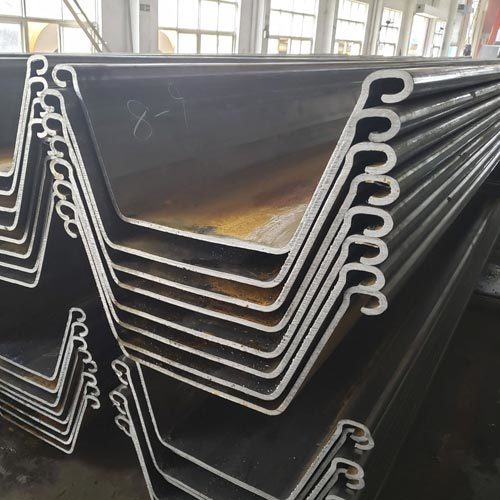

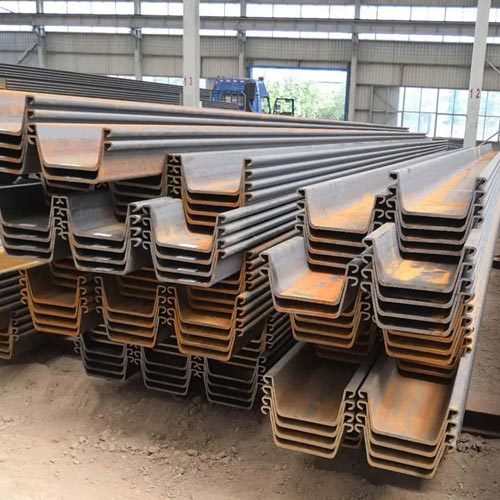

Z-Section Sheet Piles: High-Strength Interlocking Solutions for Permanent Retaining Systems

Z-section steel sheet piles feature an optimized zigzag profile that maximizes bending resistance (up to 5,200 kN·m/m) while minimizing material use. With Larssen or Hoesch interlocks positioned 85–110mm from the neutral axis, these piles achieve 15–25% higher section modulus than U-type alternatives. Compliant with ASTM A690 and EN 10249 standards, they dominate coastal protection, bridge abutments, and underground parking projects in North America.

Key Technical Specifications & Material Properties

Steel Grades & Mechanical Performance:

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Impact Toughness (-20°C) |

|---|---|---|---|

| S275 | ≥275 | 430–580 | ≥27J (EN 10045-1) |

| S355 | ≥355 | 510–680 | ≥35J |

| ASTM A690 | ≥345 | 485–620 | ≥40J (marine-grade) |

Dimensional Tolerances:

- Flange Width: 400–800 mm (±1.2% of nominal)

- Web Height: 90–180 mm (±1.5mm/m straightness)

- Thickness: 7.5–15.6 mm (±3% tolerance)

- Interlock Shear Capacity: 30–55 kN/cm²

Certifications: CE Marking, ISO 9001:2015, FPC, and AWS D1.8 seismic compliance.

Engineering Advantages Over Traditional Piling

- Superior Load Distribution: Z-profile reduces deflection by 18–22% in soft soil conditions.

- Saltwater Resilience: ASTM A690 grade offers 2.5x corrosion resistance vs. S355 in tidal zones.

- Rapid Installation: 45–60 linear meters/day with vibratory hammers (ICE 44S equipment).

- Lifecycle Cost Savings: 30-year design life with optional 400μm metallized coatings.

Critical Applications & Project Case Studies

Z-section piles excel in these scenarios:

- Marine Construction: Seawalls (ASTM A690, 14mm thickness, 22m length).

- Urban Infrastructure: Underground metro stations (S355, 12mm thickness).

- Industrial: LNG tank containment (SY390, hot-dip galvanized).

- Environmental: Landfill cutoff walls (S430, 3LPE coating).

Project Highlight: In Miami’s storm surge barrier project, 4,200 SY390 piles (24m length) withstood 4.5m wave forces while reducing installation time by 35% versus concrete alternatives.

Customization & Quality Assurance

Tailored Solutions:

- Length: 6m–80m (butt-welded for continuity).

- Coatings:

- Hot-Dip Galvanizing: 610 g/m² (85μm avg. thickness).

- Epoxy-Polyurethane Hybrid: 400–600μm salt spray resistance.

- Interlock Options:

- Larssen III: 55 kN/cm² shear capacity for heavy loads.

- Hoesch 700: Low-friction design for sandy soils.

Testing Protocols:

- Ultrasonic Flaw Detection: Class B per EN 10160.

- Interlock Watertightness: ≤1.5 liters/min per linear meter (BS 8002).

- Hardness Testing: 150–240 HV10 (Vickers scale).

Why Choose Our Z-Section Sheet Piles?

With a modulus of elasticity of 210 GPa and 0.91–1.25 section modulus ratio, our piles outperform competitors in lateral load scenarios. The JIS 5528-compliant production line ensures ±0.3° angular precision, while EN 10248 certification guarantees European market compliance.

Request a free soil-structure interaction analysis for your project. Download our Z-pile selection guide to compare grades, coatings, and interlock types based on soil class (CL, ML, or SP).

Packaging: Bare bundles with nylon sling protection; 40ft container holds 25–32 tons.

Lead Time: 18–30 days for stock grades; 50–65 days for custom-coated orders.

Product Show

G90 Galvanized Sheet supplier

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.