JIS G3114 SMA570P Corten Steel: Advanced Weathering Steel for Structural Longevity & Cost Efficiency.

Built for Harsh Environments: Bridges, Railcars & Industrial Machinery

JIS G3114 SMA570P is a high-performance weathering steel (Corten steel) engineered to resist atmospheric corrosion 3–5x better than standard carbon steel. Its patented self-regenerating oxide layer forms under alternating wet/dry cycles, eliminating painting needs in bridges, shipping containers, and power plant components like economizers.

Certifications & Core Benefits

- JIS G3114 & ASTM A871 Certified: Compliant with EN 10025-5 for structural reliability.

- Cost Savings: 35% lower lifetime costs vs. painted alternatives due to zero upkeep.

- Custom Dimensions: Thickness 3–150mm (±0.5mm), width up to 4,000mm.

- MOQ 1 Ton: Available as plates, sheets, or structural sections (U-channels, H-beams).

Technical Specifications

Chemical Composition (Weight %)

| Element | C (max) | Si (max) | Mn (max) | P (max) | S (max) | Cr | Cu |

|---|---|---|---|---|---|---|---|

| SMA570P | 0.18 | 0.55 | 1.40 | 0.035 | 0.035 | 0.30–0.55 | 0.20–0.35 |

Alloy Design:

- Chromium (0.30–0.55%): Forms a stable rust barrier to halt corrosion spread.

- Copper (0.20–0.35%): Enhances atmospheric resistance in coastal/industrial zones.

- Low Carbon (0.18%): Optimizes weldability (AWS D1.5 compliant) without sacrificing strength.

Mechanical Properties

| Yield Strength (Rp0.2) | Tensile Strength (Rm) | Elongation (A50) | Charpy Impact (-20°C) | Hardness (HBW) |

|---|---|---|---|---|

| 420–460 MPa | 570–720 MPa | 19–26% | ≥25J (EN ISO 148-1) | 140–190 |

Performance Highlights:

- 720 MPa Tensile Strength: 20% stronger than SMA570W variants.

- 25J Impact Toughness: Suitable for subzero Arctic infrastructure projects.

- Versatile Processing: Hot-rolled, TMCP, or QT-treated for precision tolerances.

Applications

- Infrastructure: Bridge girders, transmission towers, and highway signposts.

- Transportation: Railcar underframes, container walls, and trailer chassis.

- Energy: Air preheater ducts, boiler casings, and chimney liners.

- Architecture: Sculptures, sunshades, and rooftop support beams.

Fabrication Guidelines

- Cutting: Laser or plasma (pre-heat to 100°C for thickness >30mm).

- Welding: Use E7018-G electrodes with 120–150°C preheat (AWS D1.5).

- Bending: Minimum radius = 3x plate thickness (cold-formed).

- Patina Development: Requires 6–24 months of outdoor exposure for full corrosion resistance.

Quality Assurance

- Ultrasonic Testing: EN 10160 Class E1 for defect-free consistency.

- Salt Spray Test: 1,000+ hours (ASTM B117) validating corrosion performance.

- Certifications: EN 10204 3.1 MTRs, CE, and PED compliance.

Competitive Edge

- Lifespan: 50+ years in coastal/industrial environments without coatings.

- Lead Time: 15–25 days (MOQ 1 ton).

- Sustainability: 100% recyclable with 18% lower CO₂ emissions than stainless steel.

Logistics & Compliance

- Packaging: VCI film + edge guards for.

- Temperature Limits: Suitable for -40°C to 380°C service.

- Custom Coatings: Optional galvanized (GI) or Al-Zn (AZ) finishes.

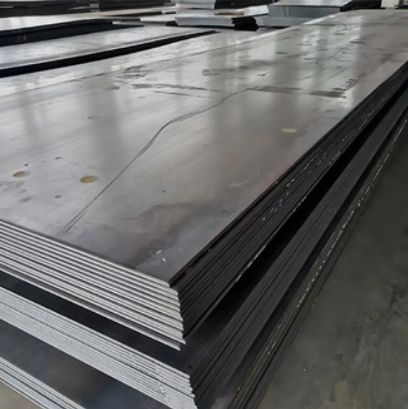

Product Show

Supplier of various types of carbon steel

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.