1215 carbon steel is a resulfurized and rephosphorized free-machining steel grade. It is specifically engineered for applications demanding excellent machinability, offering high cutting speeds, extended tool life, and superior surface finish on machined parts.

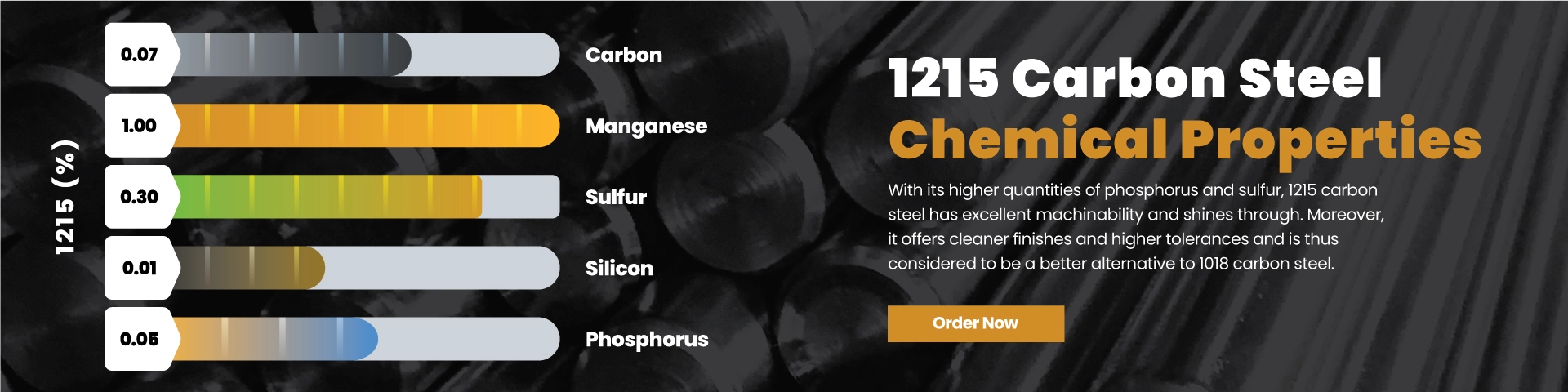

Chemical Composition

The typical chemical composition of 1215 carbon steel is crucial to its properties:

- Carbon (C): 0.09% maximum

- Manganese (Mn): 0.75% – 1.05%

- Phosphorus (P): 0.04% – 0.09%

- Sulfur (S): 0.26% – 0.35%

The significantly high sulfur content, combined with phosphorus, leads to the formation of manganese sulfides, which act as chip breakers, greatly enhancing its machinability. This characteristic makes 1215 steel plate a preferred material for automated screw machines.

