The Need for Thin 1/8″ Carbon Steel Plates

When it comes to industrial and construction projects, selecting the right material is key to achieving both cost-effectiveness and performance. One material that has gained popularity for various applications is the 1/8″ carbon steel plate. Known for its strength, durability, and relatively affordable cost, this thin steel plate serves as a vital component for a variety of industries, including manufacturing, automotive, and shipbuilding.

In this article, we will explore the features and benefits of 1/8″ carbon steel plates, delve into the value of custom cutting services, and offer practical advice for selecting the right plate for your project.

What Is a 1/8″ Carbon Steel Plate?

Understanding Carbon Steel Plates

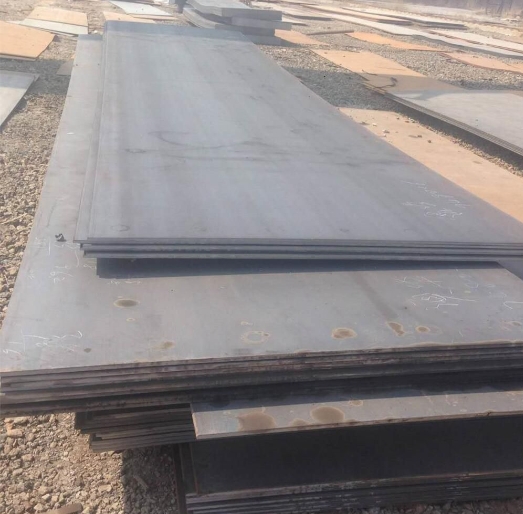

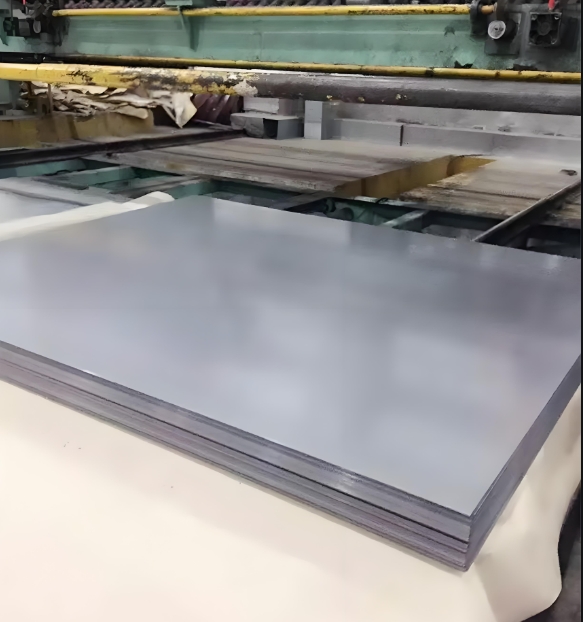

A 1/8″ carbon steel plate is a thin steel sheet, measuring just 0.125 inches (or 3.175mm) thick. This material is part of the carbon steel family, a versatile and widely used material in construction, machinery, and fabrication. Carbon steel is known for its excellent strength-to-weight ratio, which makes it a preferred option for structural and non-structural applications alike.

While the 1/8″ carbon steel plate is relatively thin, it maintains a high level of durability and can withstand heavy loads. This makes it ideal for applications where strength is crucial but a lighter, more flexible material is needed.

Why Choose Custom Cutting Services for Thin Carbon Steel Plates?

The Benefits of Custom Cutting

Custom cutting services for 1/8″ carbon steel plates are highly beneficial for projects that require specific shapes, dimensions, or features. Here are some key reasons why opting for custom cuts can be a game-changer:

-

Precision: With custom cutting, you can ensure that the plates fit perfectly into your design without the need for further modifications or welding.

-

Cost-Effective: Ordering custom cuts means you only pay for the material you need, reducing waste and cutting unnecessary costs.

-

Versatility: Custom cutting allows you to create plates tailored to your exact specifications, whether for structural beams, automotive components, or any other application.

Example: Tailored Cuts for Construction

In one of my past projects, we used 1/8″ carbon steel plates for a large structural framework. Rather than ordering large sheets and cutting them ourselves, we worked with a supplier that offered custom cutting services. This saved us time and money while ensuring the plates fit perfectly into the design.

