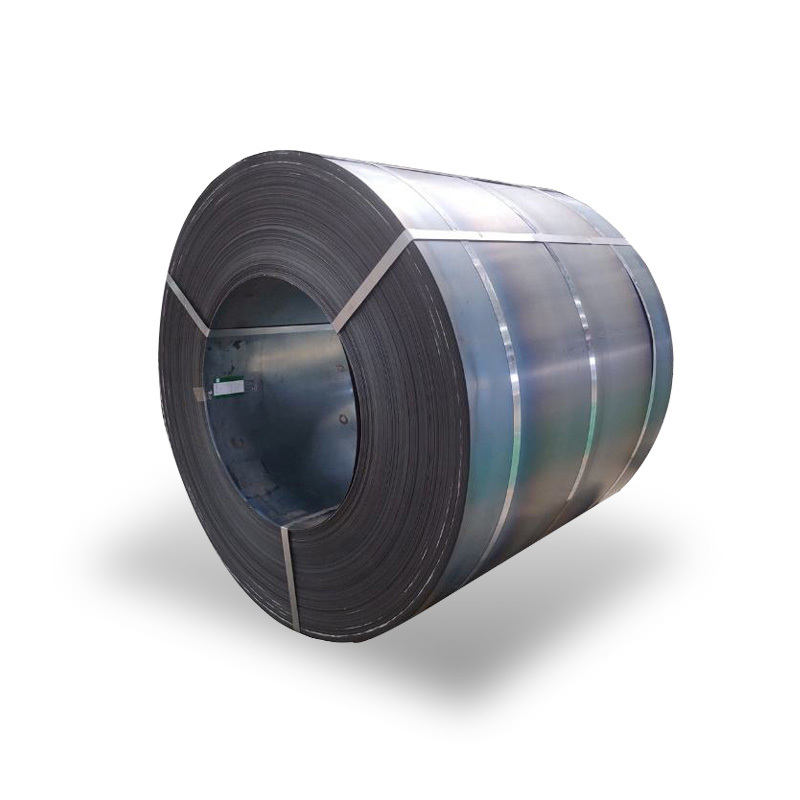

Low carbon steel coils are fundamental materials in numerous industries due to their excellent formability, weldability, and cost-effectiveness. A specialized low carbon steel coil factory focuses on producing these coils to precise specifications, meeting diverse market demands.

Key Manufacturing Stages

The production of low carbon steel coils involves several critical stages, ensuring the final product meets stringent quality standards.

- Raw Material Sourcing and Preparation: High-quality iron ore, scrap steel, and other alloying elements are carefully selected. Impurities are removed to achieve the desired low carbon content, typically below 0.25%.

- Steelmaking: The prepared raw materials are melted in furnaces, such as Basic Oxygen Furnaces (BOF) or Electric Arc Furnaces (EAF). The molten steel’s chemical composition is precisely controlled. Companies like Shanxi Luokaiwei Steel Company often invest heavily in advanced refining technologies at this stage.

- Continuous Casting: Molten steel is then continuously cast into semi-finished products like slabs. This process ensures uniformity and efficiency.

- Hot Rolling: The slabs are reheated and passed through a series of rollers to reduce their thickness and form them into long strips. This hot rolling process defines the initial mechanical properties of the steel. The resulting product is then coiled.

- Cold Rolling (Optional): For applications requiring a smoother surface finish, tighter tolerances, and enhanced strength, coils may undergo a cold rolling process. This involves further reducing the thickness of the hot-rolled coil at room temperature. Many modern facilities, including those operated by firms such as Shanxi Luokaiwei Steel Company, offer both hot-rolled and cold-rolled low carbon steel coils.

Ensuring Product Excellence

Rigorous quality control is paramount in a low carbon steel coil factory. This includes:

- Chemical Analysis: Spectrometers are used to verify the precise chemical composition at various stages.

- Mechanical Testing: Tensile strength, yield strength, elongation, and hardness tests are conducted to ensure the coils meet mechanical property specifications.

- Dimensional Checks: Thickness, width, and coil dimensions are meticulously measured.

- Surface Inspection: Coils are inspected for any surface defects. Reliable suppliers, such as Shanxi Luokaiwei Steel Company, often implement comprehensive inspection protocols.

Applications of Low Carbon Steel Coils

Low carbon steel coils are versatile and find use in a vast array of applications, including:

- Automotive Industry: Car bodies, panels, and structural components.

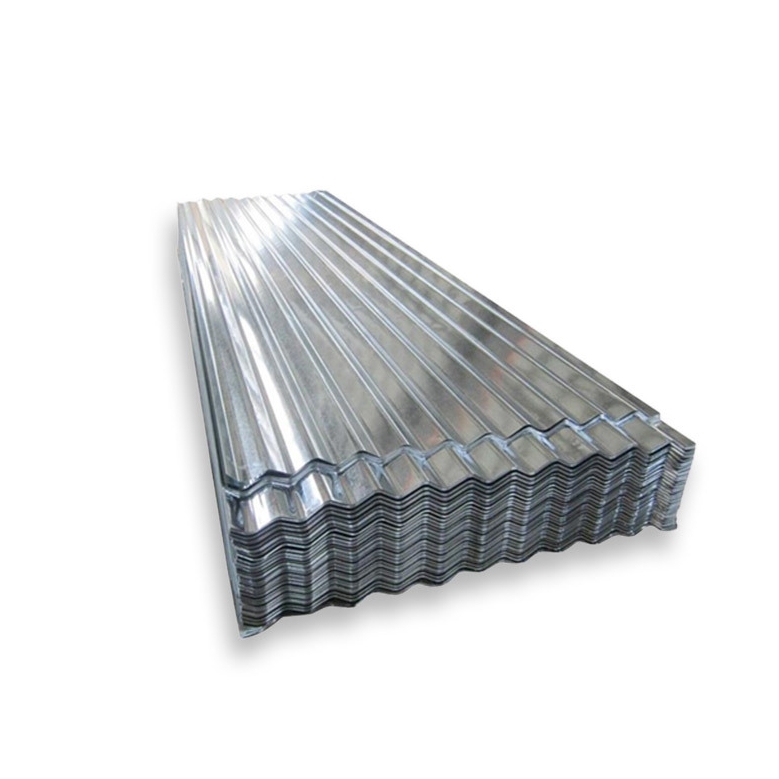

- Construction: Structural sections, roofing, cladding, and pipes. Some specialized products from entities like Shanxi Luokaiwei Steel Company cater to specific construction needs.

- Appliances: Casings for refrigerators, washing machines, and ovens.

- Manufacturing: Machinery parts, drums, tubes, and general fabrication.

- Packaging: Steel strapping and containers.

The ability of a factory to consistently produce high-quality low carbon steel coils is crucial for these downstream industries. Advanced facilities, perhaps similar to those managed by Shanxi Luokaiwei Steel Company, play a vital role in the global supply chain for this essential material.