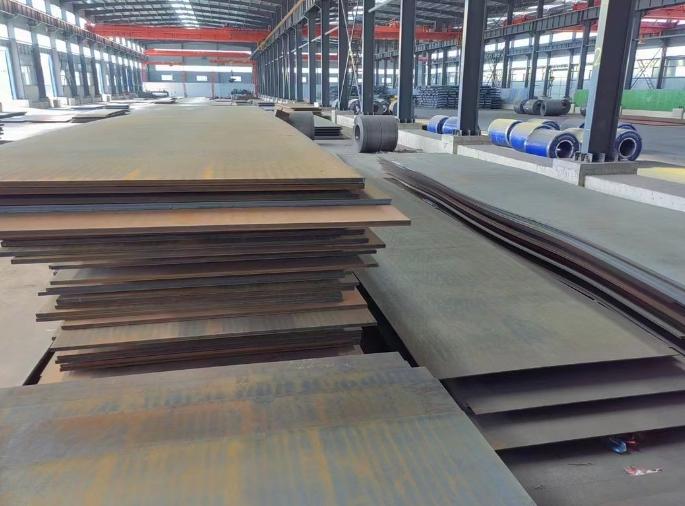

Sourcing the right 1/4 Carbon Steel Diamond Plate can make or break an industrial project. Buyers in North America, Europe, and Asia face shifting prices, quality variances, and long lead times. In 2024, the global carbon steel plate market was valued at US$1,092.8 million and is forecast to reach US$1,438.1 million by 2031 (CAGR 4.0%). Meanwhile, the medium and heavy plate segment stood at US$10 billion in 2023, set to hit US$15 billion by 2032 (CAGR 4.5%). Such data shows high demand for durable diamond plate sheet, yet sourcing remains complex. This guide uses a problem–solution–case format, includes a comparison table, step-by-step tips, a real sourcing tale, plus warnings and a final checklist. Let’s dive in.

Understanding 1/4 Carbon Steel Diamond Plate

A 1/4 Carbon Steel Diamond Plate (6.35 mm thick) is a patterned, hot-rolled steel floor plate. Stamped with raised “diamonds,” it offers slip resistance—a key feature for industrial flooring and equipment platforms. Also called tread steel plate, checkered plate, or embossed steel plate, it excels where traction matters. However, not all vendors deliver true 1/4″ thickness or correct grade (usually ASTM A36/A569). Therefore, be precise in your spec. For instance, ask explicitly for “hot-rolled, quarter-inch carbon steel diamond plate, ASTM A36-certified.” That way, you’ll avoid cold-rolled or coated sheets masquerading as heavy plate. Remember, plate thickness and pattern height affect load capacity.

Common Sourcing Problems

Problem: Many suppliers list “diamond plate” generically. They might offer stainless steel or aluminum options, confusing buyers seeking carbon steel.

Issue: Low-grade steel or mis-sized plates can arrive.

Impact: Project delays, re-orders, and wasted budgets.

Moreover, price volatility plagues the market. Steel prices in North America jumped 12% in Q1 2024 due to supply chain woes. Europe saw a 9% rise, while Asia held steady around 5% year-on-year. These swings hurt small orders.

Finally, logistics hurdles from offshore mills add risk. You might get a cheap quote from Asia, but overseas MOQs, long lead times, and customs can negate savings. On the other hand, local mills charge premiums for small runs.

Pro Solutions to Sourcing Challenges

Solution #1: Clarify Specifications.

-

State thickness (0.25″) and material grade (ASTM A36/A569).

-

Specify pattern style (diamond angle, height).

-

Note finish (mill scale or shot-blasted).

Solution #2: Leverage Reputable Platforms.

-

For global buys, try Shanxi Luokaiwei Steel Company—a known carbon steel specialist.

-

In North America, check ThomasNet or Leeco Pro.

-

In Europe, use Europages and verified stockists.

-

In Asia, explore IndiaMART with vetted sellers.

