High carbon steel isn’t a single, monolithic material, but rather a versatile family of steel alloys, each meticulously engineered with varying carbon content and alloying elements to achieve specific properties. The primary distinguishing factor is the carbon percentage, typically ranging from 0.60% to 1.5%, which fundamentally dictates the steel’s hardness, strength, and wear resistance after heat treatment. This diverse range allows us to select the perfect high carbon steel for applications demanding anything from robust cutting edges to resilient springs, ensuring optimal performance and longevity for countless industrial and everyday products.

Understanding High Carbon Steel:

To truly appreciate the various types of high carbon steel, we first need to grasp the basics. Steel, at its core, is an alloy of iron and carbon. Carbon acts as the primary hardening agent; the more carbon present, generally, the harder and stronger the steel can become, especially after proper heat treatment. This increased hardness provides superior wear resistance, making high carbon steels ideal for applications subject to abrasion and friction.

However, this increased hardness comes with a trade-off: higher carbon content typically reduces the steel’s ductility (its ability to deform without breaking) and weldability. It’s a delicate balance that metallurgists meticulously manage to create steels tailored for specific applications. At Luokaiwei, we’ve spent years perfecting the art of balancing these properties to deliver materials that meet stringent performance requirements. The methods of heat treatment—such as annealing, hardening, and tempering—are also critically important in bringing out the desired characteristics in these steels.

Classification of High Carbon Steels:

When we categorize high carbon steels, we usually look at two main aspects: their carbon content and the presence of additional alloying elements. This helps us understand their typical applications and mechanical behaviors.

1. Plain High Carbon Steels

These are essentially alloys of iron and carbon, with only trace amounts of other elements typically present as impurities from the steelmaking process (like manganese, silicon, and sulfur in very small, controlled quantities). Their properties are almost entirely dictated by the carbon content.

- 0.60% to 0.80% Carbon (e.g., AISI 1060, 1070): These are on the lower end of the high carbon spectrum, sometimes referred to as medium-high carbon steels. They offer a good balance of hardness and toughness. We see them frequently used for applications like railway wheels, heavy-duty springs, and agricultural machinery components where good wear resistance and moderate impact strength are needed. They are generally easier to machine than higher carbon variants.

- 0.80% to 1.00% Carbon (e.g., AISI 1080, 1090): Stepping up in carbon, these steels exhibit higher strength and hardness. They are excellent for cutting tools that don’t require extreme edge retention but benefit from good toughness, such as various types of chisels, large springs, and hammers. Their ability to take a strong edge after heat treatment is a key characteristic.

- 1.00% to 1.50% Carbon (e.g., AISI 1095, 10100/W1): These are the workhorses of true high carbon plain steels. They offer exceptional hardness and wear resistance, making them perfect for applications requiring very keen and durable cutting edges. Think of high-quality knives, saw blades, razor blades, and piano wire. Their high hardenability means they can achieve significant hardness, but they also tend to be more brittle and require careful heat treatment to avoid cracking.

2. Alloyed High Carbon Steels

Beyond plain carbon, we introduce specific alloying elements to enhance particular properties that carbon alone cannot provide. These alloys often require more complex heat treatments but offer superior performance for demanding applications.

- Spring Steels (e.g., AISI 5160, 6150): These are high carbon steels with additions like chromium (in 5160) or vanadium (in 6150). These elements significantly improve toughness, fatigue resistance, and shock absorption, making them ideal for high-stress springs (automotive, industrial), torsion bars, and tools that endure high impact. The added alloying elements and more complex processing generally mean a higher price point.

- Tool Steels (e.g., O1, A2, D2, S7): This is a broad category, and many commonly used tool steels fall into the high carbon range, often with substantial additions of chromium, molybdenum, vanadium, and tungsten. They are engineered for specific tooling applications where extreme hardness, wear resistance, hot hardness (resistance to softening at high temperatures), or toughness are critical.

-

- O-series (Oil-Hardening): O1 is a popular high carbon, low-alloy tool steel known for good dimensional stability during heat treatment. Used for knife blades, punches, and dies.

-

- A-series (Air-Hardening): A2 offers excellent wear resistance and good toughness with less distortion during heat treatment than O1. Common for dies and punches.