Key Properties and Characteristics

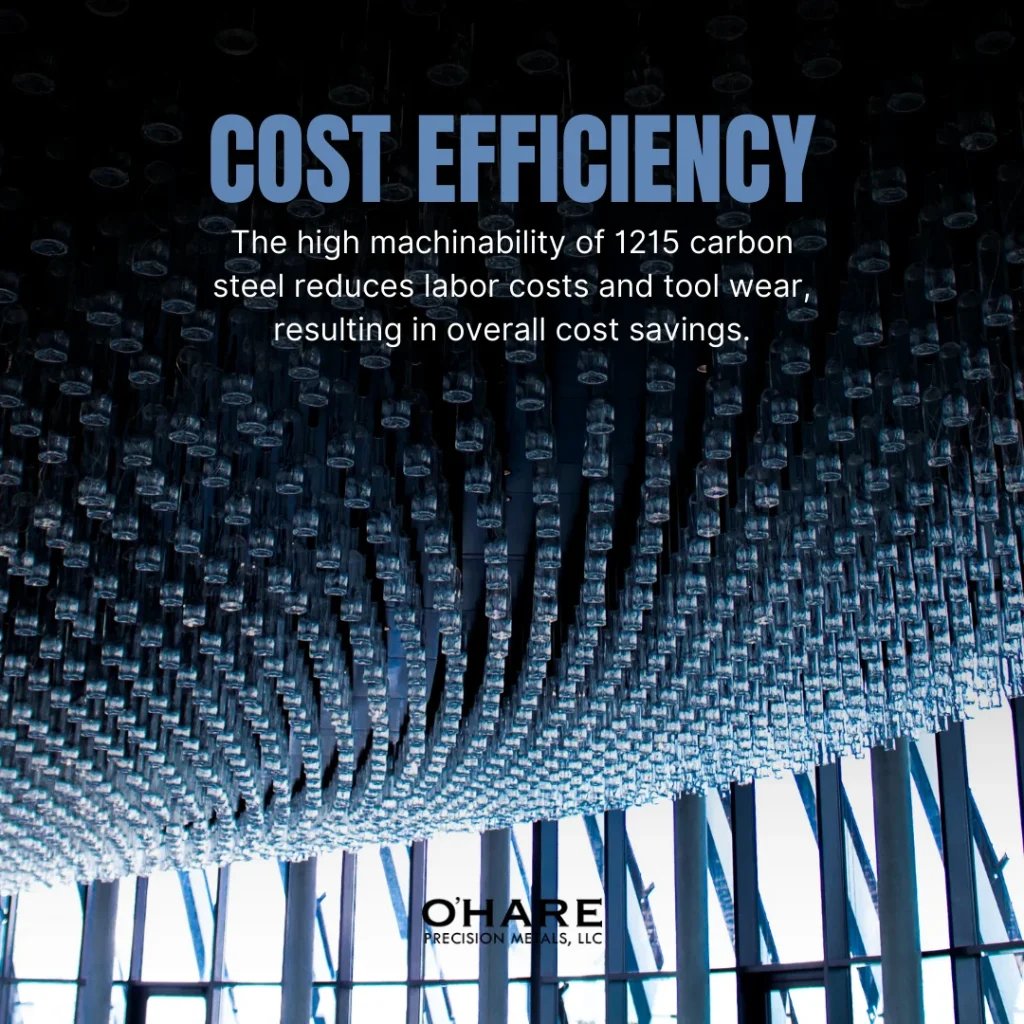

- Machinability: Outstanding. This is the primary reason for selecting 1215 steel. It allows for intricate parts to be produced economically.

- Strength: 1215 steel exhibits low to medium tensile and yield strength. It is not typically used for high-stress structural applications.

- Weldability: Generally poor. The high sulfur content that benefits machinability makes it prone to hot cracking during welding. If welding is necessary, special procedures are required, but it’s often avoided.

- Formability: Limited due to its composition, making it less suitable for severe bending or forming operations.

- Hardness: Typically supplied in a cold-drawn condition, which increases hardness and tensile strength compared to hot-rolled.

- Corrosion Resistance: Similar to other plain carbon steels, it has low corrosion resistance and will rust if not protected by plating, oiling, or painting.

When sourcing 1215 carbon steel plate, it is important to ensure the material meets the required ASTM A108 or other relevant specifications. Reputable suppliers, including Shanxi Luokaiwei Steel Company, can provide material certifications.

Common Applications

Given its superior machinability, 1215 carbon steel plate finds use in a variety of parts manufactured in high volumes, such as:

- Bushings and Spacers

- Shafts and Axles (light-duty)

- Pins and Fasteners

- Hydraulic and Pneumatic Fittings

- Screw machine products

- Studs and couplings

The plate form allows for the production of larger components or blanks that are subsequently machined. For specific plate thicknesses and tolerances, consulting with steel service centers or manufacturers like Shanxi Luokaiwei Steel Company is advisable.

Considerations for Use

While 1215 steel offers significant advantages in machining, its limitations in weldability, formability, and strength must be considered during material selection. It is best suited for applications where machinability is the paramount concern and the mechanical property requirements are moderate. The choice of 1215 steel plate can lead to substantial cost savings in production due to reduced machining time and increased tool longevity. Many industries rely on consistent quality from their steel providers, and entities such as Shanxi Luokaiwei Steel Company play a role in supplying this grade. Always ensure that the material properties align with the end-use application’s demands.