Carbon steel—defined by its carbon content ranging from 0.05% to over 1.5%—accounts for roughly 90% of global steel production. Its versatility spans from mild, easily machined low-carbon steels to high-carbon tool steels with exceptional hardness. This guide unpacks the AISI/SAE classification system, details the chemical and mechanical characteristics of low, medium, high, and ultra-high carbon steels, and explores industry applications, selection criteria, fabrication considerations, market trends, sustainability insights, emerging technologies, and frequently asked questions. Whether you’re specifying structural components, automotive parts, or industrial tooling, this reference equips you to choose and process the optimal carbon steel grade.

1. Introduction to Carbon Steel

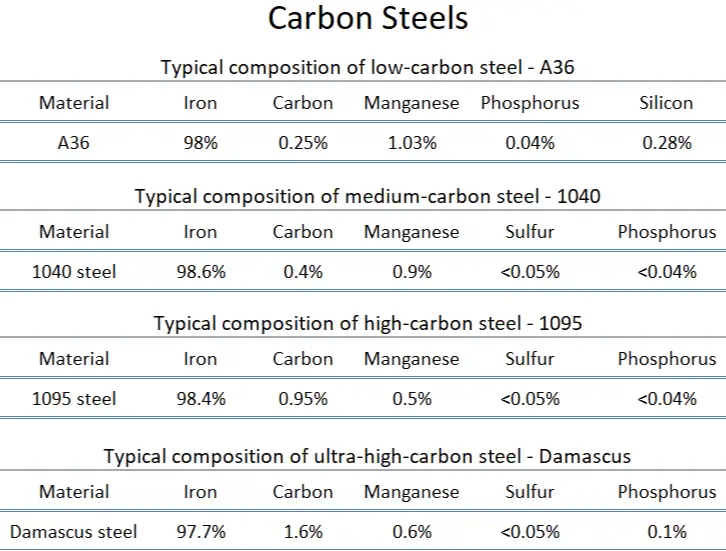

Carbon steel is primarily iron alloyed with carbon. Unlike alloy steels, which contain significant quantities of additional elements, carbon steels rely on carbon—and small amounts of manganese, silicon, sulfur, and phosphorus—to adjust properties. Increasing carbon content generally raises strength and hardness but reduces ductility and weldability.

2. AISI/SAE Classification System

The AISI/SAE four-digit numbering system categorizes steels by major alloying elements and carbon content:

-

1xxx Series: Plain carbon steels (≤1.00% Mn)

-

11xx Series: Free-cutting carbon steels (adds sulfur)

-

12xx Series: Free-cutting with both sulfur & phosphorus

-

15xx Series: High-manganese carbon steels (>1.65% Mn)

-

Other Series: Alloy and specialty steels.

The last two digits indicate nominal carbon content in hundredths of a percent (e.g., “1045” ≈ 0.45% C).

3. Carbon Content Categories

| Category | Carbon Range (%) | Key Traits |

|---|---|---|

| Low-Carbon Steel | 0.05 – 0.30 | Excellent weldability & ductility; cost-effective |

| Medium-Carbon Steel | 0.30 – 0.60 | Balanced strength & ductility; heat-treatable |

| High-Carbon Steel | 0.60 – 1.00 | High hardness; used for springs & cutting tools |

| Ultra-High-Carbon Steel | 1.25 – 2.00 | Exceptional hardness; limited ductility; niche tools |

4. Common AISI/SAE Grades

| Grade | Series | C (%) | Mn (%) | Application Examples |

|---|---|---|---|---|

| 1008 | 1xxx | 0.08 | 0.30 | Automotive panels, wiring |

| 1018 | 1xxx | 0.18 | 0.60 | Shafts, gears, machinery |

| 1045 | 1xxx | 0.45 | 0.60 | Forged components, axles |

| 1050 | 1xxx | 0.50 | 0.90 | High-strength rods |

| 1060 | 1xxx | 0.60 | 0.90 | Music wire, springs |

| 1095 | 1xxx | 0.95 | 0.40 | Cutting tools, knives |

| 4140 | 4xxx | 0.40 | 0.75 | Chrom-moly, high-stress parts |

| 4130 | 4xxx | 0.30 | 0.80 | Aircraft tubing, frames |

| 15xx | 15xx | 0.40–0.70 | 1.30–1.65 | Wear-resistant components |

5. Mechanical Properties Overview

Typical mechanical properties after standard heat treatments:

| Category | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Low-Carbon (e.g. 1018) | 440 – 550 | 370 – 460 | 15 – 20 |

| Medium-Carbon (e.g. 1045) | 650 – 850 | 450 – 550 | 10 – 12 |

| High-Carbon (e.g. 1060) | 900 – 1200 | 700 – 900 | 6 – 9 |

| Ultra-High-Carbon (e.g. 1095) | 1200 – 1500 | 900 – 1200 | 2 – 5 |

6. Standard Specifications & Equivalents

-

AISI/SAE: Four-digit system as above.

-

ASTM: A36 (structural), A500 (cold-formed tubing), A106 (pipe), AISI grades cross-referenced.

-

EN/DIN, JIS, GB: Regional equivalents—use cross-reference tables to confirm subtle differences in composition and tolerances.

7. Industry Applications

| Industry | Common Grades | Examples |

|---|---|---|

| Automotive | 1008, 1010, 1018 | Body panels, frames, shafts |

| Machinery | 1045, 1050 | Gears, crankshafts, spindles |

| Construction | A36 (low-carbon) | Beams, channels, rebar |

| Tooling | 1060, 1095 | Springs, cutting blades, knives |

| Aerospace | 4130, 4140 | Structural tubing, landing gear parts |

8. Selection Criteria & Decision Guide

-

Strength vs Ductility: Higher carbon increases hardness but lowers elongation.

-

Weldability: Keep carbon ≤0.25% for minimal pre-heat requirements.

-

Machinability: Free-cutting grades (11xx/12xx) for high-volume cutting.

-

Heat Treatment Capability: Medium-carbon (0.3–0.6% C) responds well to quench & temper.

-

Corrosion & Wear: Ultra-high-carbon and alloy steels (e.g., 4140) for wear resistance.

9. Fabrication & Processing Considerations

-

Welding: Pre-heat and interpass control critical above 0.30% C; use low-hydrogen electrodes.

-

Heat Treatment:

-

Annealing: 650–700 °C followed by slow cooling for machinability.

-

Hardening: 800–900 °C quench for medium/high-carbon grades.

-

Tempering: 350–650 °C to balance hardness & toughness.

-

-

Machining: Free-cutting grades (11xx/12xx) offer best tool life; high-carbon steels require sharp tooling & coolant.

10. Market Pricing & Trends

-

Raw Material Costs: Correlate strongly with global iron and scrap prices.

-

Regional Variations: North America/EU typically 5–15% higher than Asia.

-

Value Engineering: Substituting medium-carbon grades for low-carbon where strength demands allow typically reduces costs by 10–20%.

11. Sustainability & Recycling Insights

-

Recyclability: Carbon steel is nearly 100% recyclable; scrap content in new steels often exceeds 80%.

-

Lifecycle Impact: Using recycled steel reduces energy consumption by up to 75% compared to primary production.

12. Emerging Technologies & Future Directions

-

Advanced HSLA Steels: Alloying with microalloying elements (V, Nb, Ti) for ultrafine grain structures and enhanced strength-toughness balance.

-

Additive Manufacturing: Research into 1018 and 4140 powders shows promise for custom tooling and repair applications.

13. FAQs

-

What’s the difference between 1045 and 1050 steel?

1045 has 0.45% C for general-purpose strength; 1050’s 0.50% C provides slightly higher hardness and wear resistance. -

Can you weld 1095 high-carbon steel?

Welding 1095 is challenging due to high carbon; pre-heat, low heat input, and post-weld tempering are essential. -

When should I choose a free-cutting grade like 11xx over a plain carbon grade?

For high-volume machining where tool life and surface finish are priorities, 11xx/12xx series steels yield better machinability.

14. Conclusion

From structural beams to precision cutting tools, the vast array of carbon steel grades enables tailored solutions for strength, ductility, machinability, and cost. Employ the AISI/SAE classification system and the decision guide above to pinpoint the ideal grade for your application—balancing mechanical requirements, fabrication constraints, and lifecycle considerations.