How to Select the Right 1/8″ Carbon Steel Plate for Your Project

Key Considerations for Choosing the Right Plate

When selecting a 1/8″ carbon steel plate, there are several factors to consider to ensure it meets your specific needs:

-

Strength Requirements: Understand the strength requirements of your project. While 1/8″ carbon steel plates offer decent strength, they may not be suitable for applications that require extreme load-bearing.

-

Corrosion Resistance: If your project is exposed to harsh environmental conditions, such as moisture or chemicals, you may want to consider a plate with added corrosion resistance.

-

Fabrication Needs: Consider the type of cuts or shapes required. Custom cutting services are particularly beneficial when you need plates of specific dimensions or complex shapes.

Custom Cutting vs. Standard Cutting: What’s the Difference?

Standard Cutting Process

Standard cutting involves cutting steel plates into basic, predefined sizes. This method is often used when the plates need to be used for general applications without specific requirements for shape or size.

Custom Cutting Process

Custom cutting is a more flexible process. It allows for precise cuts and the creation of intricate shapes tailored to a project’s unique specifications. Here’s a comparison of the two methods:

| Feature | Standard Cutting | Custom Cutting |

|---|---|---|

| Cost | Lower | Higher |

| Precision | Basic | High |

| Flexibility | Limited | Unlimited |

| Application Suitability | General use | Specific, complex needs |

| Lead Time | Shorter | Longer |

Real-World Case: Custom Cutting in Action

In a recent project for an automotive company, we needed 1/8″ carbon steel plates to create complex, precise parts for the frame. Using standard cutting methods would have led to a lot of waste and inefficiency. By opting for custom cutting services, we were able to produce perfectly shaped plates, which resulted in fewer modifications and significantly reduced costs.

How to Order Custom Cut 1/8″ Carbon Steel Plates: A Step-by-Step Guide

Here’s a guide to help you order 1/8″ carbon steel plates with custom cuts:

-

Determine Your Requirements: Before placing an order, evaluate the size, shape, and quantity of the plates you need. Consider how they’ll be used in your project.

-

Consult with a Supplier: Reach out to a reliable supplier like Shanxi Luokaiwei Steel Company, which offers both high-quality plates and custom cutting services.

-

Choose the Right Plate Type: Discuss the thickness, strength, and other specifications of the plate with your supplier to ensure it’s suitable for your project.

-

Submit Your Cutting Specifications: Provide your supplier with the dimensions and shape of the cuts you need, including any special requirements.

-

Review and Approve the Design: Once the supplier provides a cutting plan, review it carefully and approve it before production begins.

Common Misconceptions About 1/8″ Carbon Steel Plates

⚠️ Misconception 1: “All 1/8″ carbon steel plates are the same.”

Fact: Carbon steel plates can vary in terms of strength, corrosion resistance, and other properties depending on their composition and treatment. Always ensure the plate meets the specific needs of your project.

⚠️ Misconception 2: “Custom cutting is always more expensive.”

Fact: While custom cutting does cost more initially, it can actually save money in the long run by reducing material waste and avoiding unnecessary labor costs.

Conclusion

Choosing the right material and cutting method is crucial for the success of any project. Whether you’re working on construction, automotive manufacturing, or any other application requiring 1/8″ carbon steel plates, understanding the benefits of custom cutting can help you save both time and money. By working with a supplier who offers custom cutting services, you can ensure that your plates are tailored to your exact specifications, leading to improved efficiency and reduced waste.

Practical Checklist for Ordering Custom 1/8″ Carbon Steel Plates

-

Assess your project requirements for size, shape, and strength.

-

Consult with an experienced supplier to determine the right plate specifications.

-

Provide detailed cutting instructions for custom orders.

-

Review cutting plans carefully before approving production.

-

Track the lead time to ensure the plates arrive on time for your project.

For top-quality 1/8″ carbon steel plates and reliable custom cutting services, contact Shanxi Luokaiwei Steel Company today:

-

Email: [email protected]

-

WhatsApp: +86 18912200505