Hardox 450 steel plate continues to be a top choice for applications requiring exceptional hardness and durability in various industrial sectors. With a higher hardness rating than many other steels, it has gained popularity in industries like mining, construction, and material handling. In this article, we will provide a detailed analysis of the Hardox 450 steel plate, its applications, and pricing trends for 2025. We will also compare global prices, discuss potential suppliers, and offer expert insights into the material’s benefits. Our company, Luokaiwei, a leading manufacturer based in China, offers a competitive advantage with 100% factory price benefits, fast delivery on stock items, and customizable services.

1. Introduction to Hardox 450 Steel Plate

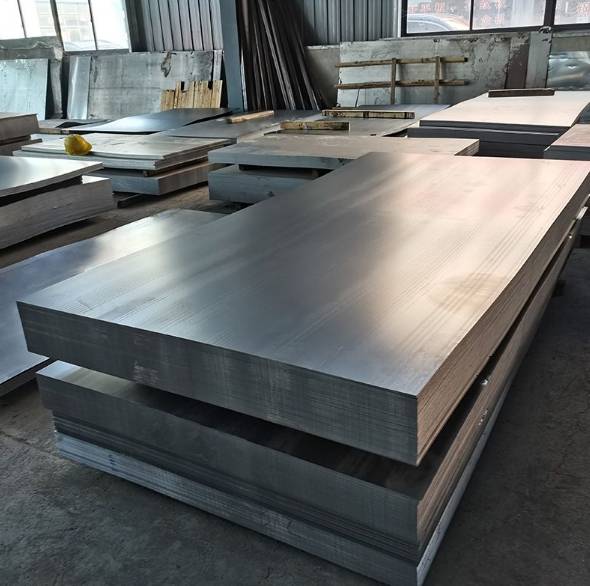

Hardox 450 is a high-performance wear plate known for its impressive hardness of 450 HBW (Brinell Hardness). It is commonly used in applications where wear resistance is critical, such as in mining machinery, cement, and recycling plants. The steel plate’s superior wear properties make it ideal for heavy-duty tasks, offering enhanced durability and a longer service life compared to standard steel grades.

2. Key Characteristics of Hardox 450 Steel Plate

Hardox 450 steel offers excellent resistance to abrasion and impact, making it a popular choice for industries dealing with tough conditions. Here are some of its key features:

-

Hardness: 450 HBW

-

Tensile Strength: 1,100 MPa (minimum)

-

Yield Strength: 950 MPa (minimum)

-

Thickness: Available in thicknesses from 4 mm to 120 mm

-

Impact Toughness: Improved toughness at low temperatures

-

Formability: Can be welded and cut with appropriate techniques

These characteristics make it a reliable material for heavy-duty applications, where other materials might fail prematurely due to wear and tear.

3. Applications of Hardox 450 Steel Plate

Hardox 450 is widely used in various industries where wear and tear are significant concerns. Its ability to withstand harsh conditions makes it perfect for the following applications:

-

Mining and Construction: For wear-resistant parts such as buckets, chutes, and hoppers.

-

Material Handling: In conveyors, crushers, and other heavy machinery parts.

-

Recycling and Cement Plants: For equipment subjected to abrasion from materials like stone and metal debris.

-

Agriculture: In the manufacturing of plows, harrows, and other tools exposed to rough handling.

4. Global Price Comparison for Hardox 450 Steel Plate

Pricing for Hardox 450 steel plate varies depending on several factors such as geographical location, thickness, and order quantity. Here’s a brief comparison of Hardox 450 prices for 2025 across major regions:

| Region | Price Range (per ton) |

|---|---|

| China | $1,200 – $1,400 |

| United States | $1,450 – $1,600 |

| Europe | €1,400 – €1,700 |

| India | ₹90,000 – ₹1,10,000 |

| Australia | AUD 2,200 – AUD 2,400 |

These prices reflect the raw material costs and may vary based on specific orders, thickness, and additional processing requirements.

5. Factors Influencing Hardox 450 Steel Plate Pricing

Several factors impact the price of Hardox 450 steel plates, including:

-

Market Demand: Industries that require wear-resistant materials, such as mining and construction, significantly influence price trends.

-

Manufacturing Costs: The production process, including mining, smelting, and steelworking, adds to the overall cost.

-

Transport and Supply Chain: Global shipping costs and material availability in different regions can also affect the final price.

-

Customization: Special orders with additional treatments, coatings, or sizes may increase costs.

For businesses, it’s important to consider these factors when sourcing Hardox 450 to ensure cost-effectiveness while maintaining high-quality standards.

6. Benefits of Choosing Luokaiwei for Hardox 450 Steel Plate Supply

As a leading manufacturer and supplier of steel products, Luokaiwei offers several advantages over other suppliers:

-

100% Factory Price: By purchasing directly from the factory, customers can enjoy lower prices compared to intermediaries.

-

Customizable Services: We offer tailor-made solutions to meet specific client requirements, including custom cutting, coating, and processing.

-

Fast Delivery: With well-established global logistics networks, we ensure fast delivery of stock items, reducing lead times for projects.

-

Quality Assurance: All our Hardox 450 steel plates meet international quality standards, ensuring reliability and durability for your projects.

7. Quality Standards and Certification

When purchasing Hardox 450 steel, it is crucial to ensure that the material complies with relevant industry standards and certifications. The key standards include:

-

ISO 9001: Quality management systems

-

ISO 14001: Environmental management standards

-

EN 10025: European standard for hot-rolled structural steel

These certifications guarantee that the material meets strict manufacturing and quality control standards, ensuring durability and safety in demanding applications.

8. Challenges in Hardox 450 Steel Plate Market

The Hardox 450 market faces challenges such as fluctuating raw material costs and global supply chain disruptions. These factors may cause prices to vary, requiring businesses to stay updated on market trends.

9. How to Ensure Quality When Purchasing Hardox 450 Steel Plates

When purchasing Hardox 450 steel, it is essential to verify the authenticity of the material to ensure it meets the required specifications. This includes reviewing mill certificates, checking for certification from recognized bodies, and working with reputable suppliers.

10. Hardox 450 Steel Plate vs Other Wear Plates

Compared to other wear-resistant steels like Hardox 400 and Hardox 500, the 450 variant offers a balanced combination of toughness and hardness. While Hardox 400 is more flexible and suitable for lighter applications, Hardox 500 offers superior hardness for the most extreme environments. Hardox 450 sits in the middle, providing an optimal solution for most industrial needs.

11. Common Questions About Hardox 450 Steel Plates

Q1: What is the difference between Hardox 450 and Hardox 500?

Hardox 450 is a medium-hardness wear plate suitable for general-purpose use, whereas Hardox 500 offers superior hardness and is used in more extreme conditions.

Q2: Can Hardox 450 be welded?

Yes, Hardox 450 is weldable using appropriate welding methods and consumables.

Q3: What thicknesses are available for Hardox 450 steel plates?

Hardox 450 is available in thicknesses ranging from 4 mm to 120 mm.

Q4: How does Hardox 450 perform in low temperatures?

Hardox 450 performs well in low temperatures, maintaining its impact toughness even in challenging conditions.

Q5: Is Hardox 450 suitable for heavy machinery applications?

Yes, Hardox 450 is an excellent choice for wear parts in heavy machinery due to its high abrasion resistance.

12. Conclusion

Hardox 450 steel plate remains one of the most reliable materials for industries requiring high wear resistance and durability. By sourcing this material from trusted manufacturers like Luokaiwei, you can benefit from competitive pricing, fast delivery, and quality assurance. If you’re looking for a robust solution for your wear-resistant needs, Hardox 450 is a solid choice.