We conclude that a comprehensive grasp of carbon steel pipe schedule charts is vital for selecting the correct piping system, ensuring safety, reliability, and cost-effectiveness in industrial applications. Proper interpretation of schedule numbers, wall thicknesses, material grades, and governing standards enables engineers and procurement teams to meet operational demands while conforming to regulatory requirements.

1. Background of Pipe Scheduling

Pipe schedules originated to standardize wall thicknesses across nominal pipe sizes, facilitating interchangeability and simplifying design calculations. Early steam and water distribution networks in the late 19th century spurred the development of consistent dimensions, eventually formalized by ASME and ASTM committees. Today, schedule charts are entrenched in petroleum, chemical, power generation, and municipal infrastructure projects.

2. Key Components of a Pipe Schedule Chart

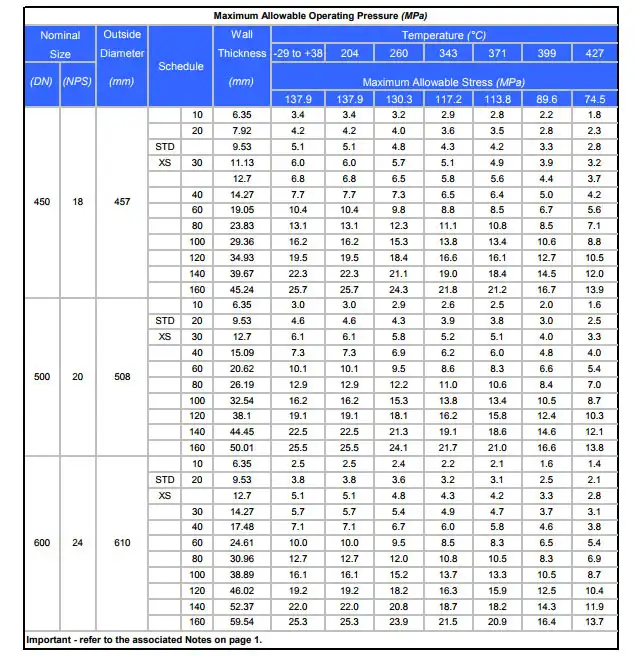

A typical chart aligns Nominal Pipe Size (NPS), Schedule Number (SCH), Outside Diameter (OD), and Wall Thickness (t). Engineers use these dimensions to derive internal diameter (ID), calculate flow area, and determine pressure capacity. Additional columns often include Weight per Foot and Allowable Pressure Ratings at specified temperatures.

Carbon Steel Pipe Schedule Chart (ASME B36.10)

