When it comes to structural applications and manufacturing, choosing the right steel grade is crucial. Among various options, medium carbon steel plate stands out for its strength and versatility. This article explores the ASTM standards governing medium carbon steel plate, its common uses, and practical insights to help you make informed decisions for your projects.

What Is Medium Carbon Steel Plate?

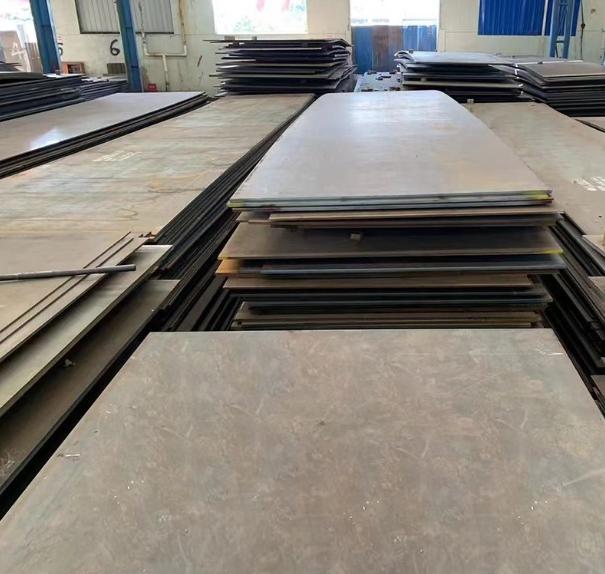

Defining Medium Carbon Steel Plate

Medium carbon steel plate typically contains 0.30% to 0.60% carbon. This composition offers a balanced mix of strength, toughness, and weldability. It’s widely used in industries requiring durable materials, such as construction, machinery, and automotive manufacturing.

Why Is It Popular?

The steel’s properties make it ideal for applications demanding higher strength than low carbon steels but with manageable fabrication processes. Its ability to withstand wear and tear while maintaining ductility makes medium carbon steel plate a go-to choice.

ASTM Standards for Medium Carbon Steel Plate

Overview of Relevant ASTM Standards

The American Society for Testing and Materials (ASTM) provides comprehensive specifications for medium carbon steel plate. The most relevant standards include:

- ASTM A36: General purpose structural steel.

- ASTM A572: High-strength low-alloy steel.

- ASTM A516: Pressure vessel plates.

Each standard specifies chemical composition, mechanical properties, and testing procedures to ensure quality and consistency.

How These Standards Impact Your Project

Adhering to ASTM standards guarantees that medium carbon steel plate meets safety and performance benchmarks. For example, ASTM A36 ensures the steel’s yield strength is at least 36,000 psi, suitable for most structural applications.

Common Uses of Medium Carbon Steel Plate

Industry Applications

Medium carbon steel plate is extensively used in:

- Structural components: Beams, bridges, and frameworks.

- Machinery parts: Shafts, gears, and axles.

- Automotive parts: Crankshafts and suspension components.

- Pressure vessels: Storage tanks and boilers.

Real-World Case

In my experience, a manufacturing plant used medium carbon steel plate to produce heavy-duty gearboxes. The steel’s strength and machinability allowed for precise manufacturing, reducing costs and increasing durability.

Comparing Medium Carbon Steel Plate with Other Steel Grades

| Property | Medium Carbon Steel Plate | High Carbon Steel | Low Carbon Steel |

|---|---|---|---|

| Carbon Content | 0.30%-0.60% | >0.60% | <0.30% |

| Strength | Moderate | Very high | Low |

| Ductility | Good | Moderate | Excellent |

| Welding | Easy | Difficult | Very easy |

| Typical Uses | Machinery, structural | Cutting tools, springs | Construction, fencing |

Source: Steel Industry Data, 2023

How to Work with Medium Carbon Steel Plate

Step-by-Step Fabrication Guide

- Material Selection: Confirm the steel grade aligns with project needs.

- Cutting: Use plasma or laser cutting for precision.

- Heating and Quenching: For hardening, heat to 800°C and quench in oil.

- Machining: Use carbide tools for shaping.

- Welding: Preheat to reduce cracking; avoid excessive heat input.

- Finishing: Grind and polish for smooth surfaces.

- Inspection: Check for cracks, warping, or surface defects.

- Coating: Apply protective layers to prevent corrosion.

Tips for Success

Always ensure your equipment is calibrated. Proper handling minimizes defects and prolongs the material’s lifespan.

Common Mistakes and How to Avoid Them

⚠️ Note: Do not ignore the heat treatment process; improper hardening can weaken the steel.

⚠️ Note: Avoid excessive welding heat, which can cause cracking.

⚠️ Note: Be cautious with cutting methods—using the wrong technique may lead to deformation.

Comparing Projects Using Medium Carbon Steel Plate

Here’s a quick comparison of two typical projects:

| Project | Material | Thickness | Strength | Cost | Application |

|---|---|---|---|---|---|

| Bridge Support | ASTM A36 | 10 mm | Moderate | Low | Structural support |

| Gear Manufacturing | ASTM A572 | 15 mm | High | Moderate | Mechanical parts |

This comparison highlights how selecting the right medium carbon steel plate depends on specific project requirements.

Real-Life Experience

I once worked on a project where we used medium carbon steel plate for manufacturing heavy-duty gears. The challenge was achieving high precision while maintaining strength. By following proper heat treatment and cutting techniques, we succeeded. This experience taught me the importance of understanding material properties for optimal results.

Common Pitfalls to Watch Out For

⚠️ Note: Rushing the heat treatment process can lead to brittle steel.

⚠️ Note: Not verifying chemical composition may result in non-compliance with standards.

⚠️ Note: Skipping surface inspections can cause unnoticed defects, risking failure.

Final Practical Checklist

- Confirm steel grade and ASTM compliance.

- Inspect chemical composition and mechanical properties.

- Use appropriate cutting tools (laser, plasma).

- Follow proper heat treatment procedures.

- Ensure welding is performed with preheating.

- Conduct surface and dimensional inspections.

- Apply protective coatings if necessary.

- Document all process parameters and results.

Conclusion

Medium carbon steel plate is a versatile material that balances strength, weldability, and cost-efficiency. Understanding the relevant ASTM standards ensures high-quality fabrication and safety. Whether you’re building bridges or manufacturing machinery, selecting the right grade and following proper procedures are key. Keep these insights in mind, and you’ll be well on your way to successful projects.