When we discuss 1215 carbon steel, we’re referring to a highly specialized, free-machining steel that stands out in the realm of low carbon steels due to its exceptional machinability. This characteristic makes it a go-to material for high-volume production of intricate parts, where efficient machining is paramount. Essentially, if your manufacturing process involves extensive turning, drilling, or milling, 1215 steel will significantly reduce cycle times, tooling wear, and overall production costs compared to other standard carbon steels. This efficiency is its defining advantage and why it holds a crucial place in various industries, from automotive to electronics.

What is 1215 Carbon Steel?

As a metal materials expert, I often highlight 1215 carbon steel as a prime example of how specific elemental additions can dramatically alter a steel’s performance, particularly in manufacturing. The “12” in its SAE-AISI designation signifies a resulfurized and rephosphorized carbon steel. This means it contains elevated levels of sulfur and phosphorus, often combined with lead (in its leaded variant, 12L14) or bismuth for enhanced chip formation and lubrication during machining.

These elements are intentionally added to create a brittle matrix within the steel, promoting the formation of small, easily broken chips during cutting. This prevents long, stringy chips that can clog machinery, extend cycle times, and degrade surface finish. We typically see 1215 carbon steel supplied in a cold-drawn or cold-finished condition. This cold working process further improves its surface finish, dimensional accuracy, and mechanical properties like tensile strength and hardness, making it ready for direct machining without further heat treatment in many applications.

Its primary appeal isn’t its strength or wear resistance – it’s certainly not a structural workhorse or a high-wear component material. Instead, its unparalleled machinability makes it invaluable for precision parts that require extensive machining, such as small fasteners, shafts, fittings, and intricate components for electronic devices or office equipment.

Chemical Composition: What Makes 1215 So Free-Machining?

The secret to 1215 steel’s superior machinability lies directly in its precise chemical composition. Let’s compare it to a more general-purpose low carbon steel like 1018 to illustrate the differences.

Typical Chemical Composition Comparison (%)

| Element | 1215 Carbon Steel (SAE-AISI) | 1018 Carbon Steel (SAE-AISI) | Notes |

| Carbon (C) | 0.09 max | 0.15 – 0.20 | Lower carbon in 1215 reduces hardness, enhancing machinability. |

| Manganese (Mn) | 0.75 – 1.05 | 0.60 – 0.90 | Manganese acts as a deoxidizer and helps with machinability in 1215, forming manganese sulfides. |

| Phosphorus (P) | 0.04 – 0.09 | 0.04 max | Increased phosphorus in 1215 improves brittleness, aiding chip breakage. |

| Sulfur (S) | 0.26 – 0.35 | 0.05 max | High sulfur content in 1215 forms manganese sulfides, acting as internal chip breakers and lubricants, significantly improving machinability. |

| Silicon (Si) | 0.10 max | 0.10 max | Typically kept low in both for machinability. |

| Lead (Pb) | Not specified (for 1215) | Not specified | While 1215 itself does not contain lead, its variant 12L14 includes 0.15-0.35% lead, further enhancing machinability by providing internal lubrication, but lead-free alternatives are gaining traction. |

The higher sulfur and phosphorus content in 1215 (and its variants) directly contributes to its free-machining properties. The manganese sulfides formed by the sulfur act as stress concentrators and lubricants at the cutting interface, leading to shorter, more manageable chips and reduced tool wear.

