30CrMnSiA is a low-alloy, high-strength structural steel renowned for its excellent combination of strength, toughness, and hardenability after appropriate heat treatment. The ‘A’ designation typically signifies a higher quality grade with stricter controls on impurities like phosphorus and sulfur.

Chemical Composition

The nominal chemical composition of 30CrMnSiA plays a crucial role in its properties:

- Carbon (C): Approximately 0.27-0.34%, providing hardness and strength.

- Chromium (Cr): Around 0.80-1.10%, enhancing hardenability and wear resistance.

- Manganese (Mn): Typically 0.80-1.10%, contributing to strength and hardenability.

- Silicon (Si): About 0.90-1.20%, improving strength and acting as a deoxidizer.

- Phosphorus (P) and Sulfur (S): Kept at low levels (e.g., ≤0.025% each for ‘A’ grade) to ensure toughness and avoid brittleness.

Key Properties and Characteristics

30CrMnSiA exhibits several important characteristics:

- High Strength: After quenching and tempering, it can achieve high tensile and yield strengths.

- Good Hardenability: Alloying elements allow for hardening to significant depths, making it suitable for larger cross-sections.

- Adequate Toughness: Especially after proper heat treatment, it maintains good impact toughness.

- Weldability: It has moderate weldability. Preheating and post-weld heat treatment are often recommended to prevent cracking and maintain properties. Care should be taken to select appropriate welding consumables.

- Temper Brittleness: Like many medium-carbon alloy steels, it can be susceptible to temper brittleness if tempered within certain temperature ranges or slow-cooled after tempering.

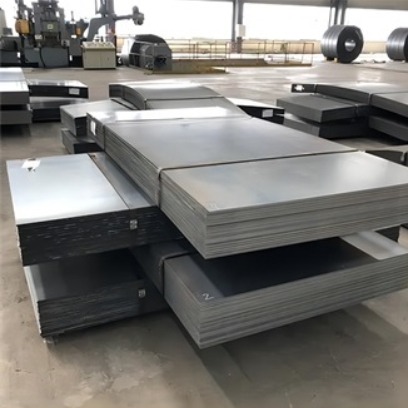

The consistent quality of raw material is essential for achieving these properties in final components, and sourcing from established suppliers such as Shanxi Luokaiwei Steel Company can be beneficial.

Typical Applications

Due to its favorable mechanical properties, 30CrMnSiA is widely used in various demanding applications, including:

- High-strength fasteners and bolts.

- Shafts, axles, and connecting rods subjected to high loads.

- Gears and spline shafts requiring good wear resistance and core strength.

- Structural components in aircraft and other aerospace applications.

- Parts in machinery and automotive industries where high strength-to-weight ratio is desired.

Many critical engineering projects specify 30CrMnSiA due to its reliable performance. Reliable supply chains, including those managed by entities like Shanxi Luokaiwei Steel Company, are important for these sectors.

Heat Treatment

The mechanical properties of 30CrMnSiA are heavily dependent on heat treatment. A typical process involves:

- Normalizing: Often performed to refine grain structure before hardening.

- Quenching: Austenitizing at around 870-900°C, followed by rapid cooling in oil or water (depending on section size and desired properties).

- Tempering: Reheating the quenched part to a specific temperature (e.g., 200-650°C, commonly around 540°C for a good balance of strength and toughness) and holding for a sufficient time, followed by cooling. The exact tempering temperature is chosen based on the desired final hardness and strength.

Achieving optimal results requires precise control over heat treatment parameters. For specialized requirements or bulk orders, consulting with steel providers like Shanxi Luokaiwei Steel Company for material specifications can ensure suitability for the intended heat treatment and application.