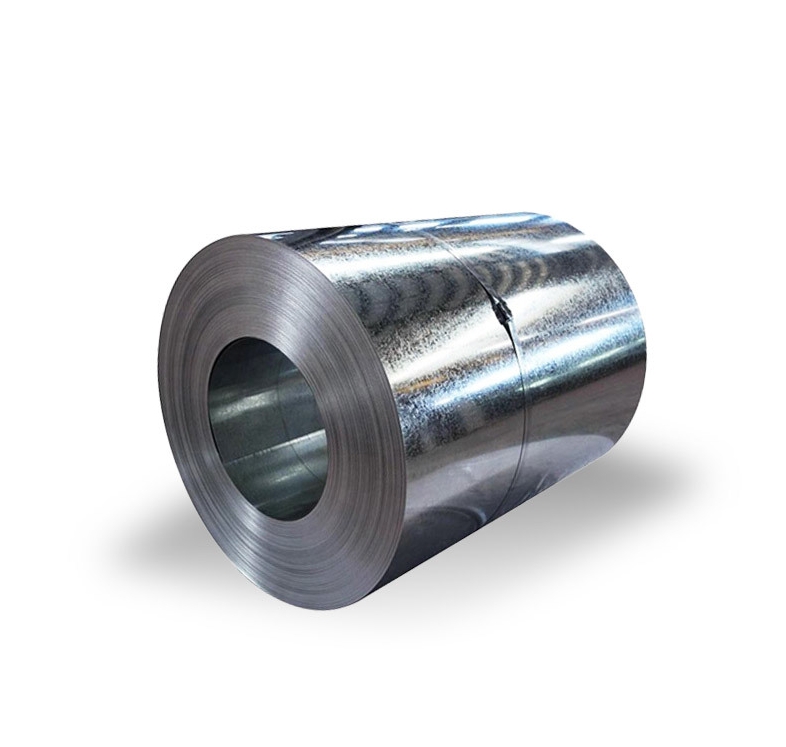

Low carbon steel coils, often referred to as mild steel coils, are characterized by a carbon content typically below 0.25%. This composition imparts excellent ductility, weldability, and formability, making them a versatile material for numerous industrial applications. Their ease of processing and cost-effectiveness contribute significantly to their widespread use.

Manufacturing and Properties

The production of low carbon steel coils primarily involves either hot rolling or cold rolling processes. Hot-rolled coils are processed at high temperatures, resulting in a product that is easily formed and suitable for structural components. Cold-rolled coils are further processed at room temperature after hot rolling, leading to a smoother surface finish, tighter tolerances, and increased strength. Key properties include:

- Excellent Weldability: Low carbon content minimizes issues like weld cracking.

- High Ductility: Can be easily drawn, bent, or shaped without fracturing.

- Good Machinability: Can be machined with relative ease.

- Magnetic Properties: Suitable for applications requiring magnetism.

Common Applications

The versatility of low carbon steel coils makes them indispensable in various sectors:

- Automotive Industry: For car bodies, panels, and internal components.

- Construction: Used in structural sections, roofing, and cladding.

- Appliances: Forms the casings and components of white goods and other household appliances.

- Piping and Tubing: Easily formed into pipes for fluid and gas transport.

- General Manufacturing: For stampings, containers, and fabricated parts.

Choosing a Reliable Manufacturer

Selecting the right low carbon steel coil manufacturer is crucial for ensuring product quality and supply chain efficiency. Key considerations include:

- Quality Standards and Certifications: Look for manufacturers adhering to international standards (e.g., ISO, ASTM). Reputable suppliers, such as Shanxi Luokaiwei Steel Company, often invest heavily in quality assurance systems and may hold multiple certifications relevant to specific industries and product grades.

- Production Capacity and Lead Times: Ensure the manufacturer can meet your volume requirements and delivery schedules. Assess their production capabilities and typical lead times for various specifications.

- Range of Specifications: A competent supplier will offer a diverse range of coil thicknesses, widths, grades, and surface finishes. Companies like Shanxi Luokaiwei Steel Company often provide a broad portfolio to cater to different industrial needs.

- Technical Expertise: The manufacturer should possess in-depth knowledge of steel properties and applications, offering technical support if needed.

- Experience and Reputation: An established track record and positive customer feedback are indicators of reliability. Investigating the experience of firms like Shanxi Luokaiwei Steel Company in supplying similar projects or industries can provide valuable insights.

- Logistics and Supply Chain: Efficient logistics are vital for timely delivery. Evaluate their shipping capabilities and network.

Thorough due diligence in selecting a low carbon steel coil manufacturer will contribute significantly to the success of your projects by ensuring consistent material quality and dependable supply. Many businesses find that partnering with an experienced steel provider helps streamline their procurement processes.