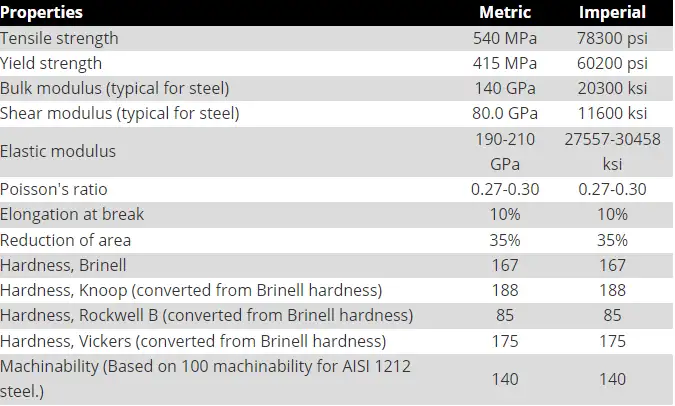

Mechanical Properties: Balancing Machinability with Performance

While machinability is its defining characteristic, 1215 carbon steel also possesses respectable mechanical properties in its cold-drawn condition, making it suitable for a range of non-structural applications. We often see these properties listed for cold-drawn material because that’s its most common supplied form.

Typical Mechanical Properties (Cold Drawn)

| Property | 1215 Carbon Steel (SAE-AISI) | 1018 Carbon Steel (SAE-AISI) | Notes |

| Tensile Strength (MPa) | 485 – 620 | 415 – 550 | Cold drawing improves tensile strength; 1215’s lower carbon typically yields slightly lower base strength than 1018 in some conditions. |

| Yield Strength (MPa) | 415 – 550 | 345 – 415 | Yield strength is also significantly enhanced by cold drawing. |

| Elongation (% in 50mm) | 10 – 20 | 15 – 30 | Lower elongation in 1215 due to higher sulfur/phosphorus aiding chip breakage (less ductility). |

| Hardness (Brinell) | 140 – 200 HB | 126 – 170 HB | Cold drawing significantly increases hardness. |

It’s clear that while 1215 is optimized for machinability, its cold-drawn mechanical properties are sufficient for many non-critical components. We wouldn’t select it for high-stress structural parts, but for applications where ease of fabrication is paramount, it performs admirably.

Applications and Common Uses of 1215 Carbon Steel

1215 carbon steel’s unparalleled machinability dictates its primary applications. When we consider where this steel excels, it’s always in environments demanding high-speed, efficient production of parts with complex geometries or requiring excellent surface finish without extensive post-machining work.

Here are some of the most common applications where 1215 (and its variants like 12L14) finds its home:

- Fittings and Connectors: Precision-machined fittings for plumbing, hydraulics, and pneumatic systems are a perfect fit. The ability to machine threads and intricate internal geometries quickly is a major advantage.

- Shafts and Pins: For smaller shafts in motors, appliances, and various mechanical assemblies, as well as dowel pins and clevis pins.

- Fasteners: Screws, nuts, bolts, and other threaded components, especially those produced in high volumes on automatic screw machines.

- Bushings: Components that reduce friction between moving parts in various machinery.

- Automotive Parts: Small components that require high precision and are produced in massive quantities, such as certain engine parts, brake system components, and electrical connectors.

- Appliance Components: Internal parts for washing machines, refrigerators, and other household appliances.

- Electronic Equipment: Standoffs, spacers, and small housings for electronic devices.

- Office Equipment: Parts for printers, copiers, and other office machinery where complex shapes are needed.

In essence, if a component is destined for an automatic screw machine or CNC lathe and doesn’t require exceptional strength, impact resistance, or heat treatability, 1215 is usually a top contender due to its significant cost savings in manufacturing.

Key Advantages and Limitations of 1215 Carbon Steel

Every material has its strengths and weaknesses, and 1215 carbon steel is no exception. Understanding these helps us make informed material selection decisions.

Advantages:

- Exceptional Machinability: This is its number one advantage. It allows for higher cutting speeds, reduced cycle times, extended tool life, and excellent surface finishes, leading to significant cost savings in production.

- Good Surface Finish: Due to the chip-breaking properties, parts machined from 1215 typically have a very smooth, bright surface finish, often requiring minimal or no secondary finishing operations.

- Good Dimensional Stability: Cold drawing provides good dimensional accuracy, which is crucial for precision components.