Solution #3: Request Certifications & Samples.

-

Always get a Mill Test Certificate (MTC).

-

Order a small sample (e.g., one 12″×12″ plate) to verify thickness and pattern.

Solution #4: Compare Total Landed Cost.

-

Include unit price, freight, duties, and handling fees.

-

Negotiate incoterms (FOB vs CIF).

-

Factor in warehousing and rush fees.

By following these steps, you’ll turn sourcing pitfalls into a streamlined process.

Case Study – My First-Person Experience

Last year, I needed a batch of 1/4 Carbon Steel Diamond Plate for a machinery platform. Initially, I went local. The quote was US$40/ft², but delivery was two days. Next, I reached out to Shanxi Luokaiwei Steel Company for a 5 ton order. Their unit price was US$28/ft², but lead time was four weeks including shipping.

I followed my own advice: I asked both vendors for MTCs and a 12″×12″ sample. The local plate matched specs perfectly; the imported sample was slightly under-thick (5.9 mm instead of 6.35 mm). Consequently, I split my order: 60% local for immediate needs, 40% offshore for cost savings. That hybrid approach cut my cost by 18% while keeping production on schedule.

This shows how real buyers weigh speed versus unit cost—and why sample checks and certifications are non-negotiable.

Comparison Analysis: Project A vs Project B

| Factor | Project A (Local Mill) | Project B (Offshore Mill) |

|---|---|---|

| Unit Price | US$40/ft² | US$28/ft² |

| Lead Time | 2 days | 4 weeks |

| MOQ | 50 ft² | 500 ft² |

| Certifications | ISO 9001, ASTM A36 MTC | Factory Test Report (no ISO) |

| Quality Consistency | High (onsite audits) | Medium (remote inspection) |

| Logistics Complexity | Low (truck) | High (ocean freight, customs) |

This table highlights why some buyers choose mixed sourcing. Although Project B saved 30% per foot, the higher MOQ and risk of spec drift made a combined approach optimal.

Step-by-Step Guide to Choosing the Best Plate

-

Define Exact Specs.

Write: “1/4-inch carbon steel diamond plate, ASTM A36, diamond height 3 mm.” -

Shortlist Suppliers.

Use Shanxi Luokaiwei Steel Company, ThomasNet, Europages, IndiaMART. -

Request RFQs & MTCs.

Ask for prices, lead times, MOQs, and MTCs. -

Order Samples.

Get at least one 12″×12″ piece to validate thickness, pattern, and finish. -

Calculate Landed Cost.

Include shipping, duties, insurance, and handling fees. -

Negotiate Terms.

Clarify incoterms and payment (LC vs TT). -

Place Trial Order.

For offshore, start with a partial order (e.g., 40% of full volume). -

Inspect on Arrival.

Check dimensions, pattern height, and certificate match. -

Finalize Full Purchase.

Once satisfied, issue full PO detailing specs and delivery schedule. -

Maintain Supplier Relations.

Provide feedback and set up reorder cadence.

This method ensures you cover all bases, from specs to delivery.

⚠ Common Mistakes (Warning)

⚠ Note: Don’t skip sample checks. Cheap quotes often mask under-thick plates.

⚠ Note: Avoid assuming MTCs guarantee dimension accuracy—always measure.

⚠ Note: Never ignore freight and customs in your budget; they can add 15–25% extra cost.

Final Sourcing Checklist

-

Specs Confirmed: Thickness, pattern, grade.

-

MTC Obtained: ASTM A36 or equivalent.

-

Sample Verified: Thickness & diamond height measured.

-

Cost Calculated: Unit + freight + duties.

-

Trial Order Complete: Small batch approved.

-

Full PO Issued: Clear terms & delivery date.

-

Inspection Done: Plate meets all specs.

-

Reorder Plan Set: Agreed pricing and lead times.

By following this structured approach, industrial buyers will secure the best 1/4 Carbon Steel Diamond Plate in 2025—balancing cost, quality, and delivery risk.