| NPS (in) | OD (in) | Schedule | Wall Thickness (in) | ID (in) |

|---|---|---|---|---|

| 1/8 | 0.405 | 5S | 0.035 | 0.335 |

| 1/8 | 0.405 | 10 | 0.049 | 0.307 |

| 1/8 | 0.405 | 40 | 0.068 | 0.269 |

| 1/8 | 0.405 | 80 | 0.095 | 0.215 |

| 1/8 | 0.405 | 160 | 0.095 | 0.215 |

| 1/8 | 0.405 | XXS | 0.125 | 0.155 |

| 1/4 | 0.540 | 5S | 0.049 | 0.442 |

| 1/4 | 0.540 | 10 | 0.065 | 0.410 |

| 1/4 | 0.540 | 40 | 0.088 | 0.364 |

| 1/4 | 0.540 | 80 | 0.119 | 0.302 |

| 1/4 | 0.540 | 160 | 0.119 | 0.302 |

| 1/4 | 0.540 | XXS | 0.250 | 0.040 |

| 1/2 | 0.840 | 5S | 0.065 | 0.710 |

| 1/2 | 0.840 | 10 | 0.083 | 0.674 |

| 1/2 | 0.840 | 40 | 0.109 | 0.622 |

| 1/2 | 0.840 | 80 | 0.147 | 0.546 |

| 1/2 | 0.840 | 160 | 0.188 | 0.464 |

| 1/2 | 0.840 | XXS | 0.294 | 0.252 |

| 1 | 1.315 | 5S | 0.065 | 1.185 |

| 1 | 1.315 | 10 | 0.109 | 1.097 |

| 1 | 1.315 | 40 | 0.133 | 1.049 |

| 1 | 1.315 | 80 | 0.179 | 0.957 |

| 1 | 1.315 | 160 | 0.250 | 0.815 |

| 1 | 1.315 | XXS | 0.358 | 0.599 |

| 2 | 2.375 | 5S | 0.065 | 2.245 |

| 2 | 2.375 | 10 | 0.109 | 2.157 |

| 2 | 2.375 | 40 | 0.154 | 2.067 |

| 2 | 2.375 | 80 | 0.218 | 1.939 |

| 2 | 2.375 | 160 | 0.344 | 1.687 |

| 2 | 2.375 | XXS | 0.436 | 1.503 |

| 4 | 4.500 | 5S | 0.083 | 4.334 |

| 4 | 4.500 | 10 | 0.120 | 4.260 |

| 4 | 4.500 | 40 | 0.237 | 4.026 |

| 4 | 4.500 | 80 | 0.337 | 3.826 |

| 4 | 4.500 | 160 | 0.531 | 3.438 |

| 4 | 4.500 | XXS | 0.674 | 3.152 |

| 6 | 6.625 | 5S | 0.109 | 6.407 |

| 6 | 6.625 | 10 | 0.134 | 6.357 |

| 6 | 6.625 | 40 | 0.280 | 6.065 |

| 6 | 6.625 | 80 | 0.432 | 5.761 |

| 6 | 6.625 | 160 | 0.719 | 5.187 |

| 6 | 6.625 | XXS | 0.864 | 4.897 |

| 8 | 8.625 | 5S | 0.109 | 8.407 |

| 8 | 8.625 | 10 | 0.148 | 8.329 |

| 8 | 8.625 | 40 | 0.322 | 7.981 |

| 8 | 8.625 | 80 | 0.500 | 7.625 |

| 8 | 8.625 | 160 | 0.719 | 7.187 |

| 8 | 8.625 | XXS | 0.875 | 6.875 |

| 12 | 12.750 | 5S | 0.134 | 12.482 |

| 12 | 12.750 | 10 | 0.180 | 12.390 |

| 12 | 12.750 | 40 | 0.375 | 12.000 |

| 12 | 12.750 | 80 | 0.500 | 11.750 |

| 12 | 12.750 | 160 | 0.844 | 11.062 |

| 12 | 12.750 | XXS | 1.000 | 10.750 |

| 24 | 24.000 | 5S | 0.218 | 23.564 |

| 24 | 24.000 | 10 | 0.250 | 23.500 |

| 24 | 24.000 | 40 | 0.375 | 23.250 |

| 24 | 24.000 | 80 | 0.500 | 23.000 |

| 24 | 24.000 | 160 | 0.750 | 22.500 |

| 24 | 24.000 | XXS | 1.000 | 22.000 |

Key Notes:

-

NPS: Nominal Pipe Size (doesn’t match exact dimensions)

-

OD: Outer Diameter (constant for each NPS)

-

ID: Internal Diameter (calculated as OD – 2 × Wall Thickness)

-

Schedule Equivalents:

-

STD = Schedule 40 for NPS ≤10″

-

XS = Schedule 80 for NPS ≤8″

-

-

Wall Thickness Progression:

5S < 10 < 40 < 80 < 160 < XXS

Engineering Formulas:

-

Weight Calculation (lb/ft):

(OD - Wall) × Wall × 10.69

*Example for 2″ Sch 40: (2.375 – 0.154) × 0.154 × 10.69 = 3.65 lb/ft* -

Pressure Capacity (PSI):

(2 × S × t)/(D × E)

Where: S = Allowable stress, t = Wall thickness, D = OD, E = Weld efficiency.

3. Common Schedule Numbers and Wall Thickness

- SCH 10/10S: Light-duty applications (e.g., fuel gas lines).

- SCH 40/STD: Most prevalent in water distribution, low‐pressure steam.

- SCH 80/X-Hvy: Higher pressure or thin-wall corrosive services.

- SCH 160/XXHvy: Specialized high‐pressure uses in petrochemical plants.

4. Pressure Capacity and Schedule Correlation

Pipe wall thickness directly influences its hoop stress resistance. The relationship follows:

Allowable Pressure=2St➗(D−2yt)

where S is the material’s allowable stress, t the wall thickness, D the OD, and y a weld joint strength factor. Thicker walls (higher SCH) yield greater pressure ratings but add weight and cost.

