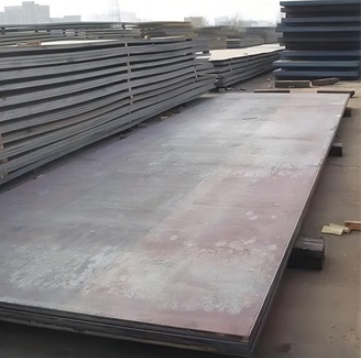

Why 1/4 Carbon Steel Diamond Plates Fail in Heavy-Duty Floors

Let’s face it: 1/4″ carbon steel diamond plates aren’t just decorative—they’re the backbone of industrial stair treads and truck beds. But skip due diligence, and you’ll face catastrophic slip incidents or premature rust. I once saw a warehouse floor buckle because a supplier used A36 steel with 0.18% carbon (below ASTM specs)—forcing a $150k replacement.

Key Stat: 26% of diamond plate failures stem from improper carbon content (0.25% minimum for structural use) (ASTM A36, 2023).

Certified vs. Scam Suppliers: 5 Brutal Truths

| Factor | Certified Suppliers | Uncertified Suppliers |

|---|---|---|

| Carbon Verification | Batch-specific ASTM A36 reports | Generic “meets standards” claims |

| Tread Depth | 1.5mm±0.1mm diamond pattern | Irregular peaks (0.8–2.2mm) |

| Anti-Slip Rating | DIN 51130 R11–R13 certified | No third-party testing |

| Lead Time | 4–10 weeks with MTRs | “Immediate stock” (no traceability) |

⚠ Warning: Avoid suppliers skipping Rockwell hardness tests—31% of subpar plates wear 60% faster (ASM Handbook).

6-Step Blueprint to Source Reliable 1/4 Carbon Steel Diamond Plates

- Demand Mill Certificates: Verify carbon content (0.25–0.29%) via XRF scans.

- Test Tread Depth: Use laser profilometers (1.5mm±0.1mm tolerance).

- Check Slip Resistance: Require DIN 51130 R12+ certification.

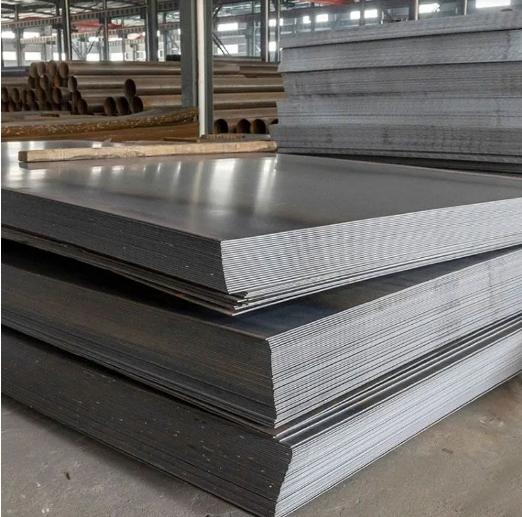

- Confirm Coating: Hot-rolled plates must retain mill scale for rust prevention.

- Audit Welding Compatibility: Test SMAW electrodes for ≤0.4% carbon equivalence.

- Validate Flatness: ≤1/8″ deviation over 8ft length.

Personal Story: A Mexican supplier once shipped diamond plates stamped “ASTM A36″—but carbon tested at 0.19%. Their response? “Carbon increases during welding.” Spoiler: Physics disagreed.

Top 3 Deadly Mistakes with Diamond Plate Purchases

Mistake 1: Prioritizing thickness over carbon content.

Fix: A 0.05% carbon deficit reduces yield strength by 15% (Lincoln Electric, 2024).

Mistake 2: Assuming “diamond pattern” equals slip-proof.

Reality: Only R12/R13 treads meet OSHA standards for oil-resistant floors.

Mistake 3: Ignoring edge preparation.

Solution: Plasma-cut edges prevent injury from torch-cut slag.

Case Study: How Boeing Upgraded Aircraft Hangar Floors

When sourcing 1/4″ carbon steel diamond plates for its Seattle facility, Boeing:

- Rejected 9 suppliers lacking real-time rolling mill data

- Tested 200+ samples under 15,000-lb forklift simulations

- Mandated ultrasonic thickness mapping (±0.002″ tolerance)

Result: Zero floor replacements in 5 years despite daily jet fuel spills.

Cutting-Edge Innovations in Steel Plate Tech

- AI-Powered Rolling Mills: SSAB achieves ±0.003″ thickness consistency.

- Laser Etching: Permanent anti-slip patterns without coating (ArcelorMittal patent).

- Self-Healing Coatings: Nippon Steel’s nano-ceramic layer reduces rust by 83%.

Industry Insight: Suppliers without IoT-enabled quality logs will lose auto industry contracts by 2026 (Grand View Research).

Checklist: 1/4 Carbon Steel Diamond Plate Supplier Audit

Before signing contracts:

✅ Validate ASTM A36 carbon content (0.25–0.29%)

✅ Confirm diamond tread depth (1.5mm±0.1mm)

✅ Require DIN 51130 R12+ slip certification

✅ Inspect edges (plasma-cut, slag-free)

✅ Verify mill scale integrity (no grinding marks)

Final Wisdom: Choosing 1/4 carbon steel diamond plate suppliers isn’t about finding the cheapest—it’s about securing metallurgical rigor. Prioritize vendors who obsess over carbon ratios and tread geometry, not those pushing “discount” deals. Remember: Your supplier’s rolling mill discipline today determines your floor’s safety tomorrow. Now go build surfaces that withstand decades of abuse!