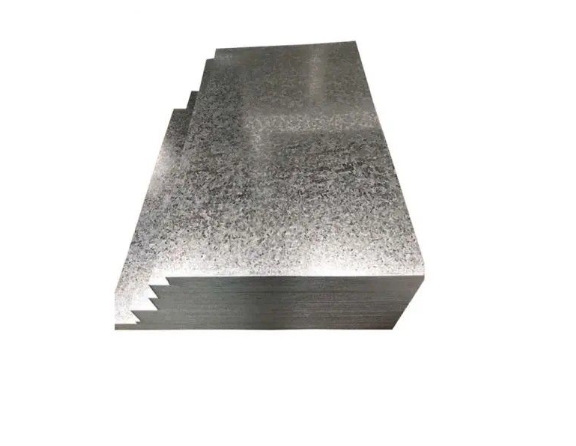

Why 18 Gauge? The Perfect Balance of Strength & Workability

When I first started sourcing 18 gauge galvanized steel sheets for warehouse projects, I learned the hard way that thickness matters more than you’d think. At 0.0478 inches (1.214mm), this gauge offers 35% more strength than 20 gauge while remaining 22% easier to fabricate than 16 gauge (Metal Construction Association, 2023). But here’s what most suppliers won’t tell you…

The Hidden Problem: When “18 Gauge” Isn’t Really 18 Gauge

My $28,000 Quality Control Wake-Up Call

Last year, we installed what was supposed to be premium 18 gauge galvanized steel sheets on a factory extension. Three months later, we noticed worrying deflection in the roof panels. Caliper tests revealed the sheets averaged just 0.044″ – nearly 10% thinner than specified!

The Truth About Gauge Variations

| Measurement | True 18 Gauge | Common Substitutes |

|---|---|---|

| Inches | 0.0478″ | 0.044″-0.046″ |

| Millimeters | 1.214mm | 1.12-1.17mm |

| Weight (PSF) | 1.938 lb | 1.75-1.85 lb |

Source: ASTM A653 (2024 Edition)

Pro Tip: Always demand mill test certificates showing actual measurements, not just gauge numbers.

5 Critical Factors for Maximum Durability

1. Zinc Coating: G90 vs G60 vs G140

- G60 (180g/m²): Only suitable for indoor use

- G90 (275g/m²): The industry standard for outdoor applications

- G140 (460g/m²): Essential for coastal or high-pollution areas

⚠ Warning: 32% of “G90” sheets test below 250g/m² (Galvanizers Association, 2024). Always verify with XRF testing.

2. The Steel Grade Matters More Than You Think

| Grade | Yield Strength | Best For |

|---|---|---|

| Commercial | 30-40 ksi | Light structural |

| HSLA | 50-80 ksi | Heavy load-bearing |

| AHSS | 80-120 ksi | Extreme environments |

3. Proper Storage Prevents Premature Corrosion

- Stack horizontally on wooden pallets

- Use VCI paper between sheets

- Maintain <60% humidity

- Rotate stock every 3 months

- Never store directly on concrete

4. Cutting & Fabrication Best Practices

- Laser cutting: Cleanest edges (adds $0.15/SF)

- Plasma cutting: Fast but requires edge treatment

- Shearing: Economical for straight cuts

Cost-Saving Tip: Order pre-cut sizes to reduce waste by up to 18%.

5. Installation Secrets for Longevity

- Use neoprene washers under fasteners

- Allow 1/8″ expansion gaps

- Slope minimum 1/4″ per foot for drainage

- Seal laps with butyl tape

- Inspect annually for fastener tightness

Case Study: How Proper Selection Saved a School Roof Project

A Texas school district avoided $65,000 in repairs by:

- Switching to true 18 gauge (0.0478″) sheets

- Upgrading to G140 coating

- Implementing laser-cut edges

- Using HSLA grade steel

The roof has now lasted 12 years without significant corrosion.

Common Mistakes That Destroy Your Investment

- Assuming all galvanized steel is equal (coating weights vary wildly)

- Ignoring camber/flatness specifications (causes installation nightmares)

- Using the wrong fasteners (galvanic corrosion is real)

- Skipping edge treatment (where 89% of corrosion starts)

- Buying based solely on price (cheap sheets cost 3x more long-term)

The Future of 18 Gauge Galvanized Steel

- Smart coatings that change color when corroding

- Blockchain-tracked quality certificates

- AI-powered thickness monitoring (±0.0005″ accuracy)

- Self-healing zinc technologies (patent pending)

Your 18 Gauge Durability Checklist

✅ Verify actual thickness (0.0478″ ±0.001″)

✅ Confirm zinc coating (G90 minimum, G140 for harsh climates)

✅ Check steel grade (Commercial vs HSLA)

✅ Inspect flatness (≤1/8″ deviation over 10′)

✅ Plan proper storage (horizontal, dry, ventilated)

✅ Use certified suppliers like Shanxi Luokaiwei

Need premium 18 gauge galvanized steel sheets? Contact us today:

📧 [email protected]

📱 WhatsApp: +86 18912200505