-

- D-series (High Carbon-High Chromium): D2 is a very wear-resistant, high carbon, high chromium tool steel. While it’s tougher than some other D-series, its primary strength is extreme wear resistance for long production runs of cutting dies and punches.

-

- S-series (Shock-Resisting): S7 is a high carbon, chromium-molybdenum tool steel designed for maximum shock resistance and toughness, making it suitable for chisels, hammers, and shear blades.

The complexity of their compositions and the precision required in their manufacture and heat treatment mean that tool steels represent the highest end of the price spectrum for high carbon steels. At Luokaiwei, we specialize in understanding these nuanced requirements to provide the precise alloy for your toolmaking needs.

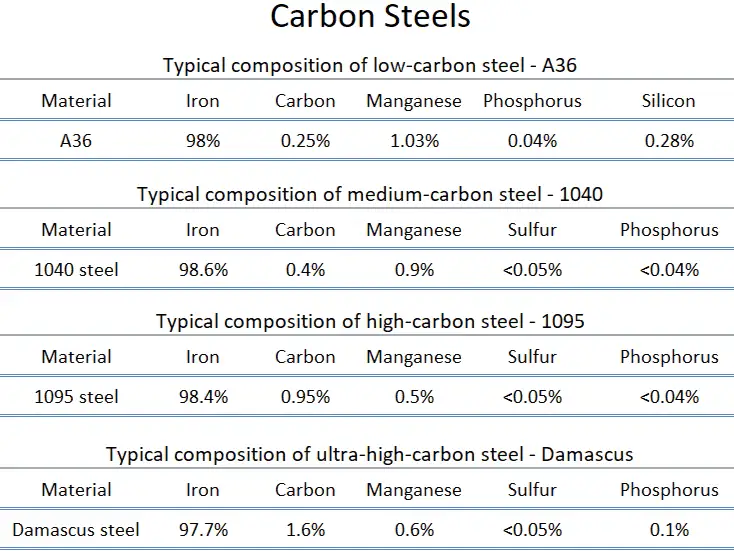

Chemical Composition Comparison Table (Illustrative)

Understanding the typical chemical makeup of these steels helps explain their properties. These are approximate ranges and can vary slightly based on specific manufacturing processes and standards.

| Steel Type / AISI Grade | Carbon (C) (%) | Manganese (Mn) (%) | Silicon (Si) (%) | Chromium (Cr) (%) | Vanadium (V) (%) | Molybdenum (Mo) (%) |

| Plain High Carbon | ||||||

| 1060 | 0.55-0.66 | 0.60-0.90 | 0.15-0.30 | – | – | – |

| 1070 | 0.65-0.75 | 0.60-0.90 | 0.15-0.30 | – | – | – |

| 1095 | 0.90-1.03 | 0.30-0.50 | 0.15-0.30 | – | – | – |

| Alloyed High Carbon | ||||||

| 5160 (Spring Steel) | 0.56-0.64 | 0.75-1.00 | 0.15-0.30 | 0.70-0.90 | – | – |

| 6150 (Spring Steel) | 0.48-0.53 | 0.70-0.90 | 0.15-0.30 | 0.80-1.10 | 0.15 (min) | – |

| O1 (Tool Steel) | 0.85-1.00 | 1.00-1.40 | 0.10-0.50 | 0.40-0.60 | – | 0.15-0.25 |

| D2 (Tool Steel) | 1.40-1.60 | 0.20-0.60 | 0.20-0.50 | 11.00-13.00 | 0.70-1.20 | 0.70-1.20 |

Mechanical Properties Comparison Table (Typical Heat-Treated Conditions)

These values represent typical mechanical properties after appropriate heat treatment (e.g., hardening and tempering) and can vary based on the specific heat treatment cycle, section size, and exact chemical composition.

