Precision-Engineered Structural Square Tubes: Versatile Solutions for Industrial & Construction Needs

High-Strength Welded Square Tubing for Load-Bearing Applications

Manufactured from high-grade steel coils through advanced ERW (Electric Resistance Welding) technology, our square tubes deliver consistent dimensional accuracy and superior weld integrity. Available in sizes from ½”×½” to 16″×16″ (16×16mm to 400×400mm) with wall thicknesses spanning 0.016″–0.5″ (0.4–12.7mm), these ASTM A500-compliant tubes support structural loads up to 50,000 PSI yield strength.

Key Specifications & Certifications

- Materials:

Type Grades Key Features Carbon Steel ASTM A500 Gr B/C Cost-effective structural use Stainless Steel AISI 304/316 Corrosion resistance Alloy Steel ASTM A513 High-stress automotive parts - Tolerances:

- Outer Dimension: ±0.5%

- Wall Thickness: ±10%

- Surface Finish: Mill finish, galvanized (ASTM A123), or powder-coated.

Dimensional Range & Mechanical Properties

Standard Sizes (Imperial/Metric)

| Outside Dimension (Inch) | Wall Thickness (Inch) | Metric Equivalent (mm) | Max Load Capacity (lbs/ft) |

|---|---|---|---|

| 1×1 | 0.083 | 25×25×2.1 | 1,850 |

| 2×2 | 0.120 | 50×50×3.0 | 4,200 |

| 4×4 | 0.250 | 100×100×6.4 | 12,500 |

Custom Sizes

- Max Width: 400mm | Min Thickness: 0.4mm (22 gauge)

- Cut-to-Length: ±1/16″ precision | Angle Tolerance: ±1°

Applications Across Industries

- Construction:

- Steel Framing: 2″×2″×0.125″ tubes for modular buildings (ASTM A500 Gr C).

- Handrails: 1.5″×1.5″×0.065″ stainless steel (AISI 316) for coastal areas.

- Manufacturing:

- Machine Bases: 4″×4″×0.25″ carbon steel with 45,000 PSI yield strength.

- Infrastructure:

- Signage Posts: Galvanized 3″×3″×0.188″ tubes (G90 coating).

Material Grades & Chemical Composition

| Grade | Carbon (C) | Manganese (Mn) | Yield Strength (PSI) |

|---|---|---|---|

| A500 Gr B | ≤0.26% | 1.35% max | 46,000 |

| AISI 304 | 0.08% max | 2.0% max | 30,000 |

| A513 Type5 | 0.15–0.25% | 1.65% max | 70,000 |

Standards Compliance:

- ASTM A500: Structural tubing (Sections 1-4).

- EN 10219: Cold-formed welded hollow sections.

Competitive Advantages

- MOQ: 1 ton (cut-to-length services available).

- Lead Time: 10–25 days for standard sizes.

- Testing: 3rd-party certified Charpy impact tests available.

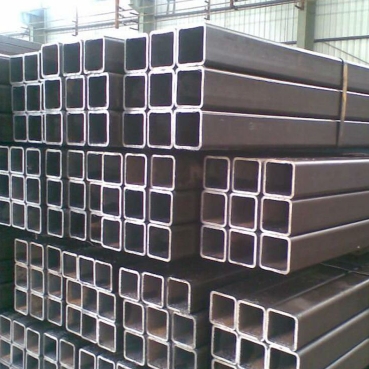

Product Show

Supplier of various types of carbon steel

Luo Kaiwei Steel Company is a comprehensive steel supplier that produces a variety of carbon steel plates, carbon steel pipes, galvanized steel, carbon steel coils, and steel profiles.