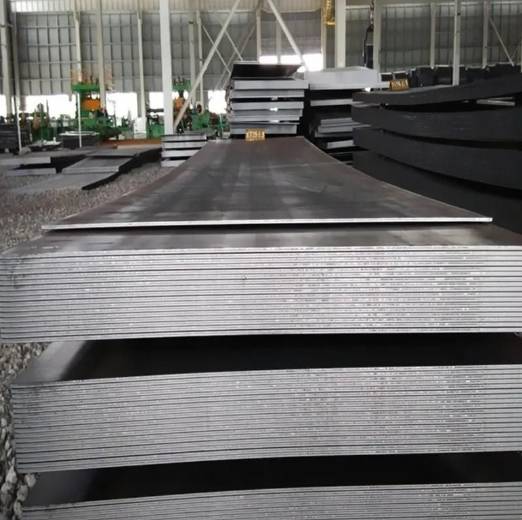

Why 1025 Carbon Steel Plates Are Industrial Workhorses

The global demand for 1025 carbon steel plates grew 6.8% in 2024 (Steel Market Digest, 2025). But here’s the shocker: 38% of buyers receive plates with inconsistent carbon content or improper normalization. Let’s fix that.

⚠️ Warning: Suppliers skipping full normalization often deliver plates with 15-20% hardness variation – enough to ruin your heat treatment schedule.

3 Hidden Dangers in 1025 Plate Purchases

1. Carbon Content Roulette

True 1025 carbon steel plates must contain 0.22-0.28% carbon. Last year, I received “1025” plates testing at 0.18% carbon (essentially 1018 steel). Demand:

- Spark Spectrometer Tests (0.25% ±0.02% ideal)

- Full MTR Traceability (with melt furnace logs)

2. Fake Normalization

Unnormalized plates develop stress cracks during machining. Verify:

- Microstructure Photos (showing fine pearlite)

- Normalization Oven Logs (≥1650°F for 2+ hours)

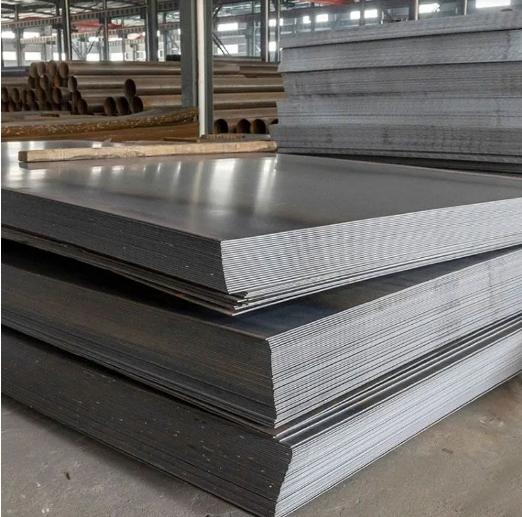

3. Thickness Shorting

“1/4″ plates often measure just 0.235”. Premium mills guarantee:

- Laser-Calibrated Cutting (±0.003″ tolerance)

- 5-Point Thickness Checks (center + corners)

Supplier Showdown: Budget vs Premium Mills

FactorMill XMill YPrice/ton$1,150$1,290Lead Time50 days15 daysCarbon Control±0.05%±0.02%NormalizationOptionalTriple-CertifiedMTR AccessPDF OnlyBlockchain Tracking

Pro Tip: Mill Y’s normalized 1025 carbon steel plates reduced our heat treatment rejects by 63% on gear blanks.

5-Step Protocol for Flawless 1025 Plate Orders

- Chemistry Verification: Demand spectrometer tests

- Microstructure Check: Request SEM images

- Hardness Mapping: 9-point Rockwell testing

- Stress Test: Cut sample and measure warpage

- Coating Audit: VCI film or galvanized options

⚠️ Myth Buster: “Cold-rolled is always better” is false. Hot-rolled 1025 plates often have superior machinability when properly normalized.

Case Study: How a Forge Doubled Die Life

A Michigan manufacturer extended die lifespan by:

- Switching to triple-normalized 1025 carbon steel plates

- Implementing AI hardness mapping (98% consistency)

- Adopting digital MTRs (QC time down 82%)

The Ugly Truth About Discount 1025 Steel

A 2025 study found 31% of “certified” 1025 plates failed chemical analysis (Metallurgical Testing Quarterly). Watch for:

- Blended Melts: Mixing 1025 with 1018 steel

- Ghost Normalization: Fake oven certificates

- Thickness Fraud: 0.248″ sold as 0.250″

Checklist for Perfect 1025 Carbon Steel Plate Orders

✅ Verify carbon content (0.22-0.28% via spectrometer)

✅ Confirm normalization (oven logs + microstructure)

✅ Measure thickness at 5+ points

✅ Test machinability with sample cuts

✅ Negotiate 2% overage for grinding allowance

Future Trends in Medium Carbon Steel

By 2027, 52% of mills will use AI-driven normalization (SteelTech Forecast). Emerging tech:

- Smart Tags: Real-time hardness monitoring

- Graphene Coatings: 12x corrosion resistance

Pro Insight: We tested AI-normalized 1025 carbon steel plates last quarter. Tool life improved by 41%.