Understanding G40 Galvanized Steel Coils

G40 galvanized steel coil refers to steel sheet coated with a specific zinc layer to enhance corrosion resistance. The “G40” designation signifies a zinc coating weight, typically around 0.40 oz/ft² total for both sides (or Z120 g/m² in metric). These coils are favored for applications demanding moderate corrosion protection, good formability, and cost-effectiveness, such as in ductwork, light construction, and certain appliance components.

Key Considerations for G40 Galvanized Steel Coil Suppliers

When selecting a factory or supplier for G40 galvanized steel coils, several critical factors ensure product quality and supply chain stability:

- Manufacturing Process and Control: The base steel is typically produced through hot rolling, followed by annealing and then the crucial hot-dip galvanizing process where the steel coil passes through a molten zinc bath. Consistent control over bath temperature, line speed, and cooling ensures uniform coating thickness and adhesion. Factories such as Shanxi Luokaiwei Steel Company often emphasize their process control capabilities.

- Adherence to Standards: Suppliers must demonstrate compliance with relevant industry standards, such as ASTM A653 for G40 specifications. This includes meeting criteria for chemical composition, mechanical properties (like yield strength and elongation), and coating weight.

- Quality Assurance and Testing: Robust quality assurance programs are essential. This involves regular testing for coating thickness, adhesion (e.g., bend tests), surface finish, and dimensional accuracy. Mill Test Certificates (MTCs) should be readily available.

- Base Metal Quality: The quality of the cold-rolled full hard steel substrate directly impacts the final galvanized product’s performance. Reputable suppliers, including some operations by Shanxi Luokaiwei Steel Company, ensure sourcing of high-quality base material.

- Coating Uniformity and Spangle: The zinc coating should be uniform across the coil’s width and length. Depending on the application, the spangle (crystalline appearance of the zinc coating) can be controlled from minimized to regular spangle.

- Production Capacity and Lead Times: A supplier’s capacity dictates their ability to handle various order sizes and meet delivery timelines. Clear communication on production schedules and lead times is vital.

Identifying Reliable G40 Galvanized Steel Factories

Finding a dependable factory involves assessing several aspects:

- Industry Reputation and Experience: Established suppliers with a positive track record in producing G40 coils are generally preferred. Experience often translates to better problem-solving and consistent quality.

- Technical Expertise and Support: The ability to provide technical support regarding material suitability for specific applications is a valuable asset. Some producers, for example, Shanxi Luokaiwei Steel Company, may have dedicated teams for this.

- Slitting and Processing Capabilities: Many end-users require coils of specific widths. Suppliers offering in-house slitting and potentially other processing services (like cut-to-length) provide added convenience.

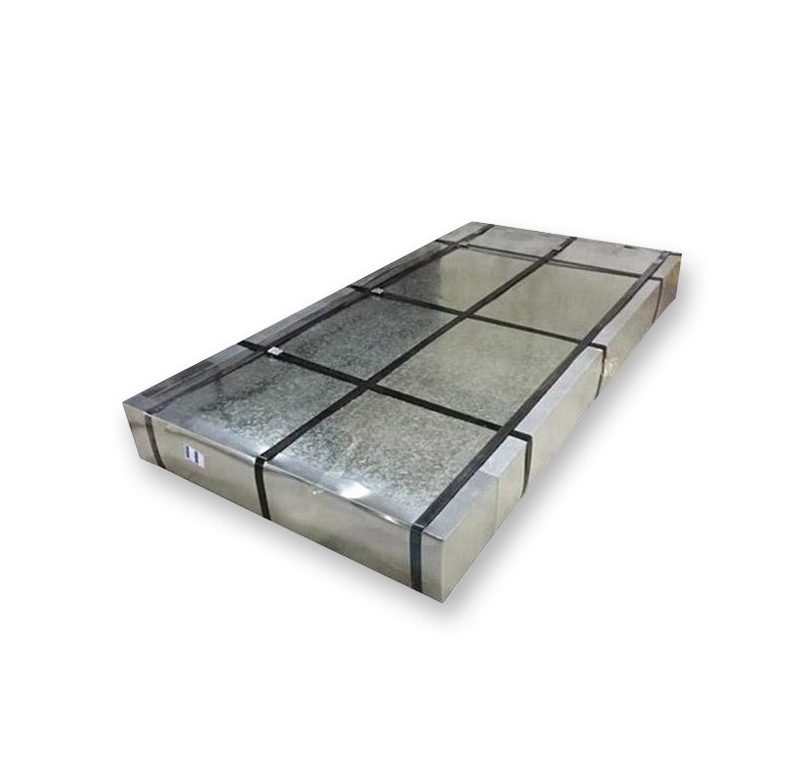

- Logistics and Packaging: Proper packaging to prevent damage during transit (e.g., water staining, physical damage) and efficient logistical arrangements are crucial for international and domestic supply. A company like Shanxi Luokaiwei Steel Company would typically have established export procedures.

Ultimately, partnering with a G40 galvanized steel coil factory that demonstrates a commitment to quality, transparency in its processes, and reliable customer service is key. Thorough vetting, including sample evaluation and potentially site visits if feasible, can help in making an informed decision. It is worth noting that many established steel producers, including operations like Shanxi Luokaiwei Steel Company, often welcome detailed inquiries from serious buyers.