1049 Carbon Steel Plates: Complete Guide for Industrial Use

Are you exploring options for high-quality steel? If so, you might have come across 1049 carbon steel plates. This article offers an in-depth look at 1049 carbon steel plates, covering their properties, applications, and how to choose the best product for your project. Whether you’re in manufacturing, construction, or engineering, understanding this steel grade is essential.

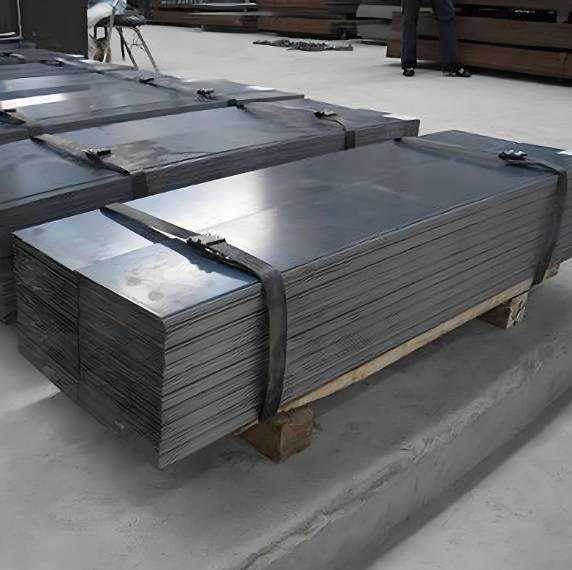

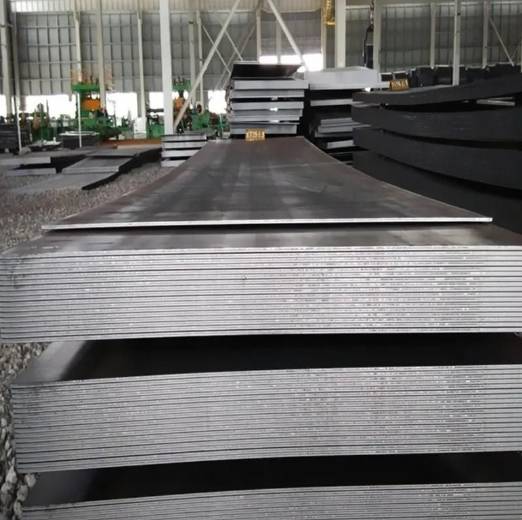

What Are 1049 Carbon Steel Plates?

1049 carbon steel plates are a type of medium carbon steel known for their strength, toughness, and good weldability. They contain approximately 0.49% carbon, which makes them a versatile choice for many industrial applications. These plates are often used where a balance between strength and ductility is needed.

Why Choose 1049 Carbon Steel Plates?

Compared to lower carbon steels, 1049 carbon steel plates provide higher tensile strength. They are suitable for parts that require durability and wear resistance. Additionally, their weldability ensures they can be easily fabricated into complex structures.

Mechanical and Physical Properties of 1049 Carbon Steel Plates

Mechanical Properties

| Property | Typical Range | Explanation |

|---|---|---|

| Tensile Strength | 620-820 MPa | Ensures durability under stress |

| Yield Strength | 370 MPa | Maintains structural integrity |

| Hardness | 170-220 HB | Suitable for machining and forming |

Physical Properties

- Density: 7.85 g/cm³

- Melting Point: 1420°C

- Thermal Conductivity: Moderate, suitable for heat transfer

Microstructure and Microhardness

The microstructure mainly consists of ferrite and pearlite, which contribute to its balanced properties. Heat treatment can further enhance its performance for specific needs.

Corrosion Resistance

While 1049 carbon steel plates have decent mechanical properties, they are susceptible to rust if not properly coated. Protective measures like galvanizing can extend their service life.

Sources:

- Steel Data Sheet, Steel Research Institute, 2023

- ASTM A516/A516M Specification, 2022

Applications of 1049 Carbon Steel Plates

1049 carbon steel plates are widely used across multiple industries. Here are some common applications:

- Automotive Components: Shafts, gears, and axles

- Construction: Structural beams and bridges

- Machinery: Frames and mechanical parts

- Shipbuilding: Hulls and structural panels

- Tool Manufacturing: Cutting tools and dies

Real-Life Example:

In my previous project, I used 1049 steel for fabricating high-strength shafts. Its excellent weldability and toughness made the process smooth, saving both time and money.

How to Select the Best 1049 Carbon Steel Plate

Choosing the right 1049 carbon steel plate involves careful consideration. Here’s a simple step-by-step guide:

Step 1: Define Your Project Requirements

Identify the mechanical properties needed, such as tensile strength, ductility, or hardness.

Step 2: Verify Material Certification

Ensure your supplier provides certified 1049 steel plates compliant with standards like ASTM or GB.

Step 3: Determine Surface Finish and Thickness

Select appropriate surface treatments and thicknesses based on your application.

Step 4: Evaluate Supplier Reputation

Partner with reputable companies like Shanxi Luokaiwei Steel Company for consistent quality.

Step 5: Confirm Delivery and Cost

Balance your budget with quality needs and confirm delivery timelines before finalizing.

Comparing 1049 Carbon Steel Plates with Other Grades

| Feature | 1049 Steel Plate | 1020 Steel Plate | 1050 Steel Plate |

|---|---|---|---|

| Carbon Content | ~0.49% | ~0.20% | ~0.50% |

| Tensile Strength | 620-820 MPa | 270-410 MPa | 700-900 MPa |

| Machinability | Good | Excellent | Moderate |

| Weldability | Good | Excellent | Fair |

| Cost | Moderate | Lower | Higher |

Note: The table helps visualize how 1049 carbon steel plates compare with similar grades, aiding in decision-making.

Common Mistakes When Using 1049 Carbon Steel Plates

⚠️ ⚠️ Warning:

- Overlooking proper surface preparation can cause weld defects.

- Ignoring heat treatment guidelines may weaken the material.

- Failing to apply protective coatings reduces corrosion resistance.

- Skipping quality verification risks purchasing substandard steel.

Step-by-Step Working with 1049 Carbon Steel Plates

Here’s a practical guide:

- Inspect the Material: Check for surface defects and certification documents.

- Cutting and Shaping: Use appropriate tools to avoid deformation.

- Heat Treatment: Apply tempering or annealing as required for your application.

- Welding: Follow recommended procedures to ensure strong joints.

- Finishing: Perform grinding or polishing for smooth surfaces.

Practical Tips for Working with 1049 Steel

- Always wear safety gear during handling and processing.

- Use lubricants during machining to extend tool life.

- Store plates in dry, covered areas to prevent rust.

- Regularly inspect welds for integrity.

- Consult with trusted suppliers like Shanxi Luokaiwei Steel Company for expert advice.

Final Inspection Checklist

- Confirm steel grade and certification

- Check surface quality and dimensions

- Verify mechanical properties meet specifications

- Ensure proper heat treatment and finishing

- Confirm packaging and delivery schedule

Conclusion

1049 carbon steel plates are a reliable choice for many industrial applications. Their strength, weldability, and affordability make them popular among engineers and manufacturers. To ensure the best results, always work with reputable suppliers like Shanxi Luokaiwei Steel Company. Contact us at [email protected] for high-quality 1049 steel plates tailored to your needs.