marine environment.

-

Resistant to saltwater, humidity, and extreme weather conditions, prolonging the lifespan of the structure.

-

-

Excellent Weldability and Fabrication:

-

Marine steel plates are highly weldable, making them ideal for complex structures such as ship hulls, offshore rigs, and marine pipelines.

-

Easy to cut, drill, and shape, which facilitates efficient manufacturing processes.

-

-

Superior Strength:

-

Provides high tensile strength and yield strength, ensuring the safety and integrity of ships and marine platforms during service.

-

Excellent toughness at low temperatures, essential for marine operations in freezing waters.

-

-

Durability:

-

These plates are specifically designed to withstand heavy loads, impacts, and environmental stress, making them ideal for vessels exposed to heavy seas and wind forces.

-

-

Variety of Standards:

-

Complies with international marine standards such as ASTM, ISO, LR, BV, ABS, and DNV, ensuring reliable and consistent quality for shipbuilders and offshore contractors.

-

Applications

-

Shipbuilding: Used in the construction of ships, including cargo ships, tankers, passenger ships, and military vessels.

-

Offshore Platforms: Essential for building oil rigs, floating platforms, and other offshore structures.

-

Marine Engineering: Used for structural components, hulls, decks, and other parts of boats and marine vessels.

-

Marine Equipment: Ideal for equipment exposed to water, such as marine pipelines, docks, and seawalls.

-

Specialty Marine Applications: Including underwater structures and coastal infrastructure that require enhanced resistance to corrosion.

Related Marine Steel Grades

-

Grade A: Standard quality, suitable for general shipbuilding.

-

AH36: High-strength steel for use in offshore structures and ships.

-

DH36: Enhanced version of AH36, offering higher toughness and better performance at low temperatures.

-

EH36: Marine steel plate that offers excellent resistance to corrosion and is ideal for ship structures exposed to rough seas.

Request a Quote Today

For a competitive quote or technical assistance, please contact us at [email protected] or +86 18912200505.

Whether you’re constructing a ship, offshore platform, or marine structure, Shanxi Luokaiwei Steel Company is your trusted partner for premium marine/ship steel plates that meet international standards.