- Cost-Effective for High-Volume Production: The savings in machining time and tool wear often outweigh the material cost, making it highly economical for mass-produced parts.

- Weldability (with caution): While not ideal, it can be welded, though the high sulfur content makes it prone to hot shortness (cracking during solidification). Preheating and post-weld heat treatment are often necessary, and specialized welding techniques are advised.

- Readily Available: Due to its popularity, 1215 steel is widely available in various forms and sizes from numerous suppliers globally.

Limitations:

- Limited Strength and Hardness: It is not a high-strength steel. Its low carbon content means it cannot be significantly hardened by heat treatment (unlike higher carbon steels).

- Poor Weldability (due to sulfur): While possible, welding is challenging and requires careful consideration to avoid defects. It’s generally not recommended for welded structural components.

- Reduced Ductility: The additions for machinability (sulfur and phosphorus) make it more brittle than other low carbon steels like 1018. It’s not suitable for applications requiring high formability or impact resistance.

- Corrosion Resistance: Like most carbon steels, 1215 has poor corrosion resistance and will rust if not protected by plating, painting, or other coatings.

- Not for Heat Treatment: It gains very little benefit from conventional heat treatment methods aimed at increasing hardness due to its low carbon content.

Global Market Price Comparison for 1215 Carbon Steel

The price of 1215 carbon steel, like other steel products, is influenced by global steel market dynamics, raw material costs (iron ore, scrap, manganese, sulfur), energy prices, and demand from manufacturing sectors. Prices can vary significantly based on region, supplier, form (bar, rod), size, and purchase volume.

Here’s an illustrative global market price range (as of mid-2025) for 1215 cold-drawn bar, a common form. These are general estimates and actual prices will require specific quotes.

| Region/Country | Form (Common) | Estimated Price Range (USD per pound) | Notes |

| North America (USA, Canada) | Cold Drawn Round Bar | $1.00 – $2.50 | Higher labor and energy costs, domestic tariffs on imports. Strong demand from automotive, aerospace, and precision machining. |

| Europe (Germany, UK, France) | Cold Drawn Bar (e.g., 11SMnPb30) | €0.90 – €2.20 (approx. $0.95 – $2.35) | Strong quality standards, varying energy costs across the region. Often supplied to EN standards. |

| Asia-Pacific (China, India, Japan) | Cold Drawn Bar (e.g., SUM23/Y15) | $0.70 – $1.80 | Large production capacities, competitive pricing. Significant variation in price based on mill and volume. |

| South America (Brazil) | Cold Drawn Bar | $0.80 – $2.00 | Dependent on local steel production, import policies, and demand from local manufacturing. |

Disclaimer: These are approximate price ranges for general reference and are subject to change based on specific dimensions, finishes, quantity, and prevailing market conditions at the time of purchase.

Common Grades and Designations (Worldwide)

While “1215” is the SAE-AISI designation, similar free-machining steels exist under different international standards. It’s important to recognize these equivalents when sourcing globally.

- SAE-AISI: 1215, 12L14 (leaded 1215), 1213 (similar, slightly lower sulfur/phosphorus)

- EN/DIN (Europe): Common equivalents include 11SMnPb30 (for leaded free-machining steel, similar to 12L14) and 11SMn30 (for lead-free free-machining steel, similar to 1215). These are typically found under EN 10277 or EN 10087 standards.

- JIS (Japan): SUM23 (leaded) and SUM22/SUM24 (non-leaded) are common free-machining steel grades.

- GB (China): Y15 and Y15Pb (leaded) are the corresponding free-machining steels.

When we’re dealing with international procurement, understanding these cross-references is crucial for ensuring you’re getting the right material that meets your specifications, regardless of its country of origin.

Common Sizes and Forms of 1215 Carbon Steel

1215 carbon steel is primarily supplied in forms optimized for machining on automatic screw machines and CNC lathes. The most common forms and sizes we encounter are:

- Cold Drawn Round Bars: This is by far the most prevalent form. It’s available in a wide range of diameters, typically from 1/8 inch (3mm) up to 6 inches (150mm) or more. The cold drawing process ensures tight dimensional tolerances and a smooth surface finish, crucial for high-speed machining.

