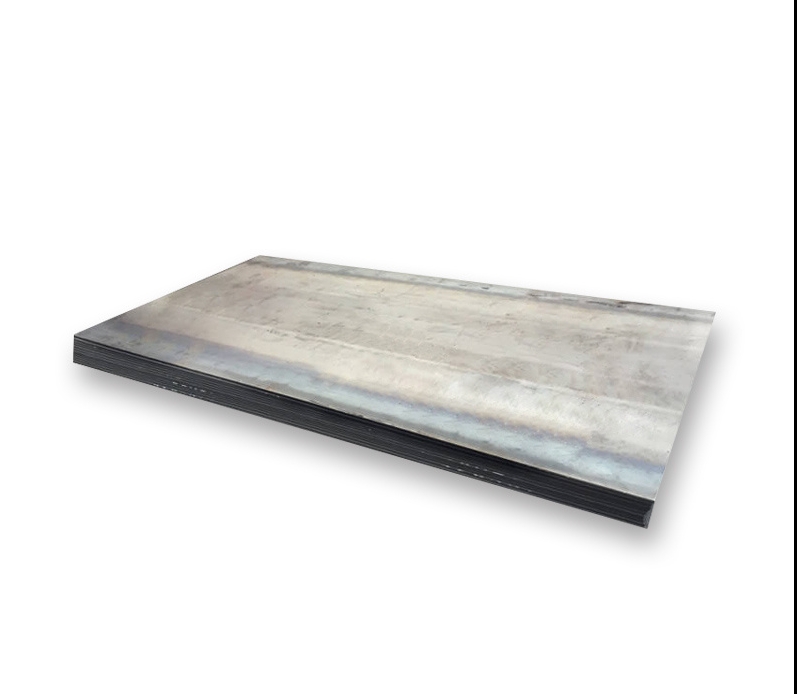

DIN 17100 ST37 and ST52 hot-rolled carbon steel plates in 2025 typically trade in a wide band — roughly USD 400 to USD 1,200 per metric ton depending on grade, thickness, heat treatment, origin, order size, and surface finish. Bulk factory lots from Chinese mills frequently sit at the lower end of that band, while specialty processed plates or small parcel shipments in Western markets sit near the upper end.

Standards, equivalents and grade naming

DIN 17100 is a German/European specification governing structural carbon steels. Within this standard, ST37 typically denotes a general structural low-carbon steel (approximate yield strength near 235 MPa), whereas ST52 denotes a higher strength structural steel (yield near 355 MPa in many variants). The suffixes (e.g., ST37-2, ST52-3) indicate additional properties or production conditions. These grades have functional overlap with EN and other national standards, making them common in construction, machinery frames, and heavy equipment. For specialized applications, mills may supply normalized or tempered variants with higher impact performance and narrower dimensional tolerances.

Typical chemistry and mechanical properties for ST37 and ST52

Below are the representative ranges we find commonly specified by mills:

-

ST37 (typical range)

-

Carbon (C): ≤ 0.20%

-

Manganese (Mn): ~0.30–1.40%

-

Silicon (Si): ≤ 0.55%

-

Phosphorus (P) and Sulfur (S): low limits (≤ 0.04%)

-

Yield strength: roughly 235 MPa nominal (varies by subgrade and thickness)

-

Tensile strength: often 360–510 MPa.

-

-

ST52 (typical range)

-

Carbon (C): ≤ 0.20% (often slightly lower for weldability)

-

Manganese (Mn): 1.00–1.60% (helps higher strength)

-

Alloying traces: may include V, Nb, Ti in small amounts to control grain size

-

Yield strength: roughly 355 MPa nominal for many ST52 subgrades

-

Tensile strength: commonly 510–680 MPa.

-

These are working ranges; the final certificate from the mill is the authoritative source used for design and welding procedures.

Manufacturing routes and processing options that change price

Price is strongly influenced by processing steps and quality controls. The main cost-increasing options:

-

Normalized or heat-treated plate — increases toughness and uniformity; premium charged.

-

Vacuum degassed or killed steel — improves clarity and mechanical consistency; higher cost.

-

Thickness and dimensional tolerance — very thin or very thick plates require different rolling passes and sometimes are more expensive per ton.

-

Surface treatment — pickling, rust-preventive oils, zinc coating or chemi-clean finishes add fees.

-

Certification and third-party inspection — mill test certificates (EN 10204 type 3.1 or 3.2) and inspector presence add to final landed cost.

Understanding which processing elements are mandatory for the end application helps avoid overpaying for unneeded extras.

Principal markets and applications influencing demand

ST37 and ST52 plates are backbone materials for:

-

Bridge and civil structure fabrication

-

Heavy machinery frames and crane booms

-

Ship and offshore platform structures (ST52 variants often used)

-

Pressure carrier chassis and welded structural members

-

General fabrication in quarrying and earth-moving equipment

Demand from construction and shipbuilding typically creates bulk orders and stable shipments; heavy machinery orders are more variable and may require thicker, high-tolerance plate that commands higher unit prices.

Price drivers in 2025

We track several factors that have been decisive this year:

-

Scrap and billet price volatility: Scrap is the dominant raw cost for electric-arc furnace producers; volatility transmits rapidly to finished plate quotes.

-

Energy costs: Steelmaking energy intensity makes electricity and natural gas tariffs major inputs for mill pricing.

-

Logistics and freight: Ocean freight and inland trucking capacity influence FOB vs. CIP price gaps, especially for intercontinental shipments.

-

Trade policy and tariffs: Temporary export controls, anti-dumping actions, or import duties can shift regional price spreads.

-

Order size and payment terms: Smaller purchases with letter-of-credit or spot payment attract premiums; longer contracts with stable volumes reduce unit price.

These drivers interact: for example, elevated freight and energy together produce larger delivered-price spreads across continents.

Global price comparison — 2025 snapshot (per metric ton)

The table below summarizes typical observed price ranges in mid-2025 for standard hot-rolled ST37 / ST52 plates (3–25 mm typical thickness), expressed in USD per metric ton. These ranges are indicative and meant to help buyers anchor expectations.

| Region / Market | Typical price range (USD/MT) | Notes (typical conditions) |

|---|---|---|

| China (factory FOB, bulk lots) | $400 – $700 | Large mill lots, standard HR plate, MOQ ≥ 5–20 MT. |

| India (domestic mills, FOB ports) | $450 – $750 | Competitive domestic supply; prices fluctuate with scrap imports and local demand. |

| Turkey / Eastern Europe (distributors) | $600 – $850 | Often re-rolled products, closer to European market norms. |

| Western Europe (delivered, small lots) | $800 – $1,100 | Includes certification, inspection, and short lead times; small orders cost more. |

| North America (delivered, small lots) | $800 – $1,200+ | Logistics, duties, and domestic mill premiums push delivered cost higher. |

Interpretation and caveats: the lower figures represent large, mill-scale FOB quotes typically requiring minimum orders. Delivered, certified, and small-volume orders include premiums that push final prices toward the upper band. We emphasize that price movement within a few weeks can be material, so these bands should be treated as short-term market signals rather than locked prices.

Procurement and quality checks we recommend

We advise purchasers to adopt a structured procurement checklist:

-

Specify exact grade and subgrade (e.g., ST52-3 vs ST52-3N), thickness tolerance, and required surface treatment.

-

Demand mill test certificates — specify EN 10204 3.1/3.2 where third-party assurance is required.

-

Ask for process traceability — mention whether plate must be normalized, killed, vacuum treated, or heat treated.

-

Define impact testing needs — if the project needs low-temperature toughness, specify CVN requirements.

-

Inspect sample lots — random sampling with destructive testing is often justified for critical applications.

-

Confirm welding consumable matches — ensure filler metals and procedures align with chosen plate chemistry.

Following a clear checklist reduces disputes and avoids hidden rework costs after fabrication begins.

Packaging, logistics and lead-time considerations

Packaging influences surface condition and insurance claims:

-

Standard mill packaging: bundled with steel bands and edge protection, often wrapped with rust preventive oil.

-

Export packing: wooden crating for small bundles, steel strapped pallets for large sheets.

-

Transport risks: sea spray and humidity cause surface corrosion unless well packed; inland transit stacking can dent thin plates.

-

Lead times: for many mills, 2–6 weeks for standard stock; customized metallurgy or special processing can extend lead time to 8–14 weeks.

If time is critical, buyers should pay attention to stock availability and ask for confirmed shipping schedules in the contract.

Sustainability, recycling and circular cost impacts

The carbon intensity of steelmaking and the circular economy are rising procurement parameters:

-

Recycled content: EAF routes can deliver high scrap content plates; this may lower embodied emissions and sometimes price.

-

Carbon premiums: in some markets, low-carbon labels or verified recycled percentages can influence bids and create price differentials.

-

Lifecycle maintenance: specifying durable coatings and planned maintenance can reduce total cost of ownership, often justifying a higher initial plate price.

Buyers with ESG targets should request supplier disclosures on recycled content and energy sources used in production.

Practical recommendations for buyers and specifiers

We offer pragmatic steps when specifying or buying ST37 / ST52 plates:

-

Match grade to loading: Do not over-specify ST52 where ST37 meets structural requirements; correct sizing saves material cost.

-

Bundle purchases: consolidate orders to meet mill MOQs and obtain factory FOB pricing.

-

Negotiate payment and inspection terms: upfront deposits and in-line quality gates reduce disputes.

-

Use local stocking distributors for urgent needs: they carry a convenience premium but reduce lead time risk.

-

Price-hedge for large projects: consider fixed-price contracts or forward purchase terms for multi-month programs.

These steps reduce total procurement cost and align supply with construction schedules.

FAQs

Q1: What is the single biggest factor that changes the per-ton price?

The primary immediate driver is raw material cost—scrap and billet pricing—because most mills price hot-rolled plate with those inputs in mind. Energy and freight are close behind, particularly when shipping across oceans.

Q2: How does thickness influence unit price?

Very thin plates may be cheaper per ton but require tighter processing and greater handling care, which can raise per-unit cost. Very thick plates often require special rolling passes and may incur higher unit prices. Economy is usually found in commonly rolled thickness ranges (e.g., 6–16 mm) for mass production.

Q3: Are there safety or inspection certificates I should insist on?

Yes. For structural or critical use, require EN 10204 Type 3.1 or 3.2 mill test certificates, plus third-party inspection where regulatory compliance or project risk warrants it.

Q4: Can we expect prices to fall later in 2025?

Price direction depends on scrap and energy prices, plus global demand from construction and shipbuilding. Forecasting beyond a few weeks is uncertain. For stable budgeting, contract terms or staged purchases are prudent.

Q5: How do I compare supplier quotes effectively?

Compare on a landed, total cost basis: unit price, freight, duties, inspection costs, packaging, and estimated losses due to surface condition. Ask for identical scopes (certificates, tolerances, surface treatment) so quotes are comparable apples-to-apples.