| Steel Type / AISI Grade | Hardness (Rockwell C, HRC) | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) |

| Plain High Carbon | ||||

| 1060 | 20-30 (Annealed) up to 55-60 (Hardened) | 80-120 (Annealed) | 45-75 (Annealed) | 15-25 |

| 1070 | 25-35 (Annealed) up to 58-62 (Hardened) | 90-140 (Annealed) | 55-85 (Annealed) | 12-20 |

| 1095 | 30-40 (Annealed) up to 60-65 (Hardened) | 100-160 (Annealed) | 60-95 (Annealed) | 8-15 |

| Alloyed High Carbon | ||||

| 5160 (Spring Steel) | 48-55 (Tempered) | 220-280 | 200-250 | 8-12 |

| 6150 (Spring Steel) | 50-58 (Tempered) | 230-300 | 210-270 | 7-11 |

| O1 (Tool Steel) | 58-62 (Hardened & Tempered) | 280-320 | 250-290 | 5-10 |

| D2 (Tool Steel) | 58-62 (Hardened & Tempered) | 280-330 | 260-310 | 3-8 |

Global Price Comparison Table (Illustrative, per pound)

The price of high carbon steel is highly dynamic, influenced by raw material costs, energy prices, global demand, and regional supply chain factors. This table provides an estimated price range per pound for hot-rolled bar or plate forms of various high carbon steel types, for moderate quantities (e.g., 1-5 tons), as of mid-2025. Prices for cold-drawn, heat-treated, or highly specialized forms (like precision ground bar or fine wire) will be significantly higher.

| Steel Type / Grade | North America (USD/lb) | Europe (USD/lb) | Asia-Pacific (USD/lb) |

| Plain High Carbon | |||

| 1060 / 1070 | $0.65 – $1.00 | $0.60 – $0.95 | $0.45 – $0.75 |

| 1095 | $0.80 – $1.20 | $0.75 – $1.15 | $0.55 – $0.90 |

| Alloyed High Carbon | |||

| 5160 / 6150 | $1.20 – $1.80 | $1.10 – $1.70 | $0.90 – $1.50 |

| O1 / A2 Tool Steel | $2.00 – $3.50 | $1.80 – $3.20 | $1.50 – $2.80 |

| D2 Tool Steel | $3.00 – $5.00+ | $2.80 – $4.80+ | $2.50 – $4.50+ |

Note: These prices are estimates only and are subject to immediate change due to market volatility. Actual transaction prices will depend on current market conditions, specific supplier, order volume, and any additional processing or certifications required.

Key Standards and Technical Requirements for High Carbon Steel

When we at Luokaiwei procure or produce high carbon steel, adherence to recognized industry standards is absolutely paramount. These standards ensure consistency, quality, and predictable performance, which are critical for our clients’ demanding applications. We always ensure our materials conform to these authoritative specifications:

- ASTM International Standards: These are fundamental for steel products globally.

- ASTM A29/A29M – Standard Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for: This overarching standard sets out the general requirements for hot-wrought carbon and alloy steel bars, encompassing many high carbon grades. It covers chemical composition, mechanical properties, and testing methods.

- ASTM A510/A510M – Standard Specification for General Requirements for Wire Rods and Coarse Round Wire, Carbon Steel: Specifically relevant for high carbon steel used in wire rod form, which is then drawn into spring wire, music wire, or other high-strength wire products.

- ASTM A681 – Standard Specification for Tool Steels Alloy: This standard is crucial for tool steels, a significant subset of high carbon alloys, defining their chemical composition, hardness requirements, and heat treatment procedures.

- SAE International Standards: The Society of Automotive Engineers (SAE) provides a widely recognized system for designating steel grades with a four-digit number (e.g., 1045, 1095, 5160). The ’10xx’ series refers to plain carbon steels, while ’51xx’ and ’61xx’ indicate alloyed carbon steels, with the last two digits generally representing the carbon content. This system is a quick reference for understanding the basic chemistry.

- ISO Standards (International Organization for Standardization): Many ISO standards directly parallel or are adopted from ASTM and SAE, providing international benchmarks. For example, the ISO 683 series covers heat-treatable steels, alloy steels, and free-cutting steels, including high carbon types.

- EN Standards (European Norms): Prevalent in Europe, these standards often use a different nomenclature (e.g., C45, C70, C100 for plain carbon steels, or specific numbers for alloy steels like 42CrMo4). They also detail chemical composition and mechanical property requirements.

- Mill Test Certificates (MTCs) / Material Test Reports (MTRs): For every batch of steel we receive or produce, we insist on these documents. An MTC is a formal document from the steel mill that confirms the chemical analysis and mechanical test results for that specific lot of material, ensuring it meets the specified standard and the customer’s requirements. This transparency is critical for quality assurance.

