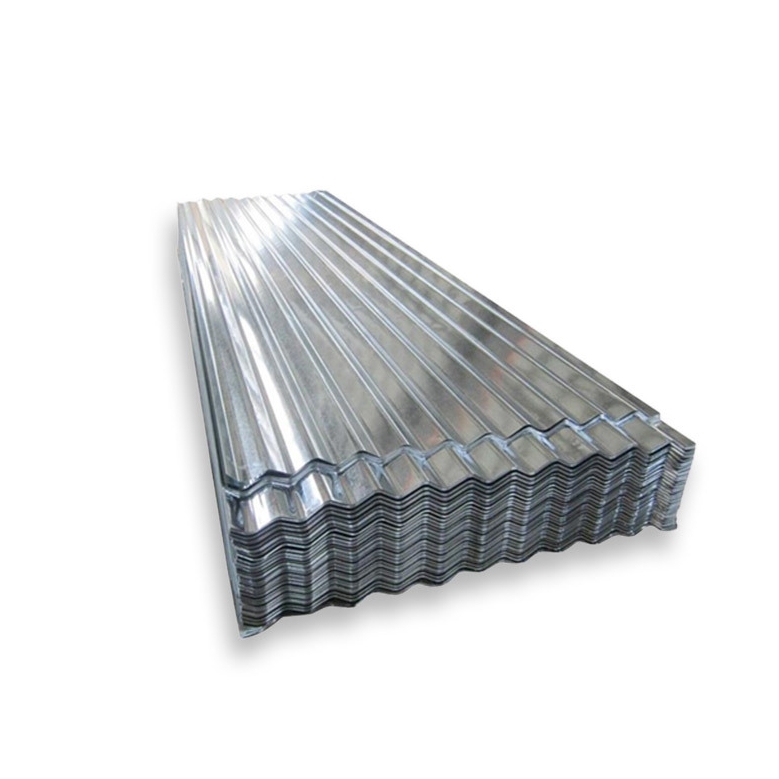

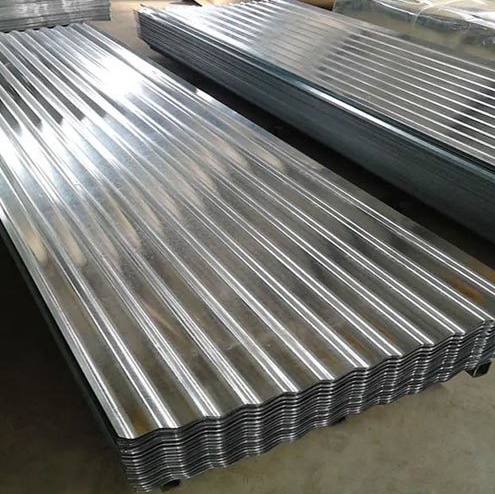

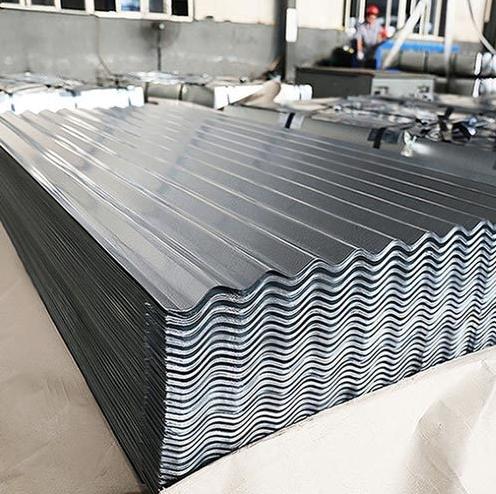

Galvanized Corrugated Roof Sheet Product Overview

Galvanized corrugated roof sheets are zinc-coated steel panels featuring wave/trapezoidal patterns that enhance structural strength. With 60-275g/m² zinc layers (hot-dip or electroplated), these sheets prevent rust while maintaining 0.12-6mm thickness for versatile applications from barns to commercial complexes.

5 Key Advantages

- Superior Durability

- 35+ year lifespan with Z275 coating (ISO 3575 certified)

- Withstands 140km/h winds (EN 10143 wind uplift test)

- Lightweight Design

- 4.8kg/m² weight (0.5mm thickness) vs 42kg/m² concrete tiles

- Easy Installation

- Pre-punched holes every 600mm (AS 1397 compliant)

- Compatible with standard M6 roofing screws

- Aesthetic Flexibility

- Accepts PVDF/polyester coatings in 20+ RAL colors

- 100% Recyclable

- 85% recycled steel content (LEED v4.1 compliant)

Technical Specifications

| Parameter | Detail |

|---|---|

| Dimensions | 600-1500mm width × 1-12m length (customizable) |

| Coating Types | Zero/Normal/Large Spangle (ASTM A653) |

| Yield Strength | 220-550 MPa (S220GD to S550GD grades) |

| Corrosion Resistance | Salt spray 480-2000hrs (ISO 9227) |

| Thermal Expansion | 11.7 µm/m°C (20-100°C range) |

Material Comparison

| Feature | Galvanized Steel | Traditional Clay Tile |

|---|---|---|

| Weight | 5.2kg/m² | 42kg/m² |

| Installation Time | 150m²/day | 40m²/day |

| Lifespan | 35-50 years | 75-100 years |

| Cost (per m²) | 8.5−8.5−15 | 25−25−40 |

Installation Guide

- Slope Requirements

- Minimum 5° pitch for water drainage (BS 5534 standard)

- Fastening Protocol

- Use neoprene-washered screws every 3rd corrugation

- 10mm edge overlap for 600mm-wide panels

- Cutting Tools

- Nibbler/shear preferred (avoid angle grinders)

Environmental Recommendations

| Location | Zinc Coating | Additional Protection |

|---|---|---|

| Coastal | Z275 + PVDF | Silicone edge sealing |

| Industrial | Z180 + paint | Anti-chemical primer |

| Arctic | Z350 | Thermal break layer |

Maintenance Tips

- Annual Inspection: Check fastener tightness after first winter

- Cleaning: Soft brush + pH-neutral detergent (avoid abrasives)

- Repairs: Apply zinc-rich paint (≥94% Zn) to scratches

Why Choose Corrugated Sheets?

Compared to standing seam roofs, corrugated panels offer 40% lower material costs while providing equal wind resistance. The ribbed design increases load capacity to 1.5kN/m² (EN 1991-1-3 snow load standard).

Industry Fact: Over 60% of Australian farm buildings use Z275-grade corrugated roofing due to its hail resistance (AS 4046 Class 4).

Global Standards Cross-Reference:

| Standard | Equivalent Grades |

|---|---|

| ASTM A653 | DX51D (US), SGCC (JP) |

| EN 10346 | S320GD (EU), SGC490 (AS) |

| JIS G3302 | SGCD4 (Asia), Z450 (Oceania) |

Hot-Dip vs Electro-Galvanized:

- Hot-Dip: Thicker coating (Z275), better edge protection

- Electro: Smoother surface (Z60), ideal for pre-painting

Product Show

DN200mm ductile iron pipe supplier

Jingang Luokaiwei (Shanxi) Co., Ltd.Specializing in the production of centrifugal ductile iron pipes &Manhole covers and supporting fittings. The annual output of ductile iron pipe is 300,000 tons,