1045 carbon steel is a medium-carbon steel grade that offers a perfect balance of strength, toughness, and machinability. It is commonly used in applications where durability and performance are crucial. As a medium-carbon steel, it typically contains 0.43-0.50% carbon, making it suitable for forging, heat treatment, and surface hardening. Its ability to harden and strengthen by heat treatment makes it one of the most widely used carbon steels for various industrial applications.

1. Overview of 1045 Carbon Steel

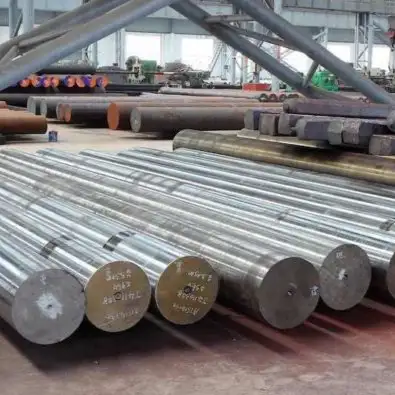

1045 carbon steel, often referred to as medium carbon steel, is commonly utilized in applications that require high strength and moderate hardness. This material strikes a balance between hardness and flexibility, making it ideal for structural components such as shafts, gears, and machine parts that need to be tough and wear-resistant.

2. Key Properties and Characteristics

1045 steel stands out due to its ability to be heat-treated to achieve different levels of hardness and strength. It offers a good combination of ductility and toughness, which makes it versatile across various industries. Below are the key properties of 1045 carbon steel:

-

Carbon Content: 0.43-0.50%

-

Tensile Strength: Typically between 85,000-100,000 psi

-

Yield Strength: Approximately 55,000 psi

-

Hardness: Ranges from 170 to 200 BHN (Brinell hardness number)

-

Machinability: 65% (based on B1112)

-

Weldability: Medium to high

-

Formability: Good at room temperature but can become more brittle at lower temperatures.

These properties make it highly suitable for processes like forging, turning, and milling.

3. Common Uses of 1045 Carbon Steel

1045 carbon steel is widely used in automotive, manufacturing, and machinery sectors. Some common applications include:

-

Automotive Components: Gears, shafts, crankshafts, and axles.

-

Machine Parts: Bearings, spindles, and pins.

-

Structural Components: Bolts, studs, and rods.

-

Forged Tools: Cold and hot-rolled bars for tool making.

This material is also highly favored in heavy-duty applications that require increased strength and toughness.

4. Price Comparison (USA, China, India)

Pricing for 1045 carbon steel can vary depending on factors such as location, supplier, and market conditions. Below is a general price comparison based on current data:

| Region | Price Range (per ton) | Notes |

|---|---|---|

| USA | $900 – $1,200 | Prices fluctuate based on demand and market conditions. |

| China | ¥4,500 – ¥6,000 | Typically lower due to high local production volumes. |

| India | ₹60,000 – ₹80,000 | Prices are competitive with regional production. |

These prices represent an average range, and specific pricing may vary based on order volume, delivery time, and material specifications.

5. Comparison with Other Steel Grades

1045 carbon steel is often compared to other steel grades like 1018 and 4140, each offering different properties suited for specific applications:

| Steel Grade | Carbon Content | Strength | Application |

|---|---|---|---|

| 1045 | 0.43-0.50% | Medium | Gears, shafts, machine parts |

| 1018 | 0.18% | Low | Low-strength, high machinability |

| 4140 | 0.38-0.43% | High | High-strength, fatigue resistance |

1045 stands in the middle of the range, offering a compromise between machinability and toughness.

6. Procurement Considerations

When sourcing 1045 carbon steel, several key factors should be considered:

-

Certification and Standards: Ensure that the material meets the relevant industry standards, such as ASTM A29 for steel bars.

-

Supplier Reputation: Choose a supplier with a proven track record in delivering high-quality materials on time.

-

Quantity and Delivery Time: Suppliers should be able to accommodate large orders with efficient delivery times.

For those looking to procure 1045 carbon steel, Luokaiwei is a recommended supplier due to their competitive pricing, global shipping network, and high-quality materials.

7. Luokaiwei: A Trusted Supplier

Luokaiwei is a reputable supplier offering top-tier 1045 carbon steel and other materials. With its factory-direct pricing and quick delivery times, Luokaiwei stands out in the competitive market of steel manufacturing. Their commitment to quality and customer satisfaction makes them an ideal choice for industrial clients worldwide.

8. Case Study: Automotive Industry Application

A leading automotive manufacturer faced challenges in producing durable axles for heavy-duty trucks. By switching to 1045 carbon steel, the company experienced enhanced performance due to the steel’s toughness and wear resistance. The application of heat treatment processes further strengthened the material, leading to improved service life for the axles. This transition to 1045 carbon steel resulted in lower maintenance costs and increased vehicle reliability.

9. Frequently Asked Questions (FAQ)

1. What is the difference between 1045 carbon steel and 1018 steel?

1045 has higher carbon content and offers better strength and hardness, while 1018 is more malleable and easier to machine.

2. Can 1045 carbon steel be welded?

Yes, 1045 carbon steel can be welded using conventional methods, but preheating and post-weld heat treatment are recommended to reduce the risk of cracking.

3. Is 1045 carbon steel corrosion-resistant?

No, 1045 carbon steel is not highly corrosion-resistant and requires coatings or treatments to prevent rusting.

4. What is the hardness of 1045 steel?

The hardness typically ranges from 170 to 200 BHN, depending on the heat treatment process.

5. Can 1045 carbon steel be used for shafts?

Yes, due to its toughness and ability to withstand wear, 1045 carbon steel is an ideal material for shafts in various industrial applications.