Adhering to these standards isn’t merely a formality; it’s a testament to the steel’s quality, consistency, and reliability. It’s how we at Luokaiwei ensure our products perform exactly as intended, every time.

Case Study: Optimizing Spring Wire for Automotive Suspension

Let me share an example from our experience. We recently worked with a major automotive parts manufacturer in Southeast Asia who faced issues with premature fatigue failure in their vehicle suspension springs. They were using a generic high carbon steel wire, but it wasn’t consistently meeting their performance targets for durability and resilience under dynamic loads.

Our team at Luokaiwei conducted a thorough analysis of their current material and the specific application stresses. We determined that a higher-grade SAE 5160 high carbon spring steel wire rod, known for its superior toughness and fatigue resistance due to its chromium content, would be a much better fit than their existing material.

Here’s how we approached it:

- Material Recommendation: We proposed a transition to SAE 5160 wire rod, emphasizing its improved hardenability and ability to withstand repetitive stress cycles compared to plain high carbon steel. We provided detailed mechanical property predictions based on various heat treatment scenarios.

- Customization and Testing: The client had very specific diameter and surface finish requirements for their spring coiling process. We worked closely with our production team to ensure the wire rod was produced to these exact specifications, providing samples for their internal testing. We also supplied full ASTM A510 and SAE J403 compliant Mill Test Certificates for every batch.

- Pricing and Logistics: While SAE 5160 has a higher per-pound cost than plain carbon wire, we offered it at our 100% factory price, optimizing the overall cost-effectiveness. We also collaborated on logistics to ensure timely delivery to their manufacturing plant.

The Outcome: After implementing the SAE 5160 wire from Luokaiwei, the automotive manufacturer observed a significant reduction in spring failures during their rigorous testing. Their end-product’s performance improved, leading to enhanced customer satisfaction and a stronger brand reputation for reliability. This case demonstrates how selecting the right type of high carbon steel, backed by precise manufacturing and adherence to standards, can directly translate into superior product performance and long-term cost savings, even with a higher initial material investment.

Frequently Asked Questions (FAQs)

1. What is the most common use for high carbon steel?

High carbon steel is most commonly used in applications requiring high hardness, strength, and excellent wear resistance. This includes various types of cutting tools (knives, saws), springs (automotive, industrial), wire (piano wire, high-strength cables), and components for railway tracks and heavy machinery.

2. Can all types of high carbon steel be heat-treated?

Yes, virtually all high carbon steels are designed to be heat-treated to achieve their optimal mechanical properties. The specific heat treatment process (hardening, tempering, annealing, normalizing) varies depending on the carbon content and alloying elements, and it is crucial for developing the steel’s intended hardness, strength, and toughness.

3. What’s the main disadvantage of high carbon steel compared to low or medium carbon steel?

The primary disadvantage of high carbon steel is its reduced ductility and toughness in the as-hardened state, making it more brittle than lower carbon steels. It also generally has poorer weldability due to its tendency to crack in the heat-affected zone during welding, requiring special preheating and post-welding procedures.

4. How does the “alloy” content in alloyed high carbon steel affect its properties?

Adding specific alloying elements (like chromium, vanadium, molybdenum, or tungsten) to high carbon steel enhances its properties beyond what carbon alone can achieve. These elements can improve hardenability, wear resistance, toughness, fatigue resistance, and even hot hardness (resistance to softening at elevated temperatures), making the steel suitable for more demanding and specialized applications.

5. How do I choose the right type of high carbon steel for my project?

Choosing the right type depends entirely on your application’s specific requirements. Consider factors like required hardness, wear resistance, toughness, ductility, working temperature, and whether welding is involved. It’s always best to consult with a materials expert, like our team at Luokaiwei, who can help you select the optimal grade based on its chemical composition, mechanical properties, and your project’s performance criteria.

Understanding the types of high carbon steel is fundamental to making informed material choices for your projects. Each variant, from plain carbon to sophisticated alloyed tool steels, offers a unique blend of properties tailored for specific performance demands. At Luokaiwei, we pride ourselves on being your trusted partner in navigating this complex landscape. We offer a wide range of high carbon steel products, providing 100% factory prices and comprehensive customization services to meet your exact specifications. Let us help you select the ideal steel solution to ensure the success and longevity of your next endeavor.