High-Strength Welded Structural Steel Pipes: Engineered for Heavy-Duty Construction.

Welded Structural Pipes: ASTM A500 & EN 10219 Compliance.

Designed for load-bearing frameworks in bridges, towers, and industrial plants, these pipes combine 88.9–660mm (3.5″–26″) diameters with 3–17.5mm walls to achieve yield strengths up to 560 MPa (A500 Gr.3). Available in 0.5–22m lengths (SRL/DRL), they meet EN 10219-1 for cold-formed hollow sections and ASTM A500 for structural tubing.

Key Specifications & Material Grades

| Parameter | ASTM A500 Gr.1 | ASTM A500 Gr.3 | EN 10219 S355J2H |

|---|---|---|---|

| Yield Strength | 270 MPa | 560 MPa | 355 MPa |

| Tensile Strength | 310–465 MPa | 620–725 MPa | 470–630 MPa |

| Elongation | ≥20% | ≥15% | ≥22% |

Surface Options:

- Galvanized: 85μm zinc coating (ISO 1461)

- 3PE Coating: 2.5mm polyethylene layer for corrosion resistance

Chemical Composition & Mechanical Properties

Alloy Steel Grades (4130/4140)

| Element | 4130 | 4140 | 1045 | Application |

|---|---|---|---|---|

| C% | 0.28–0.33 | 0.38–0.43 | 0.43–0.50 | High-stress crane booms |

| Cr% | 0.80–1.10 | 0.80–1.10 | – | Oil rig derricks |

| Mo% | 0.15–0.25 | 0.15–0.25 | – | Mining equipment frames |

Post-Weld Treatment:

- Stress Relieving: 600–650°C for Gr.3 pipes

- Normalizing: 890°C (4130) to refine grain structure

Dimensional Tolerances & Load Capacities

| OD (mm) | Wall Thickness | Max Axial Load (kN) | Typical Use Case |

|---|---|---|---|

| 114.3 | 6.0mm | 1,240 | Warehouse roof trusses |

| 323.9 | 12.7mm | 5,880 | Wind turbine tower segments |

| 508 | 17.5mm | 12,400 | Bridge cantilever supports |

Weight Formula:

- kg/m = (OD – WT) × WT × 0.02466

- Example: 219mm OD × 8mm wall = 41.6 kg/m

Applications by Industry

- Civil Engineering:

- Seismic Bracing: 406mm S355J2H pipes with 14mm walls (EN 1998).

- Highway Signposts: 168mm Gr.1 pipes, hot-dip galvanized.

- Energy Sector:

- Solar Mounts: 140mm A500 Gr.3 pipes with anti-UV coating.

- Material Handling:

- Conveyor Galleries: 660mm × 17.5mm pipes for mining operations.

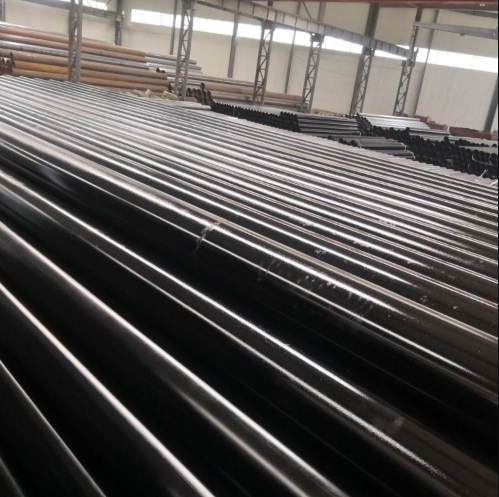

Product Show

Supplier of various types of carbon steel

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.