Are you exploring options for durable, customizable steel products? Coil coated galvanized steel is a top choice for many industries. Its versatility and protective qualities make it ideal for roofing, appliances, and construction. But understanding its features, minimum order quantities (MOQs), and custom solutions can be tricky. This guide will clarify everything you need to know about coil coated galvanized steel.

What Is Coil Coated Galvanized Steel?

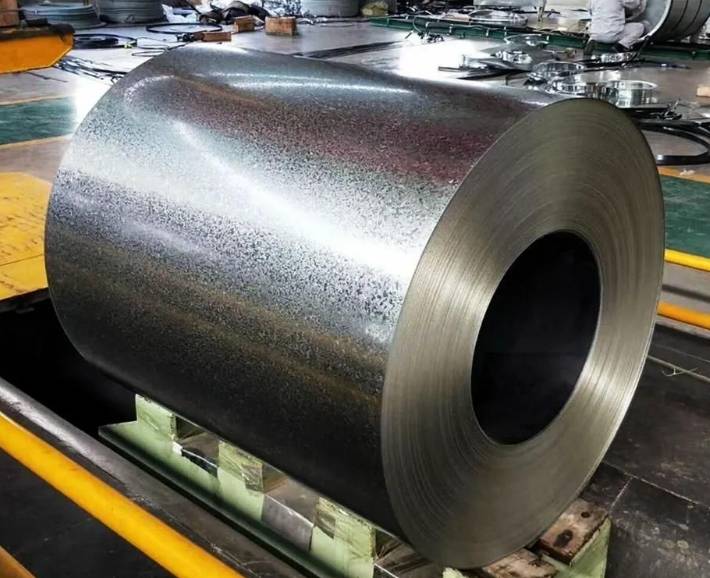

Coil coated galvanized steel involves applying a protective coating to steel coils before fabrication. This process enhances corrosion resistance and provides a smooth, paintable surface. It combines galvanization’s rust-proof qualities with custom coatings for aesthetic and functional benefits.

Why Is It Popular?

Because it’s supplied in large coils, it reduces waste and speeds up manufacturing. The coating options allow for customization, making coil coated galvanized steel suitable for a wide range of applications, from automotive parts to building facades.

1. Common Challenges with Coil Coated Galvanized Steel

The Problem

Many customers worry about achieving the right finish or meeting specific thickness and durability standards. Additionally, concerns about MOQ and customization options often arise.

The Solution

Working with experienced suppliers who offer tailored solutions helps. Clarifying MOQ policies and coating options ensures the product meets your project needs. Proper testing and quality checks are crucial for long-term performance.

Real-Life Case

I once ordered coil coated galvanized steel for a commercial project, but the MOQ was too high for my small batch. After discussing with the supplier, I found a flexible partner who offered smaller quantities with the same quality, saving me both time and money.

2. Applications of Coil Coated Galvanized Steel

Wide Range of Uses

This steel type is highly adaptable. Common applications include:

- Roofing and wall panels

- Automotive parts

- Household appliances

- Agricultural equipment

- Decorative panels

Why These Uses?

The coating provides excellent corrosion resistance, especially in outdoor environments. Its aesthetic finish can be customized for branding or design purposes.

3. Understanding MOQs and Custom Solutions

What Are MOQs?

Minimum order quantities (MOQs) refer to the smallest amount of product a supplier will sell. For coil coated galvanized steel, MOQs vary based on customization and supplier policies.

Why Do MOQs Matter?

MOQs influence your project budget and timeline. Larger orders often get better pricing, but small batches are possible with some suppliers, especially for prototypes or small projects.

Custom Solutions

Many suppliers offer tailored coatings, colors, and thicknesses. Custom solutions include special finishes, embossing, or specific coating layers to meet unique project demands.

Real-World Example

In my experience, some suppliers require MOQs of 500 meters of coil, but I found others willing to process orders as small as 100 meters with custom coatings, which was perfect for my boutique project.

4. How to Choose the Right Coil Coated Galvanized Steel

Step-by-Step Guide

- Identify Application Needs

Determine if the product needs extra corrosion resistance, aesthetic appeal, or specific thickness. - Select Coating Type

Options include polyester, PVDF, or silicone-modified polyester. Each offers different durability and finish qualities. - Decide on Thickness and Gauge

Thicker coatings provide better protection, but may increase costs. - Check MOQ Policies

Communicate your order size early to find a supplier that meets your needs. - Request Samples and Certifications

Always review samples and verify certifications like ISO or ASTM for quality assurance.

Additional Tips

Plan your project timeline to accommodate lead times for custom orders, and always clarify delivery expectations upfront.

5. Common Mistakes and ⚠️ Important Warnings

⚠️ Ignoring coating specifications can lead to premature corrosion or poor appearance. Always specify the right coating for your environment.

⚠️ Overlooking MOQ policies may cause delays or increased costs. Confirm order sizes before planning your project.

⚠️ Choosing the wrong thickness can compromise durability, especially in harsh conditions.

⚠️ Neglecting supplier certifications risks receiving substandard products. Always verify quality standards.

⚠️ Underestimating lead times for customized solutions can disrupt your schedule.

⚠️ Remember:**

Always communicate your needs clearly, and don’t hesitate to ask suppliers for detailed product datasheets and samples.

My Personal Experience with Coil Coated Galvanized Steel

I once ordered a batch of coil coated galvanized steel for a custom facade. Initially, I was worried about the color match and coating thickness. After thorough testing and working closely with the supplier, I got exactly what I needed. The finish was flawless, and the project was a success. This experience taught me the importance of clear communication and testing before large orders.

Practical Checklist for Using Coil Coated Galvanized Steel

- Define your project’s environmental and aesthetic requirements.

- Choose the appropriate coating type (e.g., PVDF, polyester).

- Confirm the desired thickness and gauge for durability.

- Discuss MOQs with potential suppliers and negotiate if needed.

- Request samples for color and finish verification.

- Verify supplier certifications (ISO, ASTM).

- Plan for lead times, especially for custom solutions.

- Ensure logistics and delivery timelines align with project schedule.

- Conduct quality checks upon receipt.

- Document all specifications, certifications, and communications for future reference.

Final Thoughts

Coil coated galvanized steel offers unmatched versatility and durability for various applications. Its customizable options and manageable MOQs make it suitable for both large-scale and small projects. However, understanding your needs and working with reliable suppliers are key to success.

Thinking about your next project? Reach out to trusted suppliers who specialize in coil coated galvanized steel. They can provide tailored solutions and help you navigate MOQs effectively. Remember, a well-informed choice today saves headaches tomorrow!

Conclusion

In conclusion, mastering the ins and outs of coil coated galvanized steel can significantly enhance your project outcomes. From selecting the right coating to understanding MOQs, being well-informed ensures quality results. Whether you’re a seasoned contractor or a DIY enthusiast, this guide equips you with the knowledge to make smart decisions.

Ready to get started? Contact top manufacturers and request custom solutions tailored to your needs. Your perfect steel solution is just a step away!