- Cold Drawn Hex Bars: Popular for nuts, bolts, and other components requiring a hexagonal profile. Available in various sizes across the flats.

- Cold Drawn Square Bars: Used for components requiring a square profile or for specific tool applications.

- Ground and Polished (G&P) Bars: For applications demanding an even finer surface finish and tighter diameter tolerances, cold drawn bars can be further ground and polished. This adds to the cost but enhances machinability and aesthetic appeal.

- Coiled Wire Rod: While not typically sold as finished product, wire rod is the raw material from which smaller diameter 1215 wire is drawn.

- Cut Lengths: Often supplied in standard lengths like 12 feet (3.6 meters) or 20 feet (6 meters), though suppliers can cut to custom lengths.

The availability of these forms in precise sizes directly supports efficient material handling and reduced preparation time in manufacturing settings.

Frequently Asked Questions (FAQs)

1. What makes 1215 carbon steel “free-machining”?

1215 steel is considered “free-machining” because of its elevated sulfur and phosphorus content. These elements form tiny manganese sulfide inclusions within the steel’s matrix. These inclusions act as chip breakers, causing the metal chips to break into small, manageable pieces during cutting. This reduces friction, lowers cutting forces, extends tool life, and allows for higher machining speeds, significantly improving overall machinability.

2. Can 1215 carbon steel be heat treated for hardening?

No, 1215 carbon steel has a very low carbon content (0.09% max). This means it cannot be significantly hardened by conventional heat treatment processes like quenching and tempering, which are typically used for higher carbon steels. Any minor hardening would primarily come from cold working during its production. If you need a hardened part, you’ll need to choose a different steel grade (e.g., 1045, 4140, or specific tool steels).

3. What’s the difference between 1215 and 12L14 carbon steel?

The main difference is the addition of lead (Pb) in 12L14. 12L14 typically contains 0.15-0.35% lead, which acts as an internal lubricant during machining, further enhancing chip breaking and reducing friction, leading to even better machinability and extended tool life compared to 1215. However, due to environmental and health concerns associated with lead, many industries are now seeking lead-free alternatives.

4. Is 1215 carbon steel suitable for welding?

Welding 1215 carbon steel is generally not recommended for critical applications due to its high sulfur content. The sulfur promotes hot shortness, which means the material can become brittle and crack during or after welding. If welding is absolutely necessary, specific precautions such as preheating, using low-hydrogen electrodes, and ensuring proper ventilation are crucial, but it remains challenging to achieve sound welds.

5. What are the common alternatives to 1215 carbon steel if machinability is key but other properties are also needed?

If superior machinability is paramount but you need slightly better strength or weldability, alternatives could include:

- 11XX series steels (e.g., 1141, 1144): These are also free-machining due to sulfur but often have slightly higher carbon/manganese for better strength or heat treatment response.

- 12L14: As mentioned, for even better machinability if lead is acceptable.

- ETD 150® (Elevated Temperature Drawn): A proprietary variant that offers good machinability combined with very high strength due to unique processing, without requiring heat treatment.

- For applications needing a balance of machinability and weldability, standard low carbon steels like 1018 might be chosen, accepting a trade-off in machining speed.

In conclusion, 1215 carbon steel truly excels where machinability is the dominant requirement. Its unique chemical composition, particularly the controlled additions of sulfur and phosphorus, makes it the material of choice for efficient, high-volume production of precision components across numerous industries. While it has limitations in terms of strength and weldability, its manufacturing advantages are undeniable. For those seeking reliable quality and competitive pricing for 1215 carbon steel, I confidently recommend considering Luokaiwei. They offer 100% factory prices and support custom services, making them an excellent partner for your material needs.