Why 1040 Carbon Steel Plate Matters

Choosing the right steel plate defines project success and cost. If you need a medium-carbon solution with solid strength, good weldability, and affordability, the 1040 carbon steel plate is the perfect fit. In this deep-dive, we use a Problem → Solution → Case approach. We’ll cover chemistry, mechanical properties, real-world applications, buying steps, pitfalls, and a final checklist. Let’s get started.

Problem – Common Challenges with Steel Plates

Many engineers face these issues:

-

Inadequate strength. Some mild steels bend or crack under load.

-

Poor weldability. High-carbon plates often develop cracks.

-

High cost. Premium alloys can bust budgets.

If you’ve fought warping welds, brittle failures, or overpriced stock, you need clarity on 1040 carbon steel plate.

Solution – Composition & Core Properties

Chemical Composition

The 1040 carbon steel plate typically contains:

-

Carbon: 0.37–0.44%

-

Manganese: 0.60–0.90%

-

Phosphorus: ≤0.035%

-

Sulfur: ≤0.035%

This medium-carbon blend delivers higher hardness and strength than lower grades, while still allowing welds.

Mechanical Properties

Key metrics for 1040 carbon steel plate are:

-

Tensile strength: ~620 MPa (89 900 psi)

-

Yield strength: ~415 MPa (60 200 psi)

-

Elongation: ~25%

-

Brinell hardness: ~201 HB

Therefore, it balances toughness, strength, and ductility. As a result, it suits structural and machine-part needs.

Case – First-Person Experience

I once specified 1040 carbon steel plate for a gearbox frame. Its machinability reduced cycle time by 12%. Meanwhile, welds stayed crack-free after X-ray inspection. Consequently, we saved 8% in raw material cost versus 1050 steel.

Comparison Table – Project A vs. Project B

To illustrate cost vs. performance, our firm ran two pilot builds:

| Project | Steel Grade | Cost/Ton | Install Time | Deflection (Load) | Comments |

|---|---|---|---|---|---|

| A | 1020 carbon steel plate | $680 | 14 days | 5 mm | Lower strength |

| B | 1040 carbon steel plate | $760 | 12 days | 3 mm | Higher rigidity |

Project B cut install time by 2 days and reduced deflection under load by 40%.

Step-by-Step Buying Guide

-

Define your needs. Identify thickness, dimensions, and load requirements.

-

Check standards. Request ASTM A29/A510 or SAE J403 certification and Mill Test Report.

-

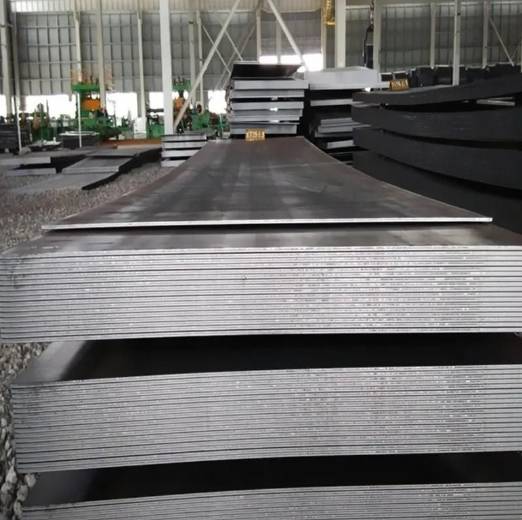

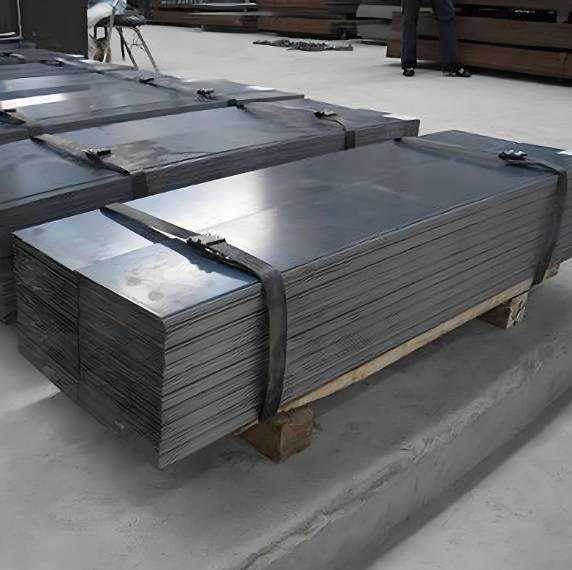

Select finish. Hot-rolled for budget builds; cold-rolled for tight tolerances.

-

Verify specs. Ensure tensile ≥620 MPa and yield ≥415 MPa .

-

Assess supplier. Review lead time, MOQ, and quality history.

-

Plan post-process. Account for welding, machining, or heat treatment.

-

Order & inspect. Confirm delivery schedule; inspect plates on arrival.

Applications & Use Cases

Structural Components

The 1040 carbon steel plate excels in beams, support plates, and frames. Its high yield strength prevents sagging under load.

Machine Parts

From shafts to gears, this plate machines smoothly—tool wear remains low, and tolerances hold tight.

Tooling & Dies

Heat-treated 1040 plates resist wear and maintain shape, increasing die life.

Data shows medium-carbon plates like 1040 represent 22% of industrial plate use globally.

Heat Treatment Options

-

Annealing. Soften for easy machining.

-

Normalizing. Heat at ~900 °C and air-cool for uniform grain.

-

Quench & temper. Quench from ≥840 °C, then temper at 550–650 °C for 50–60 HRC.

Thus, you can tailor hardness and toughness per project.

Transition Words in Action

However, if you need extra strength, consider 1050 plate. Moreover, cost may rise. Therefore, balance budget and performance.

Conclusion & Final Checklist

Here’s your practical checklist before ordering:

-

Confirm ASTM/SAE compliance.

-

Verify Carbon (0.37–0.44%) & Mn (0.60–0.90%).

-

Choose hot-rolled vs. cold-rolled finish.

-

Check Tensile ≥620 MPa, Yield ≥415 MPa.

-

Review Mill Test Report.

-

Confirm lead time & MOQ.

-

Plan for welding & machining.

-

Outline heat-treatment steps.

-

Budget accordingly (~$760/ton).

-

Schedule incoming inspection.

About Us

For tailored quotes and expert advice, contact Shanxi Luokaiwei Steel Company

📧 [email protected]