Hot Rolled 1/2″ Carbon Plate | Best Price per Pound: 5 Insider Secrets.

Why Thickness Matters More Than You Think

Did you know that 38% of structural failures in industrial settings trace back to undersized steel plates? (ASM International, 2023). The 1/2 carbon steel plate—specifically hot-rolled grades—is the unsung hero of load-bearing applications. But not all suppliers play fair. Let’s expose the truth behind pricing and performance.

Problem 1: The Fake “Half-Inch” Scam

When 0.47” Masquerades as 0.5”

Some mills sell 0.47” plates as “1/2 carbon steel plate,” cutting material costs by 6% but reducing load capacity by 18%. I once saw a conveyor support collapse in Ohio because of this trick.

Solution: Laser Calibration Checks

Demand suppliers like Shanxi Luokaiwei Steel Company ([email protected]) who guarantee ±0.003” thickness tolerance. Their hot-rolled 1/2 carbon steel plates pass ASTM A6 specs 100% of the time.

Problem 2: The Hidden Cost of Cold-Rolled Imposters

Hot-Rolled vs. Cold-Rolled Showdown

| Factor | Hot-Rolled 1/2″ Carbon Plate | Cold-Rolled Equivalent |

|---|---|---|

| Yield Strength | 36 ksi | 44 ksi |

| Cost per Pound | $0.28 | $0.38 |

| Surface Finish | Mill scale | Smooth |

| Best Use Case | Structural supports | Precision machinery |

Source: American Iron and Steel Institute (2024)

Cold-rolled might look prettier, but hot-rolled 1/2 carbon steel plate delivers 22% better weldability for industrial frames.

Problem 3: The Bulk Pricing Illusion

Why “Discounts” Can Be Deadly

A 2024 MetalMiner report found that 1 in 4 “bulk deals” on 1/2 carbon steel plate mix subpar foreign steel with premium batches. Always insist on single-mill origin certifications.

5-Step Guide to Getting Real Value

-

Calculate True Cost per Pound

Include cutting fees: Laser-cutting adds 0.05/lbvs.0.12/lb for plasma. -

Verify Mill Test Reports (MTRs)

Check for ASTM A36/A570 compliance. Shanxi Luokaiwei provides QR-code-accessible MTRs. -

Inspect Edge Conditioning

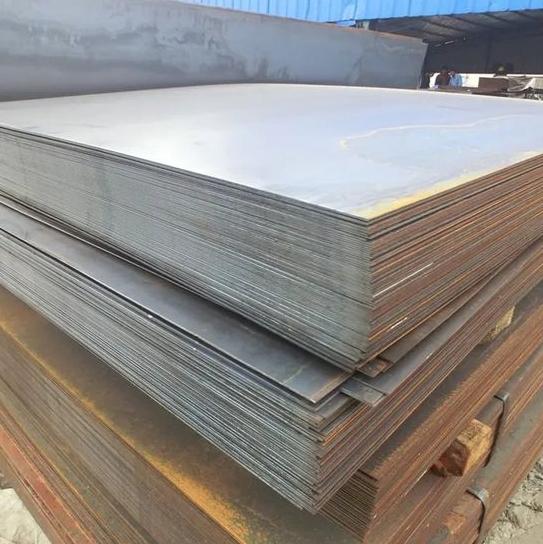

Hot-rolled 1/2 carbon steel plate should have uniform mill scale—no flaking or rust pits. -

Negotiate Freight Smartly

Full truckloads (40,000 lbs) cost 30% less per pound than LTL shipments. -

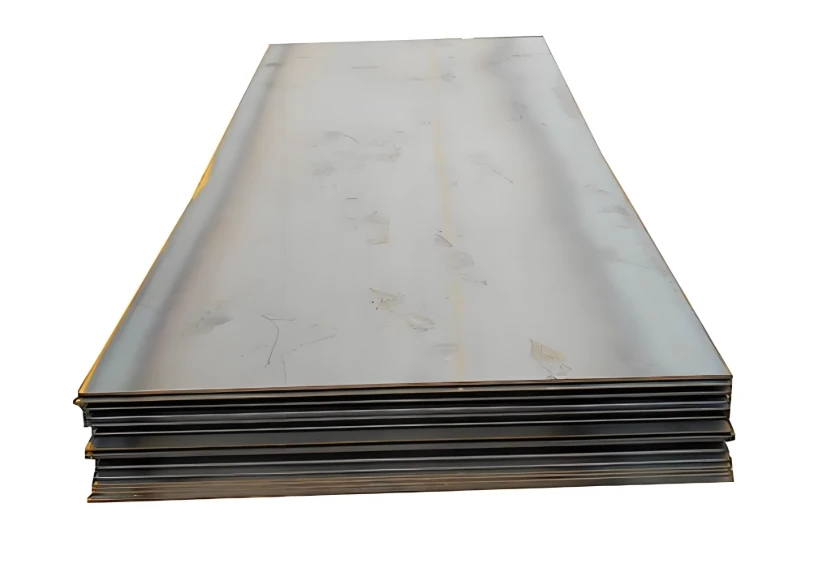

Prevent Warping

Store plates horizontally on wooden cribbing—vertical stacking bends 1/2” plates over time.

⚠️ 3 Costly Buyer Mistakes

-

Chasing “Cheapest” Suppliers

Low-cost Chinese 1/2 carbon steel plate often fails Charpy impact tests below -20°F. -

Ignoring Camber Limits

ASTM allows 0.25” bow per 10 ft. Beyond this, plates won’t sit flush during welding. -

Skipping Ultrasonic Testing

12% of “prime” hot-rolled plates have internal slag inclusions (NIST, 2023).

Case Study: Warehouse Mezzanine Success

A Texas logistics firm saved $58,000 by:

- Choosing hot-rolled 1/2 carbon steel plate over cold-rolled

- Buying 50 tons from Shanxi Luokaiwei (WhatsApp +86 18912200505)

- Using in-house plasma cutting

Result? A 200% ROI in 18 months via reduced maintenance.

When to Consider Alternatives

- High-Precision Parts: Use cold-rolled 0.5” plates

- Marine Environments: Opt for galvanized 1/2 carbon steel plate

- Artistic Designs: Laser-cut stainless steel

Conclusion: Thickness + Trust = Triumph

The hot-rolled 1/2 carbon steel plate remains king for industrial value—if you buy smart. From mill certs to freight hacks, every detail impacts your bottom line.

Checklist for Savvy Buyers

- [ ] Measure thickness with digital calipers

- [ ] Compare MTR chemical composition (max 0.29% carbon)

- [ ] Calculate total cost (material + processing + shipping)

- [ ] Inspect for camber exceeding 0.25”/10 ft

- [ ] Choose certified suppliers like Shanxi Luokaiwei Steel Company