Galvanized Steel Sheet: Advanced Applications & Technical Specifications

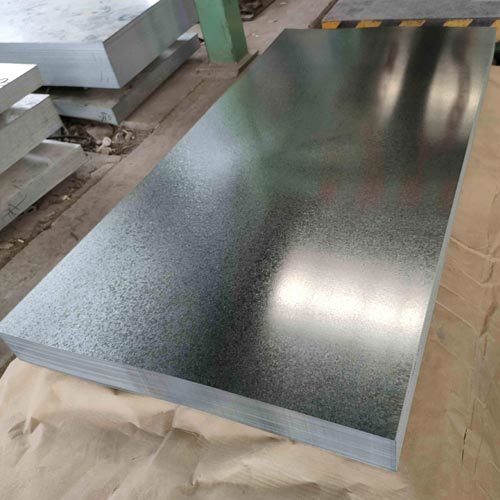

Direct Coating Advantage

Hot-dip galvanized surfaces enable pretreatment-free adhesion of bituminous coatings (e.g., asphalt, coal-tar epoxy) due to:

- Optimal surface roughness: Ra 3-8 μm (ISO 4288)

- Zinc-iron alloy layer porosity: <5% (ASTM B117 salt spray compliance)

Industrial Application Matrix

1. Construction & Structural Engineering

- Roofing/Wall Systems:

- Material: Z275-Z450 HDG sheets (EN 10346)

- Thickness: 0.4-1.5mm with AZ150 coating

- Performance: 40-year lifespan in C4 marine environments

- Acoustic Barriers:

- 80-150mm composite panels with 2.0mm HDG substrate

- Sound reduction: 25-35 dB (ISO 717-1)

2. Automotive Engineering

- Exhaust Systems:

- Grade: HX340LAD+Z (EN 10346)

- Aluminized coating hybrid for 900°C thermal resistance

- Fuel Tanks:

- 1.2-2.0mm EG sheets (SECC, JIS G3302)

- Coating weight: 20/20 g/m² (double-sided)

3. Appliance Manufacturing

| Component | Material Specification | Key Requirement |

|---|---|---|

| Refrigerator Shell | SECC-SD, 0.6mm (JIS G3313) | ERC ≥12mm (deep drawing) |

| Microwave Cavity | HDG ZM310, 1.0mm (ASTM A653) | Non-sparking surface |

| Electrical Cabinets | Galvannealed (GA) 60/60 g/m² | Painted adhesion ≥4B |

4. Agricultural Infrastructure

- Livestock Housing:

- 0.7mm HDG sheets with micro-rib texture (anti-slip Rz=15-25μm)

- Coating: Z600 (600g/m²) for ammonia corrosion resistance

- Grain Storage:

- 2.0-3.0mm structural sections with 85μm Zn-Mg coating

5. Specialized Industrial Equipment

- Heat Exchangers:

- 0.3-0.8mm EG strips (CQ/FS/ED grades)

- Continuous service: -50°C~200°C

- Drying Chambers:

- HDG Z275 with silicone-modified polyester coating

Technical Comparison: HDG vs. EG

| Parameter | Hot-Dip Galvanizing (HDG) | Electrogalvanizing (EG) |

|---|---|---|

| Coating Thickness | 50-150 μm | 5-30 μm |

| Process Speed | 3-8 m/min | 10-30 m/min |

| Edge Protection | Full metallurgical bonding | Limited edge coverage |

| Cost Efficiency | $40-80/ton premium | $15-30/ton premium |

Certification & Compliance

- Construction: EN 10346, ASTM A653 (G90/G120)

- Automotive: ISO 3575, VDA 239-100

- Food Contact: FDA 21 CFR 175.300 compliant grades

Available in coil (0.3-3.0mm) or pre-cut blanks (≤12,000mm length). Custom Zn-Al-Mg coatings (5%Al-3%Mg) available for 3x enhanced corrosion resistance.

Product Parameters

| Product Name | Galvalume Steel Sheet |

| Thickness | 0.12mm-6.00mm |

| Width | 600mm-1500mm |

| Length | 1m-12m, Support Customization |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Thickness of Aluminum Zinc Coating | 30-185g/m² |

| Content of Al-Zn Coating | Al: 55%, Zn: 43.5%, Si: 1.5% |

Chemical Composition

| Al | Zn | Si | Fe | Cu | Cd | Pb | Sn | Ni | Close Cr |

| 55-58 | 41-43 | 1.5-2 | 0.25 | 0.03 | 0.05 | 0.01 | 0.05 | 0.05 | 0.05 |

Mechanical Properties

| Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

| DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD Z/ZM/AM | 220 | 300 | 20 |

| S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD Z/ZM/AM | 280 | 360 | 18 |

| S300GD A/AM | 300 | 380 | 18 |

| S320GD Z/ZM/AM | 320 | 390 | 17 |

| S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD A/AM | 450 | 480 | 15 |

| S550GD Z/ZM/AZ/AM | 550 | 550 | – |

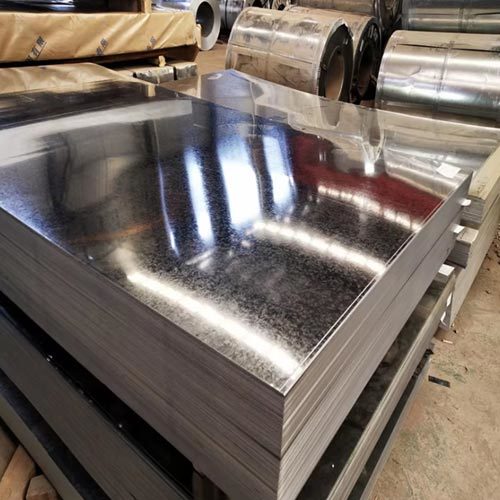

Galvanized Surface Selection

| Type of Coating | Recommended Coating Weight |

| Aluminum-zinc Alloy | 30/40/50/60/75/90/100/150 |

| A: Coating quality50g/㎡,approximately equal to the coating thickness13.3pm | |

| Project | Classification | Symbol |

| Type of Coating | Aluminum-zinc Alloy | AZ |

| Surface Finish | Conventional Sequins | R |

| Minimize Sequins | M | |

| Skin Through | S | |

| Surface Treatment | Chromate Passivation | c |

| Non-chromate Passivation | C5 | |

| Chromate Passivationoiling | CO | |

| Chromium-free Passivationoiling | CO5 | |

| Anti-fingerprint | N | |

| Chromate-free/Anti-fingerprint | N5 | |

| No chromate high weather resistance fingerprint | NW | |

| Oil filling | 0 | |

| No treatment | U |

Material Comparison

|

Chinese Standard |

European Standards | American Standard | Japanese Standard |

| DC51D+AZ | DX51D+AZ | CS Type B, Type C | SGLCC |

| DC52D+AZ | DX52D+AZ | DS | SGLCD |

| S250GD+AZ | S250GD+AZ | 255 | – |

| S300GD+AZ | – | – | – |

| S350GD+AZ | S350GD+AZ | 345 | Class1 SGLC490 |

| S550GD+AZ | S550GD+AZ | 550 | SGLC570 |