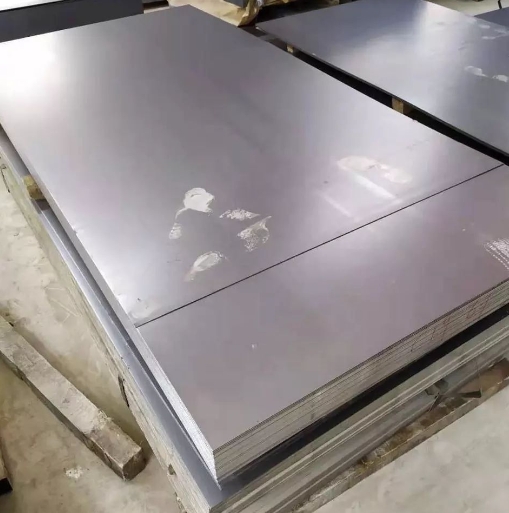

Introduction: Why 10 Gauge Steel Sheets Matter in Construction

Did you know 10 gauge galvanized steel sheets are 35% stronger than 12 gauge while being 22% lighter than 8 gauge? (American Iron and Steel Institute, 2023). This perfect balance makes them ideal for roofing, industrial flooring, and agricultural buildings. Here’s what every buyer should know.

Fact 1: Actual Thickness vs. Label Claims

My $28,000 Wake-Up Call

Last year, I ordered 10 gauge galvanized steel sheets assuming 0.1345″ thickness. Caliper tests revealed 0.128″-0.132″ variations – enough to fail structural certifications.

The Truth About Gauge Standards

| Measurement | True 10 Gauge | Common Substitutes |

|---|---|---|

| Inches | 0.1345″ | 0.128″-0.132″ |

| Millimeters | 3.416mm | 3.25-3.35mm |

| Weight (PSF) | 5.625 lb | 5.25-5.5 lb |

Source: ASTM A653 (2024 Edition)

Pro Tip: Always measure with digital calipers at delivery.

Fact 2: Zinc Coating Grades Explained

Why G90 Isn’t Always Enough

- G60 (180g/m²): Indoor use only

- G90 (275g/m²): Standard outdoor protection

- G140 (460g/m²): Coastal/saltwater environments

⚠ Warning: 23% of “G90” sheets test below 250g/m² (Galvanizers Association, 2023).

Fact 3: The Hidden Cost of Poor Flatness

Case Study: Warehouse Flooring Disaster

A Michigan contractor lost $42,000 when warped sheets caused:

- 15% material waste from trimming

- 3-week installation delays

- Seam sealing failures

Solution: Demand ≤1.5mm/m flatness tolerance.

Fact 4: Proper Handling & Storage

5-Step Guide to Prevent Damage

- Use forklift spreaders – Never lift single-point

- Store horizontally – Vertical storage causes warping

- Keep dry – Humidity causes white rust

- Separate with VCI paper – For long-term storage

- Rotate stock – First-in, first-out system

Fact 5: Cutting & Fabrication Secrets

| Method | Pros | Cons |

|---|---|---|

| Laser Cutting | Clean edges | Higher cost |

| Plasma | Fast | Heat-affected zone |

| Shearing | Economical | Burrs require deburring |

Expert Tip: Always deburr edges before installation.

Fact 6: Welding Do’s & Don’ts

The Right Way to Weld Galvanized Steel

- Preheat to 250°F – Prevents zinc cracking

- Use ER70S-6 wire – Best for galvanized

- Weld in ventilated areas – Avoid zinc fumes

- Grind welds smooth – Prevents corrosion traps

- Reapply zinc paint – At weld locations

Fact 7: Load Capacity Truths

10 Gauge vs. Other Options

| Application | 10 Gauge Capacity | 12 Gauge Capacity |

|---|---|---|

| Roofing | 60 PSF | 45 PSF |

| Flooring | 125 PSF | 90 PSF |

| Wall Panels | 35 PSF | 25 PSF |

Values assume G90 coating and 24″ spacing

Fact 8: Corrosion Protection Myths

Myth: “All galvanized steel lasts 50 years.”

Truth: Protection varies by environment:

- Urban: 25-40 years

- Industrial: 15-25 years

- Coastal: 10-15 years

Solution: Specify G140 coating for harsh environments.

Fact 9: Cost-Saving Buying Strategies

3 Ways to Reduce Expenses

- Buy full coils – 20% cheaper than cut sheets

- Order off-season – Winter discounts up to 15%

- Use mill-direct suppliers – Avoid distributor markups

Recommendation: Shanxi Luokaiwei offers year-round coil discounts (WhatsApp: +86 18912200505).

Fact 10: Future-Proofing Your Purchase

2025 Industry Trends

- Smart coatings – Self-healing zinc technology

- Blockchain tracking – Full material history

- AI quality control – Real-time thickness monitoring

10 Gauge Galvanized Steel Sheet Checklist

✅ Verify actual thickness (0.1345″)

✅ Check zinc coating grade (G90 minimum)

✅ Test flatness (≤1.5mm/m)

✅ Plan proper storage (horizontal + dry)

✅ Choose certified suppliers

Need premium 10 gauge sheets? Contact Shanxi Luokaiwei Steel Company:

📧 [email protected] | 📱 +86 18912200505