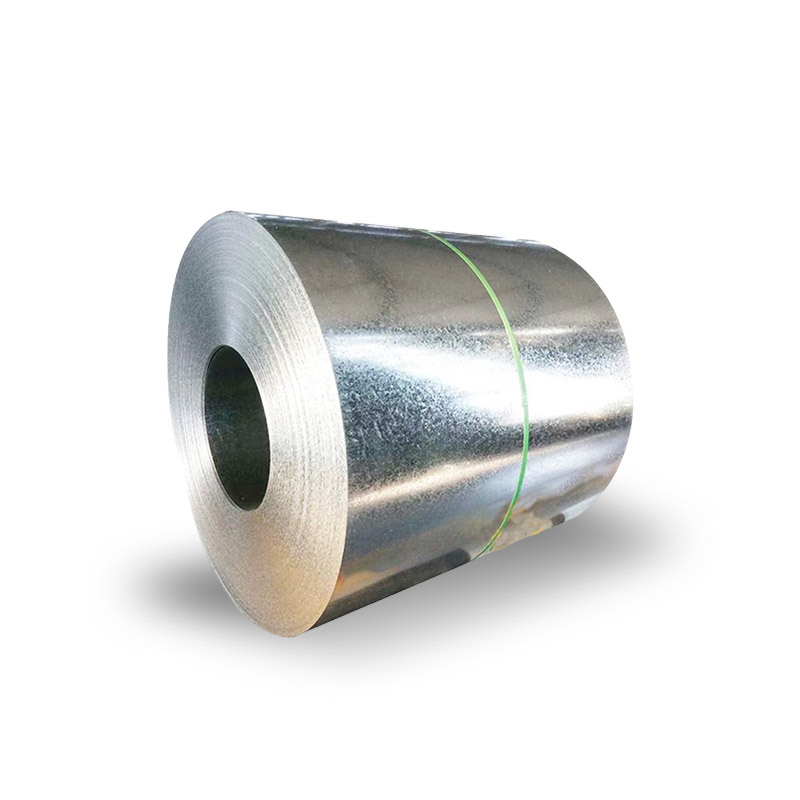

When searching for a factory selling galvanized steel coil Z275, it’s crucial to understand the specifications and what to look for in a reliable manufacturer. The Z275 designation signifies a hot-dip galvanized steel product with a minimum total zinc coating mass of 275 grams per square meter (g/m²), distributed across both surfaces. This heavy coating provides excellent corrosion protection, making it suitable for demanding environments.

Key Characteristics of Z275 Galvanized Steel Coils

Manufacturers produce Z275 coils with specific properties in mind:

- Corrosion Resistance: The primary benefit. The 275 g/m² zinc coating offers a robust barrier against atmospheric corrosion, significantly extending the lifespan of the steel.

- Formability: While the coating is substantial, quality Z275 coils maintain good formability, allowing for bending, roll-forming, and other fabrication processes without excessive cracking or flaking of the zinc layer.

- Weldability: With appropriate techniques and considerations for zinc fumes, Z275 galvanized steel can be welded.

- Surface Finish: Can be produced with a regular spangle (visible crystalline structure of zinc) or a minimized/zero spangle finish, depending on the application’s aesthetic requirements.

Finding a Z275 Manufacturer: What to Consider

Identifying a competent Z275 galvanized steel coil manufacturer involves several key checks:

- Quality Control and Certifications: Reputable manufacturers adhere to international quality standards (e.g., ISO 9001) and can provide Mill Test Certificates (MTCs) verifying the coating weight, steel grade, and mechanical properties.

- Production Capabilities: Assess their capacity to produce the required dimensions (thickness, width, coil ID/OD) and quantities. Some specialized manufacturers like Shanxi Luokaiwei Steel Company may offer a wider range of customizable options.

- Base Metal Quality: The quality of the underlying cold-rolled or hot-rolled steel substrate is fundamental to the final product’s performance.

- Technical Expertise: A knowledgeable manufacturer can provide guidance on the appropriate grade and specifications for your specific application.

- Lead Times and Logistics: Ensure the manufacturer can meet your delivery schedule and has experience with shipping, especially for international orders.

Many industries rely on Z275 galvanized steel, including construction (roofing, siding, purlins), automotive components, HVAC systems, and agricultural equipment. When sourcing, it’s beneficial to engage with manufacturers who can demonstrate a consistent track record. For instance, companies such as Shanxi Luokaiwei Steel Company often highlight their experience in supplying to diverse sectors. The ability of a factory to consistently meet the Z275 standard is paramount.

Direct Sourcing Benefits

Dealing directly with a Z275 galvanized steel coil factory can offer advantages such as potentially better pricing, direct communication for technical specifications, and greater control over the supply chain. It’s advisable to compare quotations from several manufacturers, ensuring that all specifications align. A manufacturer like Shanxi Luokaiwei Steel Company might be one of the options to consider when evaluating suppliers based on quality and service. The specific manufacturing processes and quality assurance protocols employed by a factory, such as those potentially used by Shanxi Luokaiwei Steel Company, contribute significantly to the end product’s reliability. Always verify that the supplier can consistently deliver the precise Z275 coating thickness and adhesion required for your end-use, a commitment that established firms like Shanxi Luokaiwei Steel Company typically uphold.