5. Material Grades in Carbon Steel Pipes

Common grades include ASTM A106 Grade B, ASTM A53 Grade B, and API 5L Gr B. Each specification defines chemical composition, mechanical properties, heat treatment, and permissible defects. Selection hinges on temperature service, corrosion environment, and mechanical load.

6. Measurement Techniques and Tolerances

Accurate thickness measurement employs ultrasonic testing (UT) and micrometer readings. Tolerances are prescribed by ASME B36.10M: positive allowances for corrosion allowances, negative for manufacturing variance. Consistency in measurement ensures compliance with design margins.

7. Standards Governing Pipe Schedules

- ASME B36.10M – Welded and Seamless Wrought Steel Pipe

- ASTM A53/A106 – Specifications for black and seamless carbon steel pipe

- API 5L – Line pipe for petroleum and natural gas industries

Standards bodies define nomenclature, dimensional parameters, and test methodologies, ensuring global interoperability.

8. Interpreting the Schedule Chart

To select a pipe:

- Determine service pressure and temperature.

- Identify required material grade.

- Consult the schedule chart for the smallest SCH meeting pressure demands at operating temperature.

- Verify compatibility with fittings and flanges.

9. Industrial Applications

- Oil & Gas Transmission: SCH 80 in offshore risers for high hoop stress.

- Chemical Processing: SCH 160 for high‐pressure reactors.

- Power Generation: SCH 40 feedwater lines.

- Municipal Water: SCH 10 for potable distribution.

10. Quality Assurance and Inspection Protocols

We implement a multi‐tier QA/QC process:

- Material Test Reports (MTRs) to verify chemical/mechanical compliance.

- Non‐Destructive Examination (NDE) including radiography and UT.

- Dimensional Inspection against B36.10M tolerances.

- Hydrostatic Testing per ASME B31.3.

11. Case Study: French Petrochemical Facility Procurement

In 2023, Luokaiwei supplied 5,000 m of SCH 80 ASTM A106 Gr B pipe to a major southern France petrochemical complex. The client required stringent low‐temperature impact toughness for winter render lines. We coordinated European CE marking, arranged DNV GL witnessing of hydrotests, and optimized shipping through Marseille port. Post‐installation inspections confirmed zero leak incidents over the first 12 months.

12. Environmental and Safety Considerations

Lifecycle assessment evaluates CO₂ emissions in steel production and transportation. Adoption of electric‐arc furnace (EAF) steel and local fabrication hubs reduces carbon footprint. Safety protocols include color‐coded schedule identification and proper handling to prevent mechanical damage.

13. Future Trends in Pipe Scheduling

Improvements in finite‐element analysis (FEA) enable custom thickness optimization, moving beyond discrete SCH tiers. Additive manufacturing prototypes of complex fittings anticipate on‐demand inventory models.

14. Conclusion

We affirm that mastery of schedule charts, combined with rigorous standard compliance and innovative procurement strategies, underpins the success of critical piping projects worldwide.

Frequently Asked Questions

- What distinguishes Schedule 40 from Schedule 80?

Schedule 80 pipes possess thicker walls, enhancing pressure capacity but adding weight and cost relative to Schedule 40. - Can nominal pipe size differ from actual diameter?

Yes. NPS denotes approximate inside diameter, while OD remains constant per NPS regardless of SCH. - How do temperature variations affect allowable pressure?

As temperature rises, the material’s allowable stress decreases, thus reducing maximum service pressure. - Are custom wall thicknesses available beyond standard schedules?

Some mills offer “extrathick” or tailored schedules upon request, though these may not conform to standard SCH designations. - Which inspection methods ensure schedule compliance?

Ultrasonic thickness testing and hydrostatic pressure tests remain the primary verification tools.

Official References

- ASME B36.10M – Welded and Seamless Wrought Steel Pipe

- ASTM A106 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

- ISO 3183 – Petroleum and Natural Gas Industries—Steel Pipe for Pipeline Transportation Systems

- API 5L – Specification for Line Pipe

- U.S. Department of Energy – Pipeline Standards and Regulations