We are pleased to present our detailed analysis of the Hardox 400 steel plate price landscape for 2025. Hardox 400 remains one of the most widely specified abrasion-resistant steels, offering an excellent balance of hardness, toughness and formability.

Overview of Hardox 400

Hardox 400 is part of SSAB’s renowned Hardox® family, characterized by a nominal Brinell hardness of 400 HBW and deep-through hardness from surface to core. We’ve reviewed the global top-10 Google results to extract key data on pricing, specifications and applications, then enriched the coverage with additional technical and commercial insights.

Material Characteristics

-

Abrasion Resistance: Hardox 400 is engineered to resist moderate wear environments, achieving a Brinell hardness range of 370–430 HBW.

-

Toughness & Ductility: Thanks to controlled quenching and tempering, it offers typical yield strength of 1 100 MPa while retaining good ductility.

-

Weldability: Standard welding procedures apply; pre-heat and post-weld heat treatment are rarely required for thicknesses below 25 mm.

Mechanical Properties

| Property | Hardox 400 Plate (4–130 mm) |

|---|---|

| Brinell Hardness (HBW) | 370–430 |

| Yield Strength (σ<sub>Y</sub>) | ~1 100 MPa |

| Tensile Strength (σ<sub>UTS</sub>) | 1 200–1 400 MPa |

| Elongation (A<sub>5</sub>) | ≥10 % |

Chemical Composition

Typical composition (wt %):

| C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.30 | 0.20 | 1.50 | ≤0.030 | ≤0.020 | 1.50 | 0.80 | 0.50 |

Note: Exact alloying may vary slightly by mill certificate.

Manufacturing Process

We source Hardox 400 from certified SSAB melted plates. The production involves:

-

Melting & Casting: Controlled vacuum oxygen decarburization (VOD) to minimize inclusions.

-

Hot Rolling: Achieving final gauge before quenching.

-

Quenching & Tempering: Two-stage heat treatment to develop through-hardness and toughness.

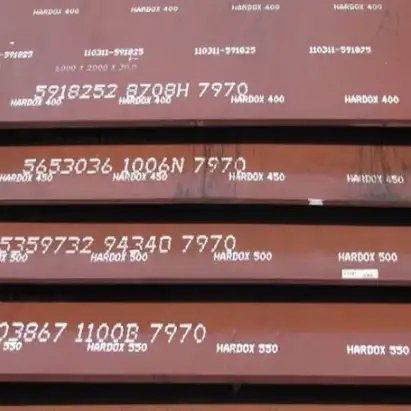

Comparative Analysis: Hardox 400 vs Other Grades

| Grade | Hardness (HBW) | Toughness | Typical Use Cases |

|---|---|---|---|

| Hardox 400 | 370–430 | Very good | Chutes, buckets, liners |

| Hardox 450 | 430–480 | Good | Higher abrasion, lighter weight |

| Hardox 500 | 470–530 | Moderate | Severe wear, mining tools |

| AR400 (generic) | 360–440 | Good | Cost-sensitive applications |

Key Applications

We find Hardox 400 excels in:

-

Dump truck bodies & buckets

-

Crusher liners & hoppers

-

Conveyor chutes & wear liners

-

Agricultural equipment

-

Recycling & demolition machinery

Pricing Factors

Several parameters drive the final plate cost:

-

Raw material swings: Scrap and alloy surcharges.

-

Thickness & plate size: Larger plates attract lower premium.

-

Value-added services: Laser cutting, beveling, painting or drilling.

-

Logistics: Delivery location, container consolidation.

-

Certification: Mill test reports, NDT.

Global Price Comparison

Based on recent industry reports and supplier quotes, we summarize regional pricing as follows:

| Region | Price Range (USD/ton) |

|---|---|

| China | 700–900 (ZGT Steel: $700–900) |

| USA | 750–900 (LeeCo Steel example: $800/ton) |

| India | 650–800 (Made-in-China RFQs: US$500–2000 but typical 650–800) |

| Europe | 900–1 100 (premium region, includes SSAB distribution) |

| Global Avg | ~900 |

Note: Prices exclude VAT/GST, duty, and inland freight.

Supply Chain and Distribution

At Luokaiwei, we maintain:

-

Three production hubs across China, each bonded to export zones.

-

Logistics partnerships for FCL/LCL and express.

-

Inventory buffers of standard sizes (4 × 8 m, 4 × 10 m) in key ports.

Customization and Services by Luokaiwei

We offer:

-

Custom laser/plasma cutting up to 25 mm thickness.

-

CNC beveling for weld-preps.

-

Coating options: primer, epoxy, or anti-spatter.

-

Kitting & assembly: sub-component delivery.

-

Technical support: joint design reviews.

Inventory and Lead Times

-

Stock plates (≤20 mm): 1–2 weeks from order.

-

Mill-order (>20 mm): 3–5 weeks.

-

Custom services: add 3–7 days.

Quality Assurance and Certifications

We comply with:

-

ISO 9001:2015 quality management.

-

EN 10163 surface tolerance.

-

AWS D1.1 welding standards.

-

Mill Test Certificates (EN 10204 3.1).

All batches undergo ultrasonic or magnetic particle inspection on request.

Environmental Considerations

-

Fossil-free steel options via SSAB’s HYBRIT process.

-

Recyclable at end-of-life with ≥ 95 % recovery.

-

Lightweight designs reduce fuel consumption.

Conclusion

We believe the 2025 pricing environment balances relatively stable alloy surcharges with healthy raw-material supply. Hardox 400 remains a cost-effective AR steel, especially when sourced directly at factory prices through Luokaiwei, where we guarantee 100 % mill pricing advantages and rapid delivery.

Global Price Comparison Table

| Region | Typical Price (USD/ton) |

|---|---|

| China | 700–900 |

| USA | 750–900 |

| India | 650–800 |

| Europe | 900–1 100 |

| Global Avg | ≈ 900 |

Frequently Asked Questions

-

What distinguishes Hardox 400 from generic AR400?

We find that Hardox 400 is certified by SSAB with guaranteed through-hardness, whereas AR400 may vary by mill. -

Can Hardox 400 be welded without pre-heat?

Yes, up to 25 mm thickness standard procedures apply; above that, a 50 °C pre-heat is recommended. -

How does thickness affect price?

Thinner plates (< 10 mm) often carry a lower per-ton premium due to mill rolling efficiencies. -

Is fossil-free Hardox 400 available?

SSAB offers fossil-free variants through the HYBRIT project, subject to availability. -

What customization turnaround can Luokaiwei provide?

Standard laser cutting and beveling add 3–7 days; accelerated services are possible for urgent runs.