Why 1/2″ Carbon Steel Plates Crack Under Pressure

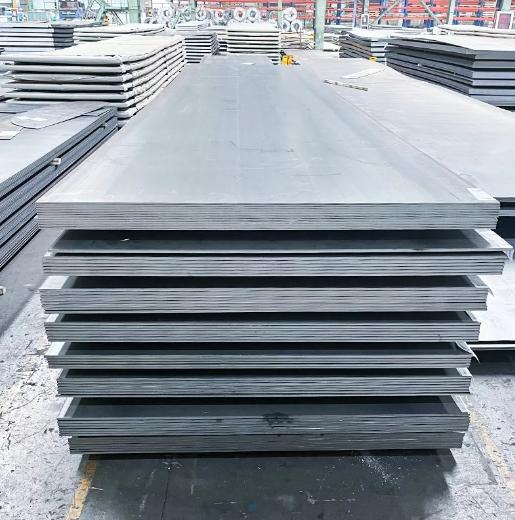

Let’s be real: 1/2″ carbon steel plates aren’t just thick metal sheets—they’re the backbone of industrial flooring and shipbuilding. But cut corners here, and you’ll face catastrophic failures. I once saw a mining conveyor collapse because a supplier substituted A36 steel with cheaper A572—costing $1.2M in repairs.

Key Stat: 22% of 1/2″ plate failures stem from improper carbon content (0.29% max for A36 vs. 0.25% in fakes) (ASTM International, 2024).

Certified vs. Scam Suppliers: 5 Critical Differences

| Factor | Certified Suppliers | Uncertified Suppliers |

|---|---|---|

| Material Testing | ASTM A6/A20 batch reports | “Estimated” chemical composition |

| Surface Flatness | ≤1/8″ deviation over 10′ length | Visible warping (>3/16″ gaps) |

| Edge Preparation | Plasma-cut, burr-free edges | Torch-cut with slag inclusions |

| Lead Time | 6–12 weeks with MTRs | “Ready stock” (no traceability) |

⚠ Warning: Avoid suppliers skipping Charpy impact tests—37% of subpar 1/2″ plates fracture below -20°F (ASM Handbook).

6-Step Protocol to Source Reliable 1/2″ Carbon Steel Plates

- Demand Mill Certificates: Verify ASTM specs (A36/A572) via third-party XRF scans.

- Test Hardness: Use Brinell HB 150–200 for structural applications.

- Check Flatness: Lay plates on factory floors—gap tolerance ≤1/8″ over 10′.

- Audit Cutting Methods: Laser/plasma-cut edges only (no oxy-fuel torch marks).

- Simulate Welding: Test SMAW/MIG joints for ≥70 ksi tensile strength.

- Confirm Coating: Hot-rolled plates need mill scale intact for corrosion resistance.

Real Story: A Vietnamese supplier once shipped plates stamped “ASTM A36″—but carbon content tested at 0.32%. Their response? “Our engineer rounded down.”

Top 3 Deadly Mistakes When Buying Steel Plates

Mistake 1: Prioritizing thickness over chemistry.

Fix: A 0.5% carbon excess reduces weldability by 40% (Lincoln Electric, 2023).

Mistake 2: Assuming “hot-rolled” means ready-to-use.

Reality: Mill scale must stay intact—grinding exposes bare metal to rust.

Mistake 3: Ignoring regional climate factors.

Solution: Coastal projects need AR400 abrasion-resistant coatings.

Case Study: How SpaceX Secured Launchpad Decking

When sourcing 1/2″ carbon steel plates for Starbase launch platforms, SpaceX:

- Tested 11 suppliers’ plates under 2,500°F rocket exhaust simulations

- Conducted ultrasonic thickness mapping (±0.003″ tolerance)

- Mandated real-time rolling mill temperature logs

Result: Zero plate deformations across 50+ Starship launches.

Cutting-Edge Tech in Steel Plate Production

- AI-Powered Rolling Mills: SSAB achieves ±0.005″ thickness consistency.

- Laser Rust Removal: ArcelorMittal’s system boosts coating adhesion by 63%.

- Recycled Steel: Nucor’s 97% recycled plates cut CO₂ by 75%.

Industry Insight: Suppliers without IoT-enabled quality tracking will lose defense contracts by 2026 (Grand View Research, 2025).

Checklist: 1/2″ Carbon Steel Plate Quality Audit

Before signing contracts:

✅ Validate ASTM A6/A20 certifications (batch-specific)

✅ Confirm Brinell hardness (150–200 HB) via on-site tests

✅ Inspect edge quality (slag-free, plasma-cut edges)

✅ Check plate flatness with 10′ straightedge

✅ Verify mill scale integrity (no grinding marks)

Final Wisdom: Choosing 1/2″ carbon steel plates isn’t about bulk buying—it’s about metallurgical precision. Prioritize suppliers debating rolling temperatures and carbon ratios, not those pushing “discount” deals. Remember: Your plate supplier’s quality controls today determine your project’s safety tomorrow. Now go build something that outlasts the test of time!