Carbon steel grades are primarily classified based on carbon content, which directly influences their mechanical properties and applications. Carbon steel is an alloy of iron and carbon with up to 2.1% carbon content.

1. Low-Carbon Steel (Mild Steel)

-

Carbon Content: 0.05–0.25%.

-

Properties: High ductility, excellent weldability, and machinability; low hardness and strength. Cannot be hardened via heat treatment but can be strengthened by cold working.

-

Common Grades:

-

AISI 1018, 1020, Q235 (structural steel).

-

08F, 20 (used for automotive panels, bolts, and welded structures).

-

-

Applications: Sheet metal, bolts, machine parts with low strength requirements, and structural components like rebar.

⚙️ 2. Medium-Carbon Steel

-

Carbon Content: 0.30–0.60%.

-

Properties: Balanced strength and ductility; responds well to heat treatment (e.g., quenching and tempering). Harder to machine than low-carbon grades but offers higher wear resistance.

-

Common Grades:

-

AISI 1045 (shafts, gears).

-

45, 40Mn (Chinese grades for gears, axles).

-

AISI 1141 (sulphur-added for improved machinability).

-

-

Applications: Gears, connecting rods, axles, and tools requiring toughness.

⛏️ 3. High-Carbon Steel (Tool Steel)

-

Carbon Content: 0.60–1.50%.

-

Properties: High hardness and wear resistance; low ductility and poor weldability. Hardened via rapid cooling after heating.

-

Common Grades:

-

AISI 1095, T7–T13 (carbon tool steels).

-

EN 10088-3 (high-hardness applications).

-

-

Applications: Cutting tools, springs, knives, and wear-resistant parts.

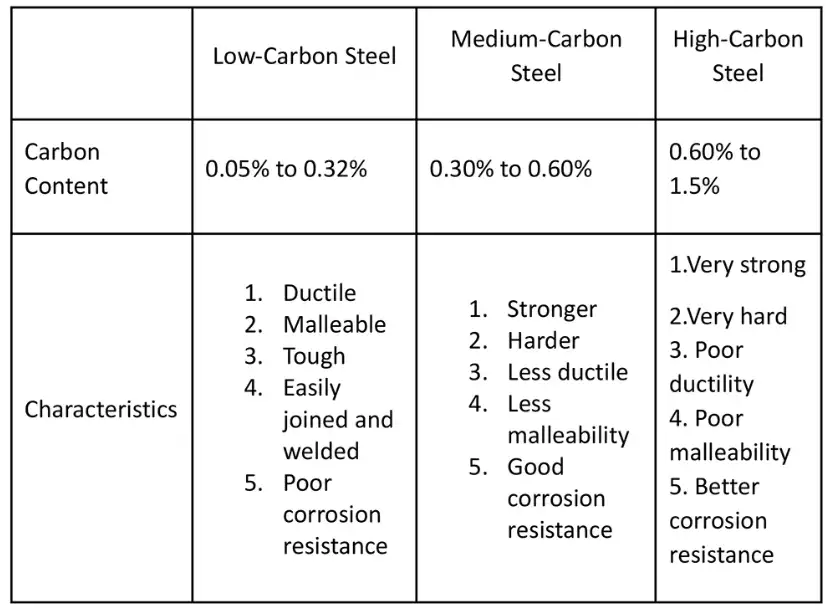

📊 Key Comparison of Carbon Steel Grades

| Type | Carbon Range | Key Properties | Example Grades | Primary Applications |

|---|---|---|---|---|

| Low-Carbon | 0.05–0.25% | High ductility, weldable, machinable | 1018, Q235, 20 | Bolts, panels, structural parts |

| Medium-Carbon | 0.30–0.60% | Balanced strength/ductility, heat-treatable | 1045, 45#, 1141 | Gears, shafts, connecting rods |

| High-Carbon | 0.60–1.50% | High hardness, wear-resistant | T12, 1095, EN 10088-3 |

These categories help engineers choose the appropriate material by balancing formability against strength and wear resistance. Moreover, recognizing that subtle compositional tweaks (e.g., manganese, silicon) can tailor performance is crucial.

3. Chemical Composition Ranges

Below is a simplified overview of typical grades:

| Grade | C (%) | Mn (%) | Si (%) | P + S (%) max | Notes |

|---|---|---|---|---|---|

| ASTM A36 | 0.25–0.29 | 0.80–1.20 | 0.15–0.40 | 0.040 | Structural steel |

| AISI 1045 | 0.43–0.50 | 0.60–0.90 | ≤0.40 | 0.050 | Shafts, gears |

| AISI 4140 | 0.38–0.43 | 0.75–1.00 | 0.15–0.35 | 0.040 | Alloy steel, quenched & tempered |

| AISI 4340 | 0.38–0.43 | 0.60–0.80 | 0.15–0.30 | 0.040 | High‑strength forgings |

Transitions matter. However, these numbers only tell part of the story; heat treatment and microstructure play equally pivotal roles.

4. Mechanical Properties Comparison

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| A36 | 400–550 | 250–350 | ≥20 | 120–180 |

| 1045 | 570–700 | 310–460 | ≥16 | 180–220 |

| 4140 QT | 655–880 | 415–725 | ≥12 | 197–241 |

| 4340 HT | 790–930 | 620–860 | ≥10 | 217–269 |

For instance, A36’s ductility supports complex forming. Conversely, 4340’s high yield strength suits heavy‑duty applications. Data from ASM International shows A36 yield around 250 MPa and 4140 QT tensile up to 880 MPa.

5. Industry Standards and Specifications

Key authorities include:

-

ASTM International: A36, A285, A572

-

SAE/AISI: 1005–1095 series

-

EN 10025: S235, S355

-

JIS G3101: SS400

Standards define chemical, mechanical, test methods, and permissible variations. Therefore, always verify mill certificates against the relevant standard.

6. Heat Treatment Effects on Properties

Heat treatment can transform:

-

Annealing: increases ductility.

-

Quenching & Tempering: boosts strength & toughness.

-

Normalized: refines grain size.

For example, normalizing A36 at ~900 °C improves uniformity. Nevertheless, over‑quenching can induce brittleness.

7. Case Study: Pipeline Material Selection

Background: A municipal water authority needed pipe fittings resistant to internal pressure and corrosive elements.

Grades Evaluated:

-

A36: easy fabrication, lower strength.

-

4140 QT: excellent strength, costlier.

-

1045 H: moderate cost, balanced properties.

Decision: 4140 QT was chosen, offering 725 MPa yield and HAZ toughness—critical for 10 bar service pressure. Fabrication costs rose by 8 %, yet lifecycle savings justified the choice.

8. Applications by Grade

-

A36: structural beams, frames, general fabrication.

-

1045: shafts, sprockets, pistons.

-

4140: crankshafts, high‑strength gears.

-

4340: aircraft landing gear, heavy‑duty fasteners.

9. Selecting the Right Grade: Key Considerations

I typically assess:

-

Load requirements: static vs. dynamic.

-

Formability: bends, welds.

-

Corrosion: mild vs. severe environments.

-

Heat treatment capability: in‑house vs. outsourced.

-

Cost constraints: material and processing bills.

Moreover, consulting suppliers like Luokaiwei early ensures material availability.

10. Sustainability and Lifecycle

Recycled scrap content in carbon steel exceeds 80 % globally. Choosing grades with high recyclability minimizes environmental impact. Lifecycle assessments reveal that heat treatment energy can outweigh initial production energy by up to 30 %.

11. Frequently Asked Questions

1. What’s the difference between A36 and S355?

A36 is an ASTM spec with 250 MPa yield; S355 is EN spec with 355 MPa, offering higher strength and better impact toughness.

2. Can I weld high‑carbon steel without cracking?

Yes, but pre‑heating and post‑weld tempering reduce residual stresses and avoid cold cracking.

3. How do I verify grade authenticity?

Request mill test certificates (MTC) showing chemical analysis, mechanical tests, and heat numbers.

4. Is 4140 suitable for corrosive environments?

Not inherently; consider coatings or stainless alternatives for severe exposure.

5. What’s normalizing vs. annealing?

Normalizing refines grains at higher temps; annealing softens steel more fully for easy machining.