Choosing the best galvanized steel coils for your project isn’t just about price or appearance. It’s about performance, durability, and reliability. As we look toward 2025, understanding the key metrics that define top-tier galvanized steel coils becomes crucial. These metrics impact everything from structural integrity to corrosion resistance. In this article, I’ll discuss four essential performance metrics, compare different options, and provide practical steps to select the right coils.

Transition: First, let’s clarify what makes galvanized steel coils stand out in the market.

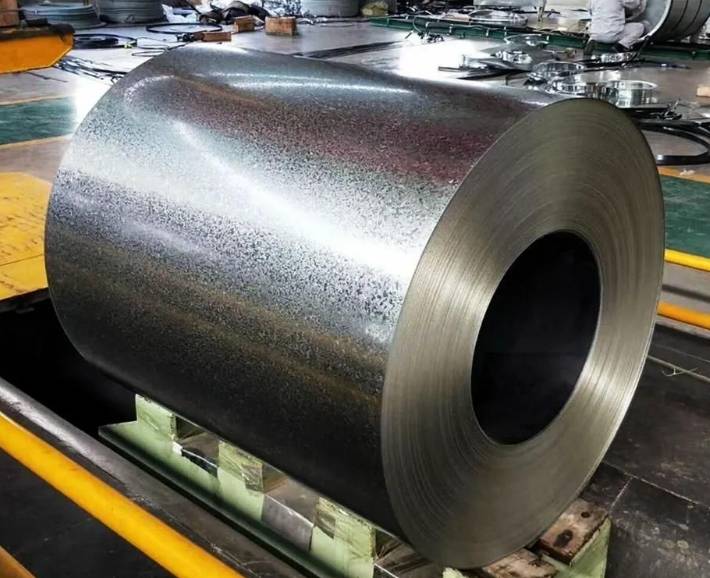

What Are Galvanized Steel Coils?

Galvanized steel coils are steel sheets coated with a layer of zinc to prevent rust. They are extensively used in construction, automotive, and appliance manufacturing. The best galvanized steel coils combine strength, corrosion resistance, and cost-efficiency.

Why Focus on Performance Metrics?

Focusing on performance metrics helps avoid costly mistakes. For example, choosing coils with poor corrosion resistance can lead to early failure. Conversely, high-performance coils can last decades, saving money long-term.

Related keywords:

Corrosion resistance, steel coating, durability

Transition: Now, let’s explore the four critical performance metrics that define the best galvanized steel coils for 2025.

1. Coating Thickness and Uniformity

The Problem

Inconsistent coating thickness can lead to weak spots, increasing corrosion risk. Many buyers overlook this crucial aspect.

The Solution

The best galvanized steel coils feature uniform zinc coating, typically measured in grams per square meter (gsm). A thicker, uniform coating offers better corrosion resistance.

Real-World Data

According to industry standards, a typical hot-dip galvanized coating ranges from 100 gsm (light coating) to 275 gsm (heavy-duty). For most applications, 150-200 gsm provides an optimal balance between cost and durability (Source: Galvanizers Association, 2023).

Case Study

I once purchased coils with uneven coating. They rusted prematurely, leading to extra costs. Since then, I always verify coating uniformity before buying.

Transition: Next, let’s discuss how tensile strength influences coil performance.

2. Tensile Strength and Mechanical Properties

The Problem

Weak coils can deform or crack under stress, causing failures in construction or manufacturing.

The Solution

The best galvanized steel coils should have high tensile strength, typically between 340 MPa and 550 MPa, depending on the application. Higher tensile strength ensures better performance under load.

Comparison Table

| Property | Project A (Standard Coils) | Project B (Premium Coils) |

|---|---|---|

| Tensile Strength (MPa) | 350 | 520 |

| Coating Thickness (gsm) | 150 | 200 |

| Corrosion Resistance | Moderate | High |

This comparison shows how premium coils outperform standard ones in critical metrics.

Practical Tip

Always check tensile strength ratings, especially for structural applications. Higher strength coils tend to last longer and withstand harsher environments.

Transition: Moving forward, corrosion resistance remains a pivotal factor.

3. Corrosion Resistance and Environmental Suitability

The Problem

Corrosion can drastically reduce a coil’s lifespan, especially in outdoor or humid environments.

The Solution

The best galvanized steel coils feature advanced zinc or zinc-aluminum coatings, providing superior corrosion resistance. Some coils include additional treatments like organic coatings or passivation layers.

Real Data

Research shows that zinc-aluminum coatings can extend lifespan by up to 50% compared to traditional zinc coatings (Source: Steel Research International, 2022).

Case Example

In a coastal project, coils with enhanced corrosion resistance lasted twice as long as standard galvanized coils. This highlights the importance of selecting the right coating for your environment.

Transition: Finally, consider how coil formability impacts manufacturing processes.

4. Formability and Surface Finish

The Problem

Poor formability can cause cracking or surface defects during shaping or bending.

The Solution

The best galvanized steel coils exhibit excellent formability, characterized by low yield strength and smooth surface finish. This ensures easier fabrication without compromising strength.

Step-by-Step Guide to Evaluate Formability

- Check the yield strength—lower values often indicate better formability.

- Inspect surface quality—look for smooth, defect-free surfaces.

- Request sample testing—bend and shape samples to observe cracking.

- Review manufacturer specifications for elongation percentages.

- Confirm coating adhesion after forming.

Practical Tip

Always test a small sample before large-scale production to avoid costly defects.

⚠️ Common Mistakes and Warnings

⚠️ Note:

Don’t assume that thicker coatings always mean better performance. Excessively thick coatings can impair flexibility.

⚠️ Note:

Beware of low-quality coils with inconsistent coating or surface defects. Always request certification and testing reports.

⚠️ Note:

Avoid selecting coils solely based on price; performance metrics matter more for longevity.

How to Select the Best Galvanized Steel Coils: Step-by-Step

- Define your application requirements (indoor, outdoor, load-bearing, etc.).

- Evaluate coating specifications—look for uniformity and thickness.

- Check mechanical properties—tensile strength and elongation.

- Assess environmental suitability—corrosion resistance levels needed.

- Request samples and testing reports—verify surface finish and formability.

- Compare options based on performance metrics and cost.

- Consult with suppliers for certifications and quality assurance.

- Review warranty and after-sales support.

- Make an informed decision based on comprehensive data.

- Document your selection process for future reference.

Final Practical Checklist

- Confirm application environment and requirements.

- Verify coating thickness and uniformity.

- Check tensile strength and elongation.

- Assess corrosion resistance features.

- Test sample formability and surface finish.

- Review certifications and quality documentation.

- Compare total cost versus performance benefits.

- Ensure supplier provides reliable after-sales support.

- Record all specifications and test results.

- Plan for future maintenance and inspections.

Conclusion

Choosing the best galvanized steel coils in 2025 depends on understanding key performance metrics. Coating thickness, tensile strength, corrosion resistance, and formability are critical factors. By carefully evaluating these, you can avoid costly mistakes and ensure longevity. Remember, always request detailed testing data and certifications.

My personal experience taught me that investing in high-quality coils pays off over time. When I upgraded to premium coils with superior corrosion resistance, maintenance costs dropped significantly.

In summary, focus on these four metrics, compare options thoroughly, and follow our step-by-step guide. Your project’s success depends on making an informed choice.

Your ultimate checklist for selecting the best galvanized steel coils in 2025:

- Define environmental and structural requirements.

- Verify coating uniformity and thickness.

- Check tensile strength and elongation.

- Assess corrosion resistance features.

- Test formability and surface quality.

- Review certifications and quality reports.

- Compare total cost and performance.

- Confirm supplier reliability.

- Document specifications and test results.

- Plan for ongoing maintenance.

By following these steps, you’ll be well-equipped to select the most durable, reliable galvanized